The concrete deck is prone to water ingress, water may drip through cracks or other surfaces, which may inevitably decay the surrounding area. In the long run, this will be quite costly to fix. In order to avoid this, and to keep your deck in the best shape, waterproofing is key. Horizontal surfaces exposed to the weather can be difficult to waterproof. Inadequate slope can create areas of standing water. In colder climates, freeze/thaw cycles impose additional challenges. Frequently, the coating also has to stand up to foot traffic as well.

The most common cause of a ceiling leak is a failure in the waterproof membrane or screed in the floor slab of the upper floor apartment. The failure may be because of natural deterioration of the waterproof membrane, material damage or faulty construction/installation of the membrane. Whatever the cause, the membrane loses its waterproof properties and is no longer able to prevent water from penetrating the porous concrete floor slab and seeping into the lower part of that slab.

Waterproofing your deck also allows the concrete to be protected from natural foot traffic and the elements. When you waterproof your deck, a special coating is added to the concrete that will help make it impenetrable as well as making it easy to maintain. One good way to know that you need to resurface and waterproof your concrete deck is if there are multiple cracks in the deck. Often, resurfacing your deck might not be as expensive as you might think. Since the actual foundation does not need to be fixed, the top level of the deck is the only thing that is being changed. Once the floor has been resurfaced, it will not have any cracks or other signs of wear.

Advantages of concrete deck waterproofing membranes

The modern membranes provide a wide array of advantages and products are now available with multiple advantages, narrowed down are some of the common advantages of these products.

Preparation of waterproofing membranes in Concrete decks

- All surfaces to be waterproofed must be firm, clean, dry, sound and smooth. All grease, oil, wax, curing compounds, loose material, paint and any other contaminants must be removed, masonry surfaces must be pointed flush and surface defects repaired. New concrete must be cured for a minimum 28 days.

- External corners to be waterproofed must be bevelled to ensure a smooth transition of membrane from vertical to horizontal surfaces.

Concrete Deck waterproofing membranes

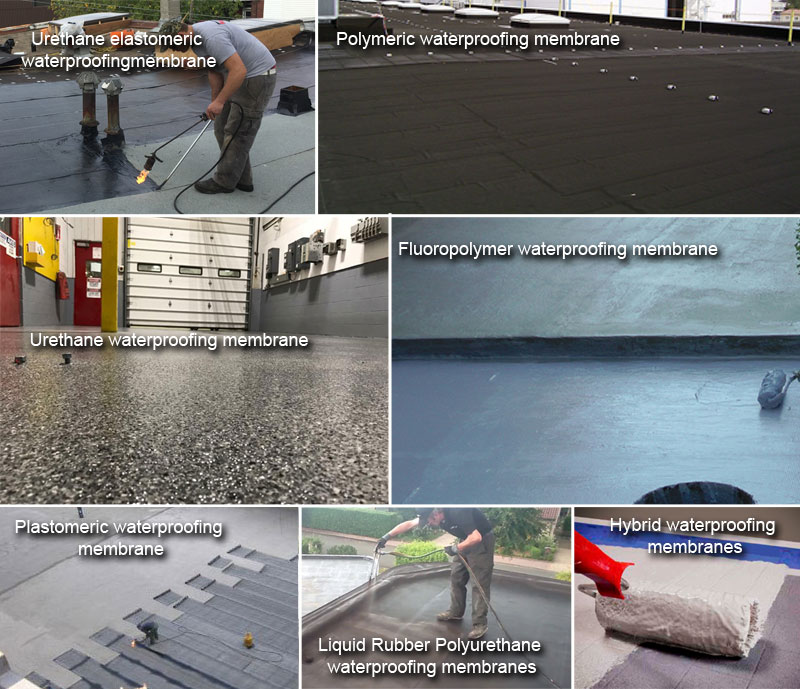

Urethane elastomeric waterproofing membrane

Urethane elastomeric membrane is both flexible and durable. This chemical resistant, moisture cured, polyurethane system is designed to expand and contract with normal structural movements. It has an aesthetically pleasing monolithic surface that will not soften in heat or become brittle in cold. With the use of a catalyst the urethane decking system can be accelerated to a two-day application. The coating system is a waterproofing system that can be used on a wide range of applications. Installed and maintained properly, this system will ensure years of waterproofing protection.

Polymeric waterproofing membrane

It is shrink-resistant, heavy-duty, polypropylene woven carrier fabric. The two components are laminated together under strictly controlled production procedures. It provides an excellent waterproofing membrane for bridges, parking decks or other vehicular traffic structures to be overlaid with an asphalt concrete wearing course. It is ideal for repair, maintenance, or new construction applications.

Plastomeric waterproofing membrane

These membranes are manufactured in advanced – under controlled conditions by saturating and coating a robust reinforcement of synthetic non woven polyester carrier with a homogenous thermoplastic bituminous blend of distilled asphalt, modified with selected polymer and inert fillers which gives the membrane its excellent properties of resistance to ageing, facilitates the ease of application and adhesion and accommodates structural movements. These are designed as a cap-layer in exposed membrane systems. They are ideal for flat or sloped roofs, tiles on terraces & for improved aesthetics.

Urethane waterproofing membrane

It is a single component, a moisture-cured elastomeric urethane waterproofing system designed for pedestrian traffic. It is a monolithic system, designed to waterproof concrete and plywood surfaces by excluding moisture penetration during low-temperature exposure as well as high temperature, high humidity thermal cycling. This waterproofing system has excellent adhesion, impact, and abrasion resistance while exhibiting superior flexibility and weather resistance.

New Halogen-Free Parylene waterproofing membrane

New Halogen-Free Parylene coating offers manufacturers the same host of beneficial properties that they have come to expect from the Parylene family, but with improved barrier properties over traditional halogen-free variants. It is applied through a vapor deposition process that results in an ultra-thin, uniform, pinhole-free conformal coating. The thin film forms at a molecular level to fully encapsulate components and devices, offering complete protection and increased reliability of intricate, complex electronic devices.

Fluoropolymer waterproofing membrane

A fluoropolymer is a polymer that is based in fluorocarbon and has strong carbon-fluoride bonds. fluoropolymer is a chemical compound that contains many strong carbon-fluoride bonds. The fluorine in a fluoropolymer is electrically negative, which gives it the property of not bonding easily with other materials. That’s what makes a fluoropolymer non-stick. Fluoropolymer coatings have excellent non-stick properties and reduce friction and resist corrosion. They withstand very high temperatures, as well. Fluoropolymers are insulators, meaning they do not conduct electricity. They do not absorb water, either.

Liquid Rubber Polyurethane waterproofing membranes

It is a monolithic, fully-bonded, liquid-based coating suitable for many waterproofing and roofing applications. The coating cures to form a rubber-like elastomeric waterproof membrane and may be applied over many substrates, including asphalt, bitumen and concrete. This is to apply, ultra-low VOC coating can be used to protect decks, docks, outdoor walkways, floors and much more. Given the cured membrane’s superior strength, waterproof properties and high adhesion to most substrates.

Hybrid waterproofing membranes

Modern hybris coating includes polymer-modified, polyurethane-asphalt hybrid coating cures to form a tough and highly-elastic membrane and provides durable and seamless waterproofing protection for concrete substrates. When completely dry and fully bonded to the substrate, the coating forms an impervious continuous barrier to eliminate the migration of water between the membrane and substrate. It is ideal for application on concrete decks, especially where surface profiles and the presence of services provided detailing difficulties for the use of pre-formed membranes.