Aging industrial buildings form the backbone of manufacturing, logistics, and heavy engineering operations across the world. Many of these facilities were constructed decades ago, designed for load conditions, materials, and operational requirements that differ significantly from today’s demands. Over time, continuous usage, environmental exposure, and operational modifications can lead to structural distress – posing safety risks, operational downtime, and costly repairs if left unaddressed. Diagnosing structural distress early is therefore essential for extending the service life of industrial buildings and ensuring safe working environments.

Common Causes of Structural Distress in Industrial Buildings

- Material Aging and Deterioration

Over time, construction materials naturally degrade. Concrete may lose strength due to carbonation, chloride ingress, alkali-aggregate reaction, or poor initial workmanship. Reinforcement corrosion can cause cracking, spalling, and reduction in load-bearing capacity. - Corrosion of Reinforcement Steel

Exposure to moisture, chemicals, or saline environments can corrode embedded steel bars. Corrosion expands the steel, leading to cracking and delamination of concrete cover. - Change in Building Usage

Older industrial structures may not have been designed for modern production demands. Increased floor loads, installation of heavy machinery, mezzanine additions, or high-density storage systems can overstress structural components. - Dynamic and Vibration Loads

Operation of heavy equipment, cranes, turbines, or generators introduces dynamic forces and vibrations that can weaken beams, slabs, and connections over time. - Environmental Exposure

Industrial buildings in coastal, chemical-processing, or high-humidity zones are prone to corrosion, sulphate attack, and chemical deterioration of concrete and steel. - Foundation and Soil Issues

Differential settlement, soil erosion, inadequate compaction, or poor drainage can lead to cracks, tilting, and misalignment of structural elements. - Water Ingress and Poor Drainage

Leaking roofs, blocked drains, or poor waterproofing can allow water penetration, accelerating corrosion and material degradation. - Design or Construction Deficiencies

Inadequate structural design, substandard materials, lack of quality control, or deviations from approved drawings can cause premature structural distress. - Lack of Maintenance

Delayed repairs, ignored minor cracks, and absence of regular structural audits can allow small defects to develop into serious structural problems.

Visual Indicators of Structural Distress

- Crack Patterns and Width

Cracks are the most common visible sign of distress. Hairline shrinkage cracks may be non-structural, but wide cracks, diagonal cracks in columns or shear walls, and horizontal cracks near reinforcement levels may indicate serious load or shear issues. - Spalling of Concrete

Flaking or breaking off of concrete cover often exposes reinforcement bars. This usually results from corrosion, freeze-thaw cycles, or poor concrete quality. - Rust Stains and Exposed Reinforcement

Brown or reddish stains on concrete surfaces signal corrosion of embedded steel. If reinforcement is visible, it suggests advanced deterioration and reduced structural capacity. - Deflection or Sagging

Noticeable bending or sagging of beams, slabs, or roof members indicates overstressing, long-term creep, or weakening of structural components. - Uneven or Cracked Floors

Differential settlement or foundation movement can cause floor cracking, uneven surfaces, or tilting of structural frames. - Misaligned Doors, Windows, or Crane Rails

Difficulty in operating doors, shutters, or overhead cranes may indicate frame distortion or foundation settlement. - Excessive Vibrations

Unusual or amplified vibrations during machinery operation can suggest inadequate stiffness, structural fatigue, or loosened connections. - Water Leakage and Damp Patches

Persistent moisture marks, dampness, or efflorescence can accelerate material deterioration and corrosion.

These visual indicators serve as the first step in identifying structural problems and help determine whether detailed structural assessment and testing are required.

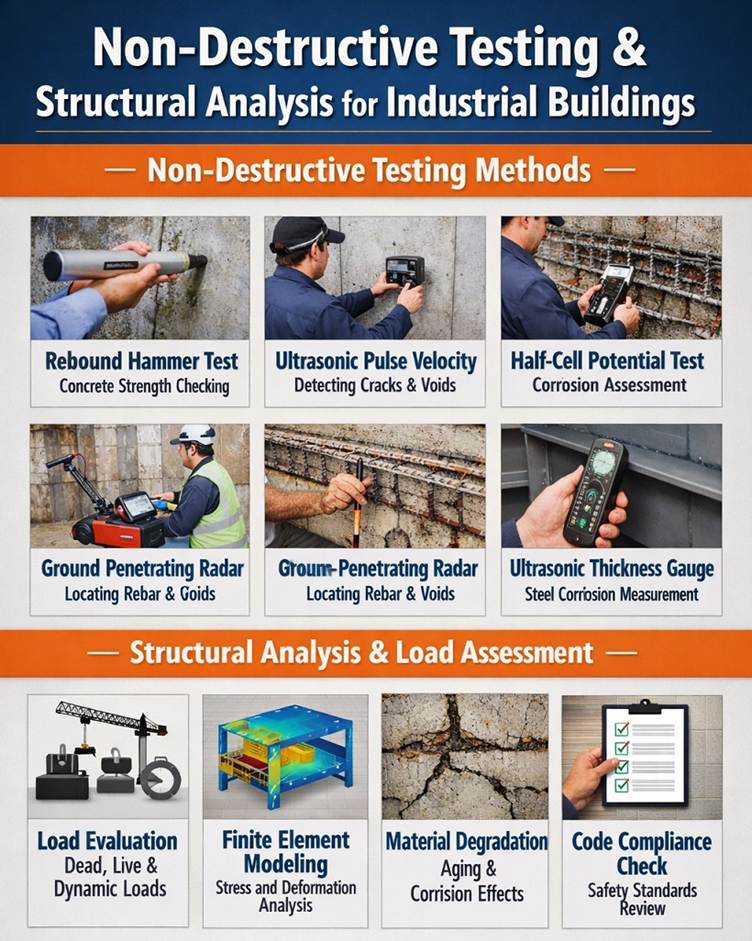

Non-Destructive Testing (NDT) and Evaluation Methods

- Rebound Hammer Test

Also known as the Schmidt hammer test, this method assesses surface hardness to estimate the compressive strength of concrete. It helps identify variations in concrete quality across structural elements. - Ultrasonic Pulse Velocity (UPV) Test

UPV measures the speed of ultrasonic waves passing through concrete. It is used to evaluate uniformity, detect internal cracks or voids, and assess overall concrete quality. - Half-Cell Potential Test

This electrochemical technique determines the probability of corrosion in embedded reinforcement by measuring electrical potential differences on the concrete surface. - Ground-Penetrating Radar (GPR)

GPR uses electromagnetic waves to locate reinforcement bars, identify voids, detect delamination, and determine slab thickness without damaging the structure. - Cover Meter Survey

Cover meters measure the depth and positioning of reinforcement bars within concrete, helping assess durability and corrosion risk. - Ultrasonic Thickness Measurement (Steel Structures)

For steel members, ultrasonic gauges measure remaining thickness to evaluate corrosion loss and structural weakening. - Vibration Analysis

Monitoring structural vibration characteristics helps detect changes in stiffness, fatigue damage, and performance under dynamic loads.

Structural Analysis and Load Assessment

- Load Evaluation

Engineers assess dead loads, live loads, dynamic equipment loads, crane loads, and environmental forces such as wind and seismic activity. - Assessment of Usage Changes

Modern machinery, mezzanine additions, or increased storage loads are evaluated against the original design capacity. - Material Degradation Consideration

Reduction in concrete strength, steel section loss due to corrosion, and fatigue effects are incorporated into structural calculations. - Advanced Structural Modeling

Finite element modeling and structural software tools simulate real-life behavior, including cracking, load redistribution, and stiffness reduction. - Code Compliance Check

The structure’s residual capacity is compared with current design standards and safety margins.

Organizations such as the International Federation for Structural Concrete encourage best practices in structural design and assessment, promoting innovative and performance-based approaches that complement national and international building codes.

Role of Maintenance History and Documentation

Historical data plays a vital role in diagnosing distress. Original drawings, design calculations, and construction records provide insight into material specifications and load assumptions. Maintenance logs reveal recurring issues, past repairs, or exposure to aggressive chemicals.

Poorly executed repairs can sometimes accelerate deterioration rather than solve the problem. Understanding what interventions were previously carried out helps engineers avoid repeating ineffective solutions and design more durable rehabilitation strategies.

Importance of Early Diagnosis and Remedial Planning

Early diagnosis of structural distress can significantly reduce repair costs and prevent catastrophic failures. Once distress is diagnosed, remedial measures may include structural strengthening, corrosion protection systems, crack repair using high-performance adhesives, or load redistribution. Advanced repair materials and bonding solutions, commonly used in industrial rehabilitation, play a crucial role in restoring structural integrity and performance.

Conclusion

Diagnosing structural distress in aging industrial buildings is a multidisciplinary process that blends visual assessment, scientific testing, structural analysis, and historical review. As industrial demands continue to evolve, many existing structures operate beyond their original design intent. Proactive diagnosis not only ensures safety and compliance but also enables informed decision-making for repair, strengthening, or adaptive reuse. By identifying problems early and addressing root causes, industries can safeguard their infrastructure, minimize downtime, and extend the functional life of critical assets in a cost-effective and sustainable manner.