Pervious concrete is a relatively new concept for rural road pavement, with increase into the problems in rural areas related to the low ground water level, agricultural problem. Pervious concrete has introduced in rural road as a road pavement material. Pervious concrete as a paving material has seen renewed interest due to its ability to allow water to flow through itself to recharge groundwater level and minimize storm water runoff. This introduction to pervious concrete pavements reviews its applications and engineering properties, including environmental benefits, structural properties, and durability. In rural area cost consideration is the primary factor which must be kept in mind. So that in rural areas costly storm water management practices is not applicable.

Pervious concrete pavement is unique and effective means to meet growing environmental demands. By capturing rainwater and allowing it to seep into the ground. This pavement technology creates more efficient land use by eliminating the need for retention ponds, swell, and other costly storm water management devices.

INTRODUCTION

Pervious concrete can be used for a number of applications, but its primary use is in road pavement such as in rural areas. This article will focus on the pavement applications of the concrete, which also has been referred to as porous concrete, permeable concrete, no-fines concrete, gap-graded concrete, and enhanced-porosity concrete.

Pervious concrete is a zero-slump, open-graded material consisting of cement, coarse aggregate, admixtures and water. Pervious concrete contains little or no fine aggregates such as sand, it is sometimes referred to as “no-fines” concrete.

Pervious concrete pavement in rural areas is a unique and effective means to achieve important environmental issues and support green, sustainable growth. By capturing storm water and allowing it to seep into the ground, porous concrete is instrumental in recharging groundwater, reducing storm water runoff.

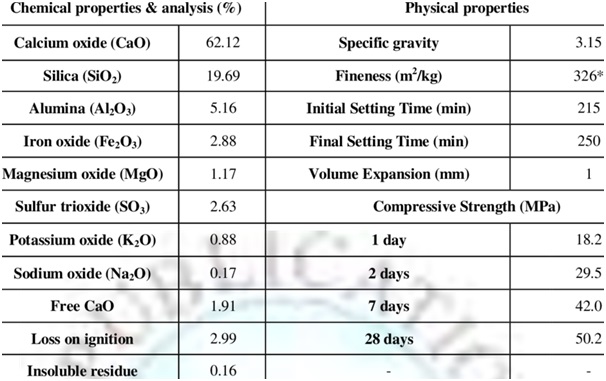

MATERIALS USED IN PERVIOUS CONCRETE

Figure 1: Materials Used in Pervious Concrete

NEED OF PERVIOUS CONCRETE IN RURAL ROAD PAVEMENT

In rural areas larger amount of rainwater ends up falling on impervious surfaces such as parking lots, driveways, sidewalks, and streets rather than soaking into the soil. This creates an imbalance in the natural ecosystem and leads to a host of problems including erosion, floods, ground water level depletion and pollution of rivers, as rainwater rushing across pavement surfaces picks up everything from oil and grease spills to de-icing salts and chemical fertilizers.

A simple solution to avoid these problems is to stop constructing impervious surfaces that block natural water infiltration into the soil. Rather than building them with conventional concrete, we should be switching to Pervious Concrete or Porous Pavement, a material that offers the inherent durability and low life-cycle costs of a typical concrete pavement while retaining storm water runoff and replenishing local watershed systems. Instead of preventing infiltration of water into the soil, pervious pavement assists the process by capturing rainwater in a network of voids and allowing it to percolate into the underlying soil.

PERVIOUS CONCRETE MIX DESIGN

Pervious concrete uses same materials as conventional concrete, except that there are usually No or little fine aggregates. The size of the coarse aggregate used is kept fairly uniform in size (most common is 3/8 inch) to minimize surface roughness and for a better aesthetic, however sizes can vary from ¼ inch to ½ inch. Water to cement ratio should be within 0.27 to 0.34. Ordinary Portland cement and blended cements can be used in pervious concrete. Water reducing admixtures and retarders can be used in pervious concrete. General Issues encountered compared to standards concrete are;

1. Long mixing time in the batching plants (about 20 min)

2. Poor workability, very dry mix, difficult for placing

3. Amount of water used in mix is important as same as standards concrete

4. If too much water used, segregate is expected, usually higher than standards concrete

5. If too little water is used, not easy to mix, balling of mix in the mixer

Table 1: Typical mix design of Pervious Concrete as suggested by ACI 522R-10

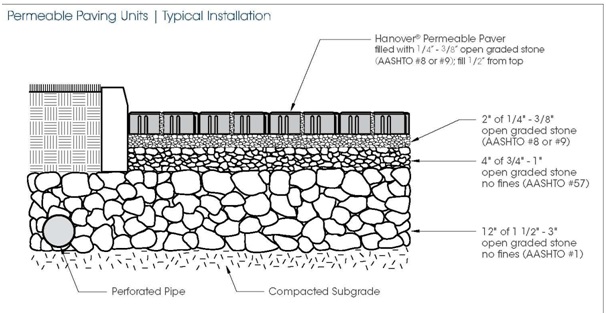

DESIGN PERVIOUS CONCRETE TO CONTROL STORMWATER

Typical cross section of pervious concrete designed for storm water is given in figure.

Curb area: provide to retain flood water, usually 6” layer (100% voids)

Pervious concrete: usually 6” layer (20% voids)

Base or subbase: Compacted metal (stone), usually 6” layer (30% voids)

Subgrade: Compacted existing soil, usually 24” (15% void)

Figure 2: Typical cross section of pervious concrete designed for storm water

BENEFITS OF PERVIOUS CONCRETE

- It reduces the storm water runoff.

- Eliminates the need for detention ponds and other costly storm water management practices.

- Mitigates surface runoff.

- Replenishes the aquifers and water table.

- Allows more efficient land development.

- Prevents water from entering into the stream and also prevents it from being polluted.

APPLICATIONS OF PERVIOUS CONCRETE

- Pervious Concrete as a Road pavement.

- Low-volume pavements.

- Sidewalks and pathways.

- Residential roads and driveways.

- Parking lots.

- Noise barriers.

- Slope stabilization.

- Hydraulic structures.

- Swimming pool decks.

- Tennis courts.

PERVIOUS CONCRETE PROPERTIES

FACTORS TO BE CONSIDERED FOR DESIGNING PERVIOUS CONCRETE PAVEMENT

Pervious concrete used in road pavement systems must be designed to support the intended Traffic Load and contribute positively to the site specific Storm Water Management Strategy. The designer selects the appropriate material properties, the appropriate pavement thickness, and other characteristics needed to meet the hydrological requirements (permeability, volume of voids, amount of rainfall expected, underlying soil properties) and anticipated traffic loads simultaneously.

COST OF POROUS PAVEMENT

The cost of pervious asphalts and stone recharge beds may be higher than standard dense-grade asphalt surfaces due mainly to the amount of materials required for the stone recharge bed. This cost difference however, is offset by the savings in the area of land required by surface storm water retention basins or underground storm water containment systems.

GUIDELINES FOR INSTALLATION OF PERVIOUS CONCRETE

- Pervious concrete pavement shall be installed by certified contractors only.

- Once it is placed, the pervious concrete shall remain covered and undisturbed for seven (7) days. The covering should be waterproof polyethylene sheeting with a minimum thickness of 6 mm. This curing period is essential for adequate strength and durability.

- The use of signage is encouraged during the seven day period to minimize the potential damage to the curing concrete occurring from pedestrian traffic.

PLACEMENT OF PERVIOUS CONCRETE FOR ROADWAY

Figure 3: Placement of Pervious Concrete for Roadway

DIFFERENCE BETWEEN PERVIOUS CONCRETE AND IMPERVIOUS CONCRETE SURFACE

Figure 4: Pervious Vs Impervious Surface

It is clearly shown from the figure-4 that pervious concrete surface is able to absorb the water compared to impervious concrete surface.

TABLE 2: COST COMPARISON OF NORMAL CONCRETE OF M20 GRADE AND PERVIOUS CONCRETE

CONCLUSIONS

The following conclusion comes through the study of the pervious concrete pavement in rural areas becomes more suitable to meet the rural area requirement such as to reduce the storm water runoff, to increase the ground water level, to eliminate the costly storm water management practices. From this we conclude that there is a considerable saving in amount about 29 Rs / m3 or 193 Rs / m2 or 18 Rs / feet2 for construction of 1m *1m* 0.15m size pavement.

Pervious concrete is the relatively new concrete for the pavement construction in rural areas having cost benefits and pervious concrete extensively used worldwide because of their environmental benefits, hydraulic and durability properties.