Steel buildings first gained popularity in the early 20th century. Their use became more widespread during World War II and significantly expanded after the war when steel became more available. Steel buildings have been widely accepted, in part due to cost efficiency. The range of application has expanded with improved materials, products and design capabilities with the availability of computer aided design software.

Effectivity

Steel provides several advantages over other building materials.

- Steel is structurally sound and manufactured to strict specifications and tolerances.

- Any excess material is 100% recyclable.

- Steel does not easily warp, buckle, twist or bend, and is therefore easy to modify and offers design flexibility. Steel is also easy to install.

- Steel is cost effective and rarely fluctuates in price.

- Steel allows for improved quality of construction and less maintenance, while offering improved safety and resistance.

- With the propagation of mold and mildew in residential buildings, using steel minimizes these infestations. Mold needs moist, porous material to grow. Steel studs do not have those problems.

Given its advantage, professionals across the globe have experimented and innovated steel system. Discussed below are 10 of the best Innovative Steel Structures across the globe.

Denver’s historic Union Station

Denver’s historic Union Station is a Beaux Arts masterpiece located on the edge of the city’s central business district. SOM was commissioned to expand and transform this station into a major regional transportation hub. To do so, the firm converted 20 acres of former rail yards into an urban transit district that orchestrates light rail, commuter and intercity rail, bicycle and bus routes, and pedestrian pathways into an intuitive intermodal hub.

The focal point is the open-air Train Hall, which was conceived as an efficient and formally expressive means of sheltering multiple railway tracks. Its primary structural system comprises 11 steel “arch trusses” spanning nearly 180 feet, clad in tensioned PTFE fabric. In profile, the canopy rises 70 feet at either end and descends in a dynamic sweep to 22 feet at the center, a gesture that allows the structure to protect the passenger platforms below while providing views of the historic station.

The primary structural system for the Train Hall consists of eleven steel arch-trusses that support a tensioned PTFE fabric. These trusses span nearly 180 feet from a single large-diameter pin connection atop 18-foot-tall arched column supports. Each truss is stabilized by bracing struts. At the center of the Train Hall, the arch-trusses are replaced by cantilevered trusses, opening the canopy to the sky. In profile, the canopy rises 70 feet at either end and descends in a dynamic sweep to 22 feet at the center—a gesture that protects the passenger platforms below, while providing views of the historic station.

Circuit of the Americas Austin

The main architectural language of the facility evokes the precision, dynamism and performance-driven design of racecars. It is also visually stimulating, incorporating banners, billboards, and bold graphics. The architects bring their innovative approach to the structural systems: rather than being concealed behind a building’s façade they are articulated and become significant parts of the design. An architectural theme recurring throughout the site is the use of red steel tubes. The tubes cascade down the side of the Observation Tower to form a canopy for the Amphitheater stage and also frame the Main Grandstand. Evocative of sports cars and movement, this element ties the structures together creating a consistent visual experience.

The front center section with fixed seating and premium views of the stage are occupied by nine rows of box seats. The floor seating area gives the venue the flexibility to host a variety of events with options for an additional 1,528 temporary seats, banquet tables, or standing room areas. The stage itself is located at the base of the observation tower whose red steel tubes start at the top of the 251’ tall tower, spill down and spread out to form a canopy over the stage. The canopy protects performers from the elements and acts as the stage’s hanging grid to support stage lighting and speaker arrays.

Minnesota Fallen Firefighters Memorial

The memorial, located on the State Capitol grounds in Saint Paul, honors the sacrifice of Minnesota firefighters killed in the line of duty. It houses the Minnesota Firefighter Memorial Statue, previously on display at Minneapolis-Saint Paul International Airport.

The basic design requirement was that the site needed to be a living memorial—in its materiality, organization and pattern of use—and the state desired a place to honor its fallen fire fighters while providing a place for contemplating the nature of the fire service. The entire construction period was five months from contract award to final completion (from May to September 2012).

Approaching the monument, the ground rises to present visitors with a cast stone-faced wall inscribed with names of fire departments from throughout the state. A large steel monolith hovers above the focal point of the site where the statue stands, forming a pavilion to mediate between the monumental scale of the Capitol grounds and the life‐scale of the statue. A field of several light steel columns supports the weight of the monolith above, and names of the fallen are inscribed on the columns. Visitors move in the shadow of the monolith through the multitude of columns to encounter the statue, bathed in light from a mirrored void in the monolith above. Outside the pavilion a bench provides a comfortable place for reflection.

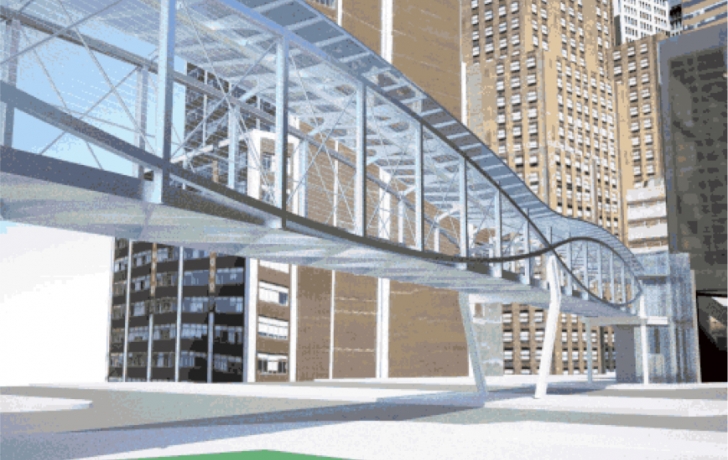

Steel-and-Glass Bridge

The pedestrian bridge links Columbus’s new Hilton Columbus Downtown hotel to the adjacent Greater Columbus Convention Center across High Street, the main thoroughfare through downtown Columbus.

The design consists of a 105-foot-long enclosed glass walkway supported by a single overhead steel tube and suspended ribs.

The entire enclosure of the bridge-floors and walls-is primarily glass. The result is a sense of physical and material lightness and visual transparency that is meant to stand out against the external, heavy-truss pedestrian bridges throughout Columbus. The unitized module of the 138-ton bridge was fabricated and shipped as small components that were then assembled and glazed on site prior to lifting the entire structure into place.

All building services, including air, water and lighting, are delivered through the overhead 48-in. steel tube or discretely within the glass walkway, maximizing the height of the interior space.

Pomona College Campus

The new 35,000-sq.-ft Studio Art Hall building replaces the century-old Rembrandt Hall, which housed Pomona College’s art program. Because the art department not only caters to art majors but also the entire student population, the college needed a space that would influence and captivate anyone who steps through its doors.

The layout is designed to inspire interaction, discussion and socialization while moving through the studios and public areas. The monumental staircase draws visitors into the space and provides an informal seating area to meet or socialize. With sweeping views of the San Gabriel Mountains, Studio Art Hall reflects its environment with an arching roof that appears to float above the building, mimicking the ebb and flow of the surrounding peaks. To create an undulating shape, most of the steel used in the roof’s framing was set at 45-degree angles with respect to the column grids. The curvature in one direction was developed by straight lines of beams at a constant elevation within the same line; in the perpendicular direction, the curved geometry was achieved by faceted beam lines. The result is a steel diagrid with sawn-lumber joists spanning between the beams to support the roofing system.

Built to LEED Gold standards, the $29-million design-assist project was designed with a green, minimalist approach by remaining open and airy with free flowing spaces and external hallways. The central courtyard is open to the sky, providing ample lighting and yet another connection to nature and the elements. Six sloped roof skylights with vents allow natural lighting and airflow throughout the studios.

Caesars Entertainment Corp

The $375 million conference center will carry a LEED silver-rating and features the world’s two largest pillarless ballrooms, anticipated opening before the end of March 2020. “CAESARS FORUM is one step closer to offering this one of a kind-option in the meetings and conventions industry. CAESARS FORUM will be the first facility of this size built on one level and is equivalent in size to twenty-seven tennis courts or three ice hockey rinks. It will also feature FORUM Plaza, the first 100,000 square-foot dedicated outdoor meeting and event space in Las Vegas.

Construction Fast Facts

- Over 7,500 pieces of Steel

- 10,000 tons of Steel

- 143,500 bolts

- More than 300,000 total construction hours

- 26,718 cubic yards of concrete

- Ten roof trusses: each 315 ft. long, shipped in three pieces

- Topping off beam was fabricated in Utah

- Typically raised with a pine tree and flag

- The first topping off with a tree dates back to 700 AD in Scandinavia

- The tree signifies, growth and health, the flag shows patriotism

Westgate Bridge

One of the most significant bridges in Australia is the Westgate Bridge over the Yarra River in Melbourne, which links the Western Suburbs of Melbourne and the southern parts of Victoria to its capital Melbourne. This bridge is a steel box girder cable stayed bridge which has a main river span of 336 m and has a total length of more than 2500 metres. This bridge collapsed during construction in October 1970, which resulted in a Royal Commission. This and a number of other notable collapses of box girder bridges in the UK and Germany also resulted in many important rules being developed by the Merrison Committee in the United Kingdom. In 2006, the Victorian government approved plans to refurbish the bridge. Some of the significant factors included strengthening the box girders whilst maintaining traffic flow over the entire work period. These works were completed in June 2011 and included significant work on the box girder. Much of the work involved the use of blind bolting techniques to increase plate stiffener thicknesses, thereby reducing the stress range operating in the boxes and subsequently the fatigue life of the structure.

Grosvenor Place

The innovative use of structural steel in this building included quite a few firsts in Australia. The building involved the use of high strength cold formed profiled steel sheets for the decking with a yield stress of 550 MPa (N/mm2). The beams which span approximately 16 metres from the reinforced concrete core to perimeter frame were designed for serviceability as semicontinuous, with a semi-rigid joint assumed between the beam and core. The columns in the lower levels of the buildings are quite unique and involve three perimeter columns being grouped at the ground level in a single column, with the key objective being the savings in space made for car parking in the basement. This involved the use of high strength quenched and tempered structural steel of yield stress of 690 MPa (N/mm2) being used for encased sections in this zone.

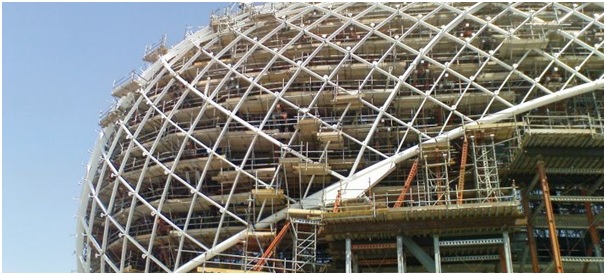

Yas Hotel

Designed using specially developed 3D software, the heavy-duty Megashor system was used to support 911 node points required for the installation of a landmark steel ladder and glass paneled shroud structure covering The Yas Hotel. When RMD Kwikform Middle East was awarded the contract to support a new 217-metre grid-shell shroud – an expanse of sweeping, curvilinear forms constructed of steel and 5,096 pivoting diamond-shaped glass panels – the business took on one of the most innovative and exciting structures in the world. For primary contractor Al Futtaim Carillion, working for developer ALDAR Properties, the requirement for a formwork and falsework based temporary works system that could safely support no fewer than 911 different node points throughout the grid-shell shroud design was essential to the project delivery. For RMD Kwikform, the design and practical execution of the formwork and falsework temporary works support were the two most challenging elements to the project.

The Solar Ark

The Solar Ark’s design was inspired by the vision of an ark embarking on a journey to the 21st century. This idea led to the Solar Ark’s size and overall symbolic shape of being an example of producing clean energy. In total, the construction area for the Solar Ark is 3294.48 m2 reinforced concrete was used for the base of the construction. From one end to the other, the total length of the Solar Ark is 315 metres. The ark is 31.6 metres tall from the centre of the structure. There are 5,046 solar panels in total. Twelve single-crystal silicon solar cell modules per unit were assembled on the ground, and 470 units were lifted up and attached to the main body of the Solar Ark.

The weight of the actual body of the ark (pillars being excluded) is 3,000 metric tonnes and is constructed from structural steel. This construction material helps give the impression of the solar ark being suspended in the air. Each column is 2 metres in diameter and 31 meters in length and the Solar Ark is 315 metres long. The entire Solar Ark chassis is supported by four “G-Columns” which are custom built pillars by Kubota and in total, these pillars weigh approximately 5,000 tonnes. These high-quality pillars are homogeneous, the result of the seamless method of construction that utilizes centrifugal force. Due to the Solar Ark’s sturdy building materials, the Ark is able to resist winds of up to 34 meters/second and level 7 earthquakes on the Japanese scale.

The ark is surrounded by 5-meter high water fountains and two ponds, each having their own cascade. The entrance to the Solar Ark has solar wings which are composed of HIT solar cells that generate electricity on the topside and underside while also functioning as awnings that allow sunlight to filter through. Between the individual solar panels, there are, in total, 75,000 red, green, and blue computer controlled LEDs which are activated at night to produce images and words across the ark.

Conclusion

The innovation is an ongoing process and designers across the world are really innovating with steel structure.

Info and image- som.com, archdaily.com, AISC.ORG, Paintsqaure, cee.ntu.edu.sg, pinterest, latimes, engineering news record, flickr, Rmd Kwikform, inhabitat, tribecatrib.com