Soil stabilization is the method of changing a natural soil to meet an engineering purpose. Improvements include increasing the weight bearing capabilities, tensile strength, and overall performance of in-situ subsoils, sands, and waste materials in order to strengthen road pavements.

Some of these new soil stabilizing techniques create hydrophobic surfaces and mass that prevent road failure from water penetration or heavy frosts by inhibiting the ingress of water into the treated layer. However, recent technology has increased the number of traditional additives used for soil stabilization purposes. You can see some of these in action on social profiles like those of Danny Wang or Ray Garver.

Among the various soil stabilization procedures, the most suitable one is selected depending upon the type of soil available, time, cost involved etc.

Different types of soil stabilization

There are three broad types of soil stabilization: biological, physical and chemical.

Biological soil stabilization is achieved through afforestation or planting, and its main purpose is erosion control. Root traits such as architectural, morphological, physiological and biotic play an important role in both the physical and chemical development of soils enabling structural stability of the soil. This method is suitable for terrain exposed to water and wind influences, which are not meant for building.

Physical soil stabilization is the modification of soil particle size distribution and plasticity by the addition or subtraction of different soil fractions in order to modify its physical properties. Mechanical stabilization is the modification of soil porosity and interparticle friction or interlock. The two methods work synergistically together to yield soil stabilization. Physical and mechanical types of soil stabilization include five different types of techniques namely; compaction, pre-wetting, wetting-drying cycles, reinforcement and solid wastes.

Chemical types of soil stabilization can be achieved through use of traditional and non-traditional agents. The distinction between the two classes exists as a result of the pre-existing and well-established additives as compared to the most recently developed agents. Examples of traditional chemical stabilization agents include lime, cement and fly ash and they are usually calcium based. On exposure to water, they undergo both short- and long-term chemical changes resulting in overall enhancement of the soil matrix with regards to swell reduction, shear strength improvement and resistance to influence of wetting and drying.

Methods for soil stabilization

Vibro compaction method

Vibro Compaction is an established ground improvement method for stabilising granular soils such as loose sands, gravels and some hydraulic fills. The technique is primarily used for seismic mitigation and in-situ densification of loose sands up to 30m deep. The water jetting and horizontal vibratory action of the vibroflot acts to compact the loose soils into a denser condition and significantly improve the bearing capacity of the treated ground. The vibro compaction technique is well established for use in tank farm, port and marine structure projects.

Vibro Compaction significantly reduces the threat of liquefaction in the event of earthquakes; densifying sands to provide a firm founding layer It is extremely effective for sand compaction and land reclamation projects. Vibro Compaction provides fast, in-situ densification of loose sands to depths of up to 30 metres and is one of the most economical and sustainable ground improvement methods available, with no spoil generated and no fill material required.

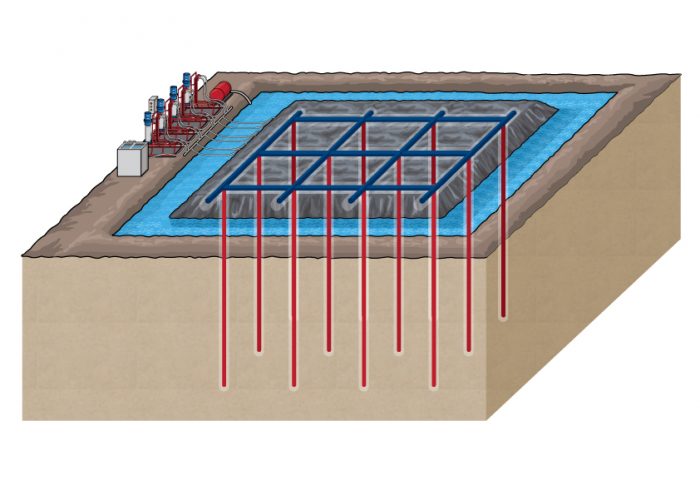

Vacuum consolidation method

Vacuum consolidation is a soft soil improvement method that has been successfully used by geotechnical engineers and specialists of ground improvement companies. It does not necessarily require surcharge fill and vacuum loads of 80kPa or greater can, typically, be maintained for as long as required. However, if loads of 80kPa or greater are needed in order to achieve the target soil improvement, additional surcharge may be placed on top of the vacuum system. The vacuum preloading method is cheaper and faster than the fill surcharge method for an equivalent load in suitable areas. Where the underlying ground consists of permeable materials, such as sand or sandy clay, the cost of the technique will be significantly increased due to the requirement of cut-off walls into non-permeable layers to seal off the vacuum.

Soil Preloading method

Depending on how a preload is applied, the preloading methods can be subdivided into preloading using fill, preloading using vacuum pressure and combined fill, and vacuum preloading methods. In addition to preloading, PVDs have also been used for some other relatively new methods such as dynamic consolidation for clays. In both cases, the main purpose of using PVDs is to reduce the drainage path so that the time taken for the consolidation of soft soil or the dissipation of excess pore-water pressure can be substantially reduced.

Soil vitrification method

Soil Vitrification technique uses heat to melt and then solidify harmful chemicals in a solid mass of glasslike material. It can be applied both in-situ (in-situ vitrification or ISV) and above ground in a treatment unit (ex-situ). ISV uses space and an electrical current is passed between them, melting the soil between them. ISV uses very high temperatures (1,600 to 2,000 °C or a pair of, 900 to 3,650 °F). Melting starts close to the bottom surface and moves downEx-situ vitrification is far like ISV, except that it’s done within a compartment. Heating devices embody plasma torches and electrical transference furnaces. With plasma torch technology, waste is fed into a rotating hearth; the waste and melted material square measure control aligned with the aspect by force. Throughout the rotation, the waste moves through plasma generated by a standstill torch.

Ground freezing method

Ground freezing is a construction technique used in circumstances where soil needs to be stabilized so it will not collapse next to excavations, or to prevent contaminants spilled into soil from being leached away. Ground freezing has been used for at least one hundred years. Ground freezing is also used to provide regional groundwater barriers around mining operations for gold and other minerals, oil sands or oil shales. It is often referred to as ground freezing, soil freezing, or freeze wall. The ground freezing process involves drilling and installing a series of relatively closely spaced pipes and circulating a coolant through these pipes.

Vibro stone columns

Vibro stone columns or aggregate piers are an array of crushed stone pillars placed with a vibrating tool into the soil below a proposed structure. This method of ground improvement is also called vibro replacement. Such techniques increase the load bearing capacity and drainage of the soil while reducing settlement and liquefaction potential. Stone columns are made across the area to be improved in a triangular or rectangular grid pattern.

Mechanically stabilized earth (MSE) method

Mechanically stabilized earth (MSE or reinforced soil) is soil constructed with artificial reinforcing. It can be used for retaining walls, bridge abutments, seawalls, and dikes.[ Although the basic principles of MSE have been used throughout history. MSE walls stabilize unstable slopes and retain the soil on steep slopes and under crest loads. The wall face is often of precast, segmental blocks, panels or geocells that can tolerate some differential movement. The walls are infilled with granular soil, with or without reinforcement, while retaining the backfill soil. Reinforced walls utilize horizontal layers typically of geogrids. The reinforced soil mass, along with the facing, forms the wall. In many types of MSE’s, each vertical fascia row is inset, thereby providing individual cells that can be infilled with topsoil and planted with vegetation to create a green wall.

Soil nailing method

Soil nailing is a ground stabilisation technique that can be used on either natural or excavated slopes. It involves drilling holes for steel bars to be inserted into a slope face which are then grouted in place. Mesh is attached to the bar ends to hold the slope face in position. They are commonly used as a remedial measure to stabilise embankment. Soil nailing uses grouted, tension-resisting steel elements (nails) to reinforce in situ soils and creates a gravity retaining wall for permanent or temporary excavation support.Soil nail walls are generally constructed from the top down.

Conclusion

While deciding upon methods of soil stabilization one needs to accelerate bearing capability, enhance shear strength and decrease consolidation settlement of saturated medium clay such as soil replacement, preloading with vertical drains, stone columns, stabilization with additives and thermal ways.