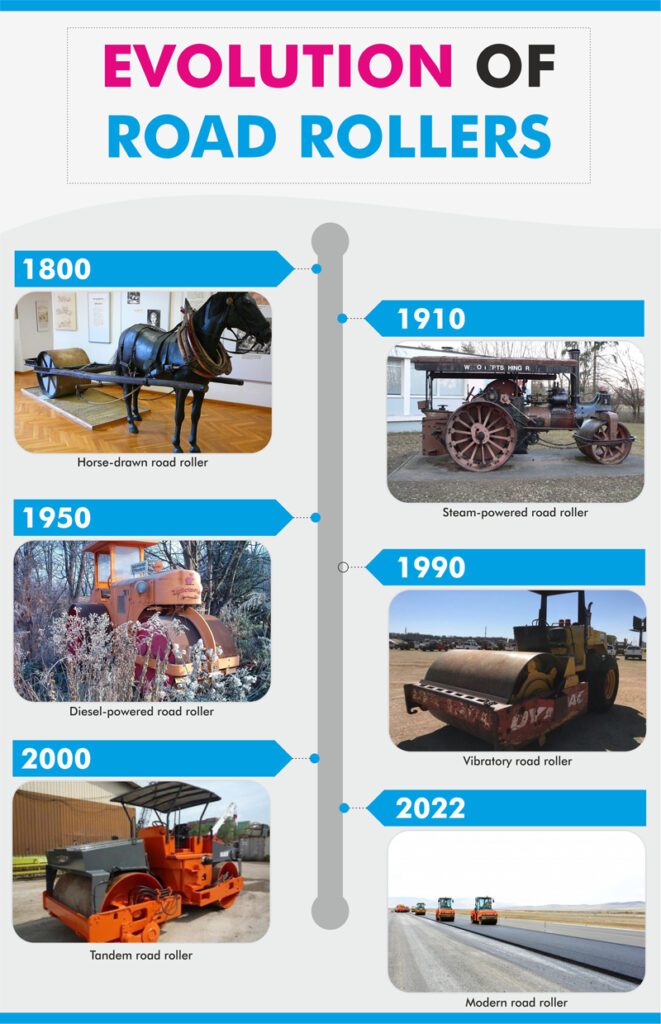

Did you know that the first road rollers were horse-drawn?

Road rollers were once powered by strong animals such as horses. Once steam power was introduced, self-powered road rollers became more popular. Steam rollers are similar to tractions engines which became the inspiration for road roller designs. During the 19th century, people started building roads with concrete, mixing aggregates, asphalt and clay. This road type was soft and tough. As a result, people made use of the transformed rollers to flatten and harden roads. This is actually how the road roller came about. During the 20th century, rollers powered by kerosene, gasoline, and diesel replaced their steam-powered counterparts. With time road rollers have now evolved.

Modern road rollers

Road construction sites need stable ground to do their work on. The soil needs to be compressed so there aren’t any pockets of air underground that can disrupt the process. One of the most common types of equipment used for the purpose is the road roller. It is utilised for creating compact foundations for large areas. The primary use for road rollers is to crush, knead or vibrate loose materials by applying direct pressure.

To meet the National Highways Authority of India’s ambitious target to build new highways, manufacturers are now focusing on road roller’s engine performance for fuel-efficiency. The selection of the right road construction equipment becomes pivotal. The road roller is one such important piece of equipment that plays an important role in road construction. It is most often used for road construction or for creating compact foundations for large areas. The trend of incorporation of autonomous and semi-autonomous systems along with fuel-efficient road roller equipment is increasing. Additionally, operator friendliness is a prime focus. A cab design can help make operators comfortable and machine loading easy. Modern road rollers come with a compact design, with articulated maneuverability that requires a lesser turning radius. Safe and ease of maintenance of these machines are enabled by higher drain out and replacement intervals of the drum oil, engine oil and filters. Models also fulfil the requirements of the CEV Stage IV. Discussed below are different types of road rollers used across projects in India.

Types of Road Rollers in India

Pneumatic tyred roller for kneading and sealing effect for job sites

Pneumatic tyred rollers provide the kneading and sealing effect for job sites increasing productivity on tough terrain. These rollers perform on both asphalt and aggregates, which of course means the machines must be flexible. They certainly are, with air pressure adjustments made without the operator ever leaving the cab. Ballast packages easily can be added or removed to ensure the most efficient machine and process are provided. Modern pneumatic rollers can be used on several different projects such as subdivision streets, large parking lots, and driveways. Everything can be easily managed by the operator through a control operation station. The optional Traction Control (ATC) boosts productivity on tough terrain. The proven hydrodynamic propulsion system ensures productivity. Ballast packages easily can be added or removed to ensure the most efficient machine and process are provided. can be used on several different projects such as subdivision streets, large parking lots, and driveways. Operators would find the machine easy to control as it is very user-friendly and easy to operate, it comes with a spacious cab.

Single drum roller for compacting cohesive materials

The modern range is equipped with an air aftercooler system with internal EGR that increases the density of the intake air, improving efficiency and reducing fuel consumption. Coupled with the turbo pre-cleaner, the water-cooled engine ensures excellent cooling and high fuel efficiency. The model also comes attached with a drum drive and clamp-on pad foot for compacting more cohesive materials such as clay and silt The optional drum drive system features an additional high torque drive motor mounted on the front drum frame, resulting in excellent gradeability and optimized traction. There are 4-pins central joints: a heavy-duty design solution to make the machine suitable for the most severe applications. The models are available in three configurations to meet every surface compaction need:

Double drum roller to work in very narrow spaces

The latest modes come with a high steering angle allowing the machines to work in very narrow spaces and increase the compacting accuracy. Thrillers come standard with a hydraulically adjustable “crab steering” system that can offset the rear drum up to seven inches. In addition to that, a heavy-duty, roller-style articulation joint allows the machine to oscillate +/-10° to maintain drum-to-ground contact. Together, these features enable superior operation around corners, over bumps or dips, and in confined areas. The superior drum diameter ensures high compaction quality even in case of very irregular surfaces. The standard pressurised water sprinkler system with 6 nozzles per drum provides longer operating hours in every condition due to optimised water usage and the consistent water flow regardless of the slope of the jobsite. The ergonomically designed sliding operator’s seat allows the driver to have a perfect view on the drum edge in every working condition.

Tandem roller with three-point articulation system

The three-point articulation in the new age tandem rollers guarantees even weight distribution, offers outstanding directional stability, impressive stability when negotiating curves, and a high level of safety against overturning. With a drum width of 1.68 m, they can be used in innercity projects, for compaction on motorways, airports and other large areas. From the operator’s platform on the new tandem rollers, the driver has an excellent view of the construction site. Models fulfil the requirements of the CEV Stage IV criterion. Furthermore, both models offer a modern operator’s platform and excellent driving comfort and handling properties. The combination of a modern engine, large radiator, air flow and engine management leads to reduced noise emissions and up to 10% lower fuel consumption when compared to the predecessor models. The rollers also prove to be convenient when it comes to the daily check and regular maintenance. All access points can be easily accessed from the ground. The service flap on the driver’s platform is new and facilitates access to the turbocharger.

Vibratory rollers to densify soil and asphalt

Modern vibratory rollers densify soil, asphalt or other materials through the application of combined static and dynamic forces to increase the load-bearing capacity of the surface. Vibratory rollers can fully cover the area underneath the wheel. It’s more efficient compared to other road roller types when it comes to compacting. The vibration of the roller can arrange the particles and exerts direct pressure on the specific layer. When the vibratory roller is in reverse, the vibration is briefly turned off to avoid disturbing the compacted area. This type of roller is best used to reduce air voids and for densifying granular soil. The llers are used primarily to compact paving materials, such as asphalt mixes and roller-compacted concrete. Modern machines feature two steel drums that vibrate via an internal, eccentric mechanism, which often can be adjusted to vary the frequency and amplitude of the vibratory action. Some tandem vibratory rollers are also equipped with satellite-navigation and proprietary software systems, continually report the degree of compaction and can map the job site’s compaction values for future reference.

Mini-tandem roller with Automatic Vibration Control system

Latest models come with highly fuel-efficient, maintenance-free vibration systems and articulation joints. The machine’s Automatic Vibration Control system cuts off vibration when the roller stops. Mini Tandem Roller is best suited for applications such as highway road shoulders, retaining the walls of flyovers, footpaths, trenches, service roads, industrial and residential columns, rural roads. This is a versatile roller as it can be used for both earth and asphalt compaction. The drum has an extended life and increased stability during operations due to its great thickness of 13.5mm. This increases the output in less number of passes. The models provide utmost comfort to the operator with its ergonomically located controls, minimising physical effort and maximising efficiency.

Conclusion

The road rollers are essential for those thinking about maximizing their output. Choosing the one that fits the project criteria is the key. There is a tremendous amount of stress that is put on the system and it’s important to start with a reliable solution. With the help of a high-grade road roller, it becomes easier.

Image Source: ammann.com/cn-en/, casece.com, jcb.com/en-in/, wirtgen-group.com, escortsgroup.com, bomag.com/ww-en/