Lifting and rigging tools used in the lifting, hoisting, securing, lashing, towing, and anchoring of loads so they can be moved safely and efficiently. Projects that need to move heavy loads typically employ a system or assembly of rigging components to secure the load to a crane, hoist, or platform. Rigging tools includes chains, wire ropes, slings, connections, fittings, end attachments, and other equipment. In comparison, lifting hardware is a subset of rigging hardware that is designed for the vertical movement of loads.

Types of lifting and rigging tools

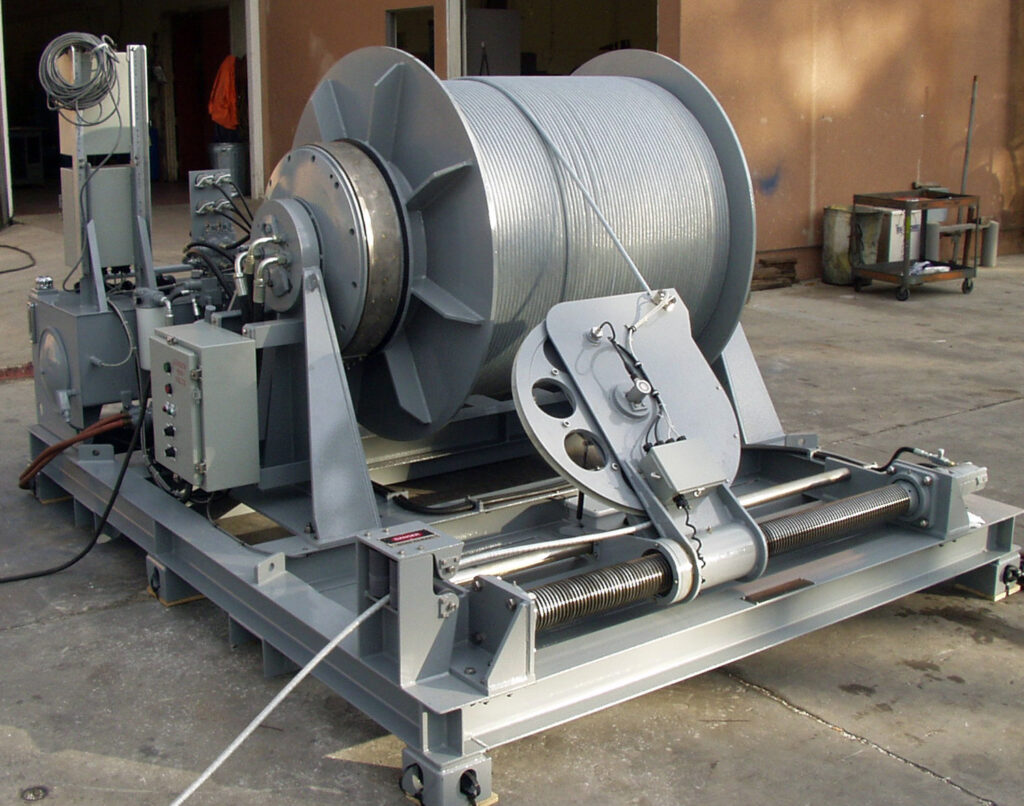

Winch

A winch is a mechanical device that is used to pull in or let out (wind out) or otherwise adjust the tension of a rope or wire rope. In its simplest form, it consists of a spool (or drum) attached to a hand crank. Winches are the basis of such machines as tow trucks, steam shovels and elevators. More complex designs have gear assemblies and can be powered by electric, hydraulic, pneumatic or internal combustion drives. It might include a solenoid brake and/or a mechanical brake or ratchet and pawl which prevents it unwinding unless the pawl is retracted.

Sling

When it comes to overhead lifting of heavy loads, choosing the right type of sling is critical for both ease of use and safety. Slings are extensively used in safe lifting and moving of a variety of loads including pipes, building material, or even boxcars. These are invaluable tools for loading certain kinds of non-palletized cargo. If it cannot be lifted on a pallet or driven up ramps, it has to be hoisted using a crane, forklift, or other means. That’s where lifting slings and shackles come in. You are going to need both to lift that cargo from the bottom.

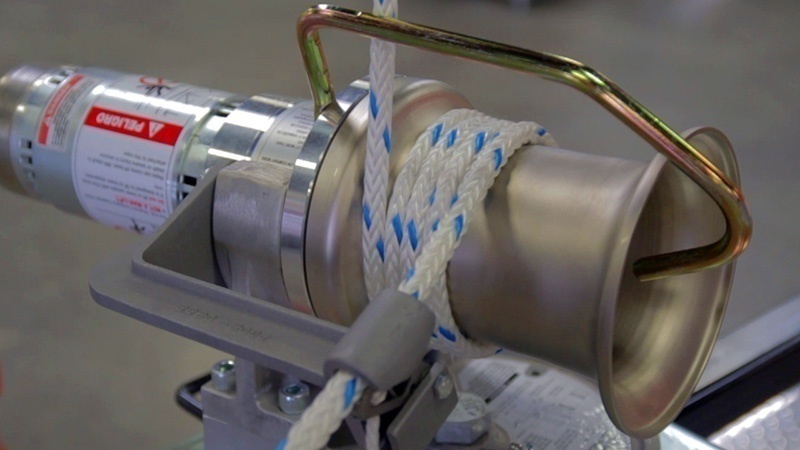

Capstan hoist tool

Capstan hoisting devices have been used to lift or move heavy loads for centuries. The latest models make back-breaking work fast, easy and productive. Safety is the most important consideration in work. A shortcut or misapplication of equipment can cause damage, injury or worse

Double Braid Rope

Double braided rope has a braided core surrounded by a braided sheath. The inner and outer braids are generally designed to share the load equally with very low elongation. Double braid rope remains round under tension, imparts no rotational force when loaded, and has a soft hand.

Pulley blocks

Pulley blocks are grooved wheels on a fixed axle onto which passes a continuous length of wire rope. A pulley block is a classic example of as a mechanical device that changes the direction or magnitude of a force by virtue of the principle of ‘mechanical advantage’.Pulley blocks are generally employed as a set of two or more sheaves, with rope or cable threaded between them through grooves. The entire assemblage – block, the ropes or cable and the load to be lifted – comprises the pulley system. As the number of pulleys increases, so does the mechanical advantage.

Shackle

A shackle is a u-shaped, load-bearing connecting device designed to be used with a removable pin. Shackles can be used in a number of different rigging and load securement applications to connect different types of lifting slings, chain, or rope to an object or to each other. Latest models are also manufactured with steel chain designs where a high level of corrosion resistance is require.

Swivel hooks

A swivel is a type of rigging hardware that is used to position a load and/or swivel under the weight of a load. These are used for load positioning and/or swivelling under load to accommodate load movement and twisting. They’re essentially made up of two end fittings connected at the centre. They’re particularly useful in situations where a load may sway or spin.

Turnbuckles

A turnbuckle, stretching screw or bottlescrew is a device for adjusting the tension or length of ropes, cables, tie rods, and other tensioning systems. It normally consists of two threaded eye bolts, one screwed into each end of a small metal frame, one with a left-hand thread and the other with a right-hand thread. The tension can be adjusted by rotating the frame, which causes both eye bolts to be screwed in or out simultaneously, without twisting the eye bolts or attached cable.

Pulling Rope

Electrical contractor, tower rigging, and other pullers rejoice, you have found your source for the highest quality pulling ropes in the business. There are high quality pulling ropes in sizes ranging from 3/8 all the way to 1″ in diameter.

Conclusion

Discussed above are different types of lifting and rigging toolsAll rigging and lifting tools should be inspected before use to ensure that it is undamaged. The Occupational Safety and Health Administration (OSHA) states that it should be “inspected prior to use on each shift and as necessary during its use to ensure that it is safe.You can also Protect PDF Documents with PDF4Sure.