Fibrillated polypropylene micro fibers are usually used in concrete to control cracking due to plastic shrinkage and drying shrinkage. They also reduce the permeability of concrete and thus reduce bleeding of water.

FIBERCRETE – WF (Waved Macro Fiber) from Kalyani Polymers

FIBERCRETE is the latest innovation in polymer extrusion products developed by KALYANI POLYMERS PVT LTD, based in the south of Bangalore engaged in the manufacture of niche polymer products which have been exporting replacements for the Indian market. The company has always maintained the highest quality standards, in terms of Products, Service, and Delivery. There are several types of FIBERCRETE products available. In this article, we have focused on FIBERCRETE – WF (Waved Macro Fiber).

FIBERCRETE WF is a Waved Macro Fiber for concrete reinforcement that complies with ASTMC 1116, IRC: SP: 46 – 2013, MORTH, Standard Specification for Fiber Reinforced Concrete and Shotcrete etc, and is specifically designed to help mitigate the formation of shrinkage cracking in concrete.

Primary Applications of FIBERCRETE – WF (Waved Macro Fiber)

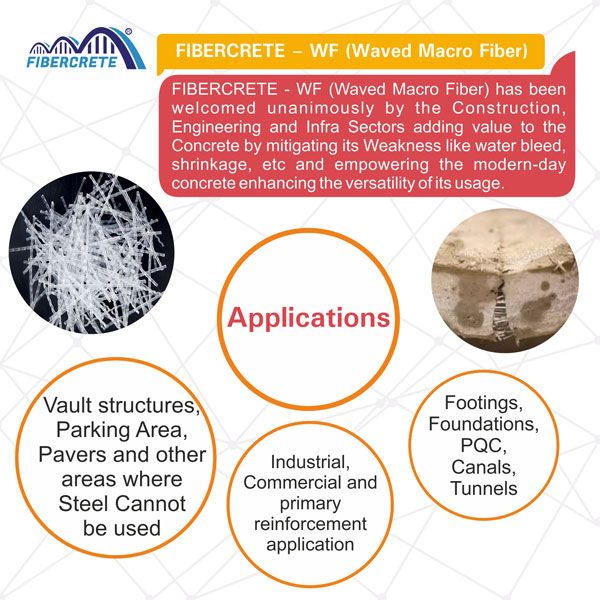

FIBERCRETE – WF (Waved Macro Fiber) has been welcomed unanimously by the Construction, Engineering and Infra Sectors adding value to the Concrete by mitigating its Weakness like water bleed, shrinkage, etc and empowering the modern-day concrete enhancing the versatility of its usage. Some of its application are;

- Industrial, Commercial and primary reinforcement application

- Footings, Foundations, PQC, Canals, Tunnels

- Vault structures, Parking Area, Pavers and other areas where Steel Cannot be used

Benefits of FIBERCRETE – WF (Waved Macro Fiber)

FIBERCRETE – WF (Waved Macro Fiber) offers more resistance to cracking and it is lighter than traditional concrete. It can sustain strain-hardening up to several percent strain, resulting in a material ductility of at least two orders of magnitude higher when compared to normal concrete. It also exhibits crack control behavior. Some of its benefits are given below;

- Controls and mitigates plastic shrinkage cracking

- The waveform for Engineered cross-linking in concrete

- Provides three-dimensional reinforcement against micro-cracking

- Used along with FIBERCRETE FE for Steel substitution

- Reduction of in-place cost versus wire mesh for temperature/shrinkage crack control

- Easily added to the concrete mixture at any time before mixing

- Cost-Effective Alternative to Steel Reinforcement.