The sustainability concept encompasses the integration of social, environmental, and economic considerations to meet present needs without compromising the ability of future generations to meet their own needs. Various models have been developed to assess and implement sustainability across different domains, including infrastructure systems.

This article explores the development of sustainability concepts and models, briefly touching on six types of models commonly used to assess the sustainability of infrastructure systems. These models encompass social, environmental, economic, energy, entropy, values, norms, and influence orientation.

Building on this foundation, the article recognizes precast concrete as a sustainable construction practice due to its technological superiority over conventional methods. This leads to various sustainability benefits, including extended life cycles, reduced resource consumption, temporary construction, efficient land use, shorter project times, controlled release of particulate matter, improved social standards, and increased availability of environmentally friendly, intelligent, and secure job opportunities.

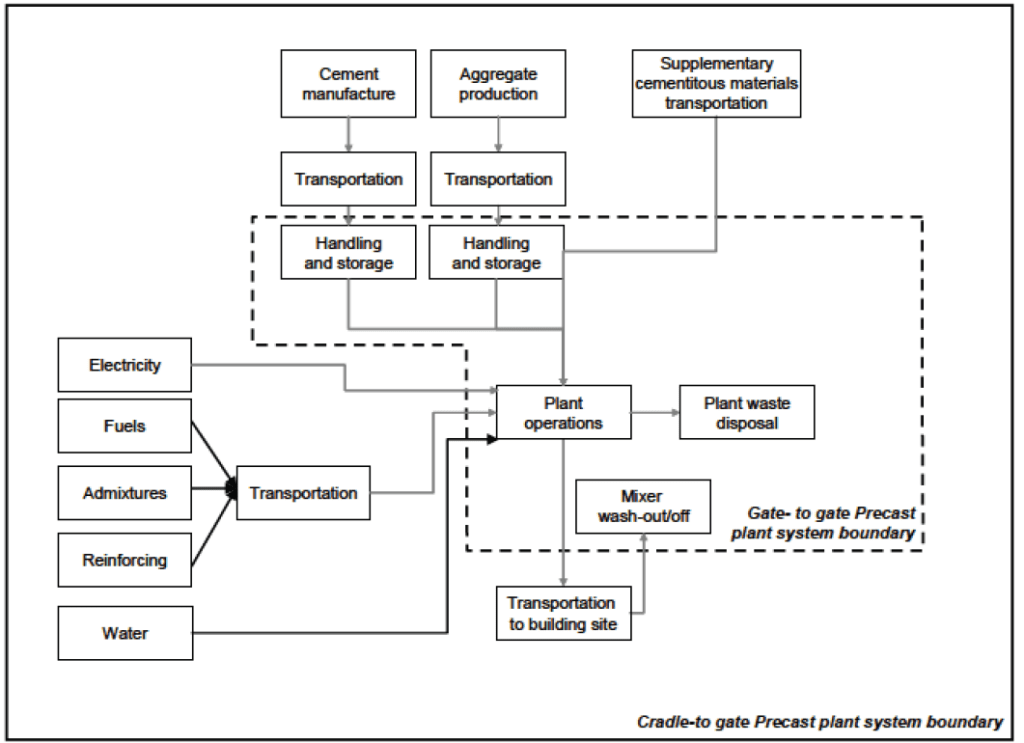

The article illustrates the cradle-to-gate life cycle concept for precast products in building systems through an international literature review. It explains the distinction between the boundaries of precast manufacturing systems and infrastructure systems, highlighting differences in the stages of life cycle assessment.

Emphasizing that agencies responsible for sustainability conversions have defined scopes and performance limits, the article notes that the sustainability contribution of precast industries can be predominantly assessed through their factory practices rather than on-site practices. Consequently, the article focuses on factory precast practices, exemplified by the case study of FUJI Silvertech Concrete Pvt. Ltd, a leading precast industry in India. It highlights various reasons driving such organizations to adopt sustainable practices.

Additionally, the article identifies 100 indicators of sustainable approaches in precast manufacturing organizations, broadly classified into 11 sets. These sets encompass declarations and ownerships, responsible purchasing, environmental management systems, quality management systems, occupational health and safety management systems, environmental product declarations, environmental impact of operations, social sustainability aspects, human resource management aspects, economic aspects, and organizational values.

The article focuses on the key role that sustainability organizations and professional associations can play as a way forward to precast concrete sustainability initiatives.

- The concept of sustainability and its parameters

Sustainability, as a concept in infrastructure systems, has been expressed in various philosophies. In literature, three major categories of sustainability frameworks can be identified. These are linkage based, impact based or influence based.

1.1. Linkage framework: social forces on environment and economy

A Linkages-based framework captures relationships between the causal factors, impacts and corrective actions related to achieving sustainability. Linkage based models include the PSR Model (Pressure – State – Response), the DPSIR Model (Drivers – Pressures – State – Impact – Responses) and the Environment –Economy linkages model.

The PSR model was an attempt to identify globally relevant indicators and provide useful measurement methods for arriving at a decision. The model establishes societal action as sources of pressure on the state of the environment which calls for the response required mainly by human efforts (political and societal decisions, measures and policies) to counterbalance the adverse effects of the action.

The PSR model was soon modified to include the drivers and the impact thus giving rise to the more popularly used DPSIR Model (Drivers – Pressures – State – Impact –Responses). The DPSIR widely adopted by the European Environmental Agency traces causal linkage beginning with the ‘driving forces’ (economic sectors, human activities) through ‘pressures’ (emissions, waste) to ‘states’ (physical, chemical and biological) and ‘impacts’ on ecosystems, human health and functions, eventually leading to political ‘responses’ (prioritization, target setting, indicators). However, it may be noted that the reasons underlying the pressures are not identified which makes it difficult to bring out the controlling factors for the way of response and secondly, the motivations behind responses are not identified.

The Environment – Economy linkages are addressed by almost all countries now and the concept has been revised by ORTEE as a “criterion-influences-actions-measures” system wherein a selected criterion, such as carbon dioxide emissions, for example, can be deconstructed into a number of influences e.g., persons exposed.

1.2. Impacts framework: Energy, Entropy, Values and Norms

An Impacts-based framework focuses on the nature and extent of various kinds of impacts that collectively determine the sustainability of a system without necessarily capturing causal factors and corrective actions. The most common impacts-based framework is the three dimensional framework of indicators based on economic, environmental, and social impacts. Many models use this tripartite framework to evaluate sustainability of different types of civil infrastructure. These include the Pearce and Vanegas (2002) model and the Rijsberman and van de Ven (2000) model which are also found relevant for study and application to infrastructure systems.

The Pearce and Vanegas (2002) model was developed for measuring technological sustainability for building infrastructure. It derives its concepts from thermodynamic fundamentals assuming the earth to be a constrained but open system where there is no net loss of energy however there is entropy defined by the “degradation of energy”. Realizing that the consumption of energy leads to entropy and the adverse impact is offset mainly by the efforts of the natural ecosystem, the sustainability objectives are defined in thermodynamic sense as “minimizing consumption of matter and energy” and “minimizing negative impacts to natural ecosystems”. The concepts are extended by Pearce and Vanegas for the operation and management of built systems and to identify and compare system performance. The model also considers the stakeholder satisfaction, resource base impact and ecosystem impact. This may be considered more relevant for the decision making process than other optimization models; and methods can be used to optimize energy consumption or reduction in pollution or similar parameters, this model can incorporate various dimensions of every alternative which when plotted on an octant of sustainability can help take a decision from the stakeholders’ perspective.

The Rijsberman and van de Ven (2000) model addresses sustainability in qualitative as well as quantitative terms thus explaining four basic approaches to sustainability that are influenced by people, norms, values, and the environment. The quantitative approach is based on norms, and the qualitative approach is based on values. These approaches are: (i) Capacity approach: norms and environment (ii) Ratio centric approach: norms and people (iii) Sociocentric approach: values and people (iv) Eco centric approach: values and environment.

1.3. Agency framework: Influence circle of agency

An Influence-oriented framework is developed keeping in mind the role and level of influence of the responsible agency or organization conducting the study. Thus the various actions and/or activities of the organizations that influence progress towards sustainability define the scope and objective of the framework.

It was proposed by Jeon and Amekudzi (2005) to have a “Unified framework” for developing indicator systems for infrastructure system sustainability, in which all three types of framework approaches may be combined.

1.4. Other parameters: inputs, outputs, education and policy landscapes

Here again it must be noted that many initiatives fail to address the education related to sustainability. This is an inherent element for bringing awareness among various stakeholders so that they can take necessary actions to bring about this desired change. Although it may not be measurable, it has a value that should also be captured. Secondly, it might be useful to have a balance of input-oriented and output-oriented parameters. Sometimes performance or output or impact based models do not give importance to inputs or causal parameters, maybe because it is outside the responsibility scope of the agency; however, identifications of causes of critical impacts could be used for policy formulation and provide direction towards effective action.

- Sustainability benefits of precast concrete as a construction technology

The practice of casting the concrete at a factory or site other than site of construction in moulds or form systems commonly addressed as precast concrete construction is gaining importance as several benefits of the practice are identified. Many of these benefits, especially in the case of factory precast production, pertain directly or indirectly to sustainability.

Precast concrete construction as a sustainable practice can be identified by the many benefits in terms of resource saving, carbon footprint, time saving and improvement of social standards as compared to conventional or cast in situ construction. Some of the factors that illustrate factually the sustainability benefits of this technology are illustrated below:

(a) Life of the concrete:

Being manufactured in a controlled and systematic condition at the factory, the quality and durability of precast concrete exceeds that of the conventional cast in situ construction. This is reflected in the longevity of the precast concrete construction. There are, therefore, longer life cycle resulting in lower life cycle costs and lower maintenance costs that make precast more sustainable.

(b) Saving in raw material resources:

Precast concrete construction is often done using higher grade of concrete and high strength reinforcing material. This leads to a slender design thus saving material consumption. Moreover, in a factory precast production, the wastage is minimal as compared to site and materials such as water are also used in controlled manner.

(c) Saving in temporary structures/formwork

Further, the formwork reuses are much more than the formwork reuse at site. This lowers the cost of temporary structures required at site.

(d) Legal and environmental norms

Factories manufacturing precast are subjected to various industrial compliances including Pollution Control Board norms, Central Ground water authority norms and other norms that pertain to green cover, safe use, reuse and release of materials in various processes. This puts a check and control on the impact of the industrial process on the environment.

(e) Social standards upliftment

There are similar norms for legal and statutory requirements for safety and health thus checking social impact. Being an industry, socio economic development is inevitable. Corporate social responsibility features in the industry bring additional human perspectives of sustainability.

(f) Release of particulate matter in the air

Cement, sand, flyash and similar fine size raw materials that go into the concrete construction are much more controlled in the industry through PPEs, dust collectors, and the process of addition as compared to its uncontrolled release in the air on site operations. These particles are responsible for dermatological and respiratory health hazards and controlling their release definitely helps in occupational health and safety for workers associated with the operations as well as passersby.

(g) Greener smarter jobs and job security

The installation onsite processes of precast concrete products are much safer and smarter jobs and also called green jobs for construction workforce on site as compared to cast in situ construction. Construction industry in general still provides temporary employment for project duration to workers and professionals. Whereas in an industry that manufactures precast concrete, a longer commitment and security of jobs is available.

(h) Construction project time

By far the main goals of construction being project time, resource efficiency and material-manpower-machinery consumption. In all these ways precast concrete offers a superior advantage over cast in situ construction. The saving in project time when calculated on present worth definitely converts into a profitable margin. The consumption as well as efficiency of the 3 Ms is much lower for precast as opposed to cast in situ.

(i) Saving in space

Land is required for a longer period for storage of raw materials and construction processes in a cast in situ method. The value of land is ever increasing and is also critical when construction is to be carried out in urban areas. The precast production requires land spaces in form of stockyard at factories which can be remotely situated and requires space at the site for storage of precast elements which can be controlled by matching dispatch and installation operation speed.

- The concept of cradle to gate life cycle assessment

Life cycle assessments for measurement of environmental impact are common paradigms of sustainability. Life cycle assessment stages in precast concrete construction can involve (a) Extraction of natural resources (b) Manufacturing (c) Transportation (d) Product use (e ) Recycling (f) Disposal. A life cycle assessment framework requires a goal and scope definition, inventory analysis, impact assessment and the interpretation of these impacts. These frameworks have direct implications on product development, strategic planning, public policy making, marketing etc.

The environmental impacts can be assessed in the form of global warming, acidification, respiratory effects, solid waste, eutrophication, water use, resource depletion, ozone depletion, renewable and non-renewable energy use etc.

As discussed prior, the scope and influence of the agency is crucial to define when it comes to sustainability contribution or impact assessment owing to a certain agency. Life cycle assessments are generally carried out by cradle to grave analysis. These can be modified for the precast systems to cradle to gate analysis. However, the C-G analysis can have a scope that limits itself to the plant system or encompasses the entire life of the precast infrastructure. Illustrations below explain the difference in these scopes:

- Drivers of sustainability in precast concrete manufacturing organizations

Sustainability in precast concrete product factories can be driven by many factors. Some of these factors are illustrated below with examples citing some reference to the factories of FUJI Silvertech Concrete Pvt. Ltd. which is India’s one of the largest precast concrete manufacturers of the time dispatching precast drains, box culverts, retaining walls, noise barriers etc. pan-India.

4.1. Leadership Commitment and Vision:

Leadership commitment to standards, abidance of legal and statutory norms, the stand on environmental protection and safe and healthy work culture are inherent and addictive factors that drive the fabric of an organization. The commitment is demonstrated by the policies and awareness of these policies among all persons working in the industry.

4.2. Organizational culture and values:

The infrastructure as noticed by green cover, clean and hygienic water and sanitation facilities, cleanliness or the behaviour of the persons with respect to work sometimes illustrates the culture of the organization towards sustainability. Human values towards environment, towards discipline and quality and in the sincerity of performing process operations are the strength on which an organization process becomes sustainable.

4.3. Factory internal standards:

Industrial operations have their own standards which by far are not matched in performance or efficiency by site operations. Many manufacturing units have got International system standards like ISO 9001, ISO 14001, ISO 45001 which through its process of standards documentation, measurement and monitoring, internal and external auditing and performance reviews naturally keep a system up and fine. There are many sustainability benefits in ISO standards but these are discussed in brief in the next section.

4.4. Legal and statutory requirements:

Factories are forced to abide by Factories Act, Pollution Control Board, ground water authorities, Noise pollution rules, waste management rules and almost 50 odd legal acts which enforce sustainability in terms of social, economic and environmental impact.

4.5. Business interest:

Sustainability is also promoted as a business interest when customers, small and big now require industries to do a vendor registration process insisting on social and environmental practices prevailing in the organization. Moreover, in many projects the tender specifying the manufacturer qualification is such that these sustainability parameters need to be maintained in the industry to qualify for key projects.

4.6. Incentives from external parties:

The government authorities like Ministry of Road Transport and Highways, Ministry of housing and urban affairs and the Ministry of railways have promoted sustainable technologies like precast concrete construction in their many circulars. State centres like IndextB in Gujarat that promote industry investment opportunities, also bring in incentive schemes for sustainability initiatives such as incentive for ISO Certifications, Zero effect zero defect (ZED) certifications.

4.7. Employee education and motivation:

As also identified as a lacuna, a natural driver of sustainability is in the persona of every human being trying to make the world a more sustainable place. However, these needs to be initiated and fired by education, awareness programs and trainings such as tool box talks on safety culture or training on responsible and sustainable procurement, or business ethics.

- Indicators of sustainability in precast concrete factory

Based on the study of various models, propositions by international standards like ISO and councils like Concrete Sustainability Council, close to 100 different indicators were identified for precast concrete factories. A list of these indicators is provided below:

5.1. Declarations:

- Declaration to abide by legalities

- Universal Declaration of human rights

- Suppliers adherence to moral and ethical conduct

- Timely salaries and minimum wages

- Demonstrate traceability

5.2. Responsible and Sustainable Purchasing:

- Sustainable Purchasing Policy

- Supplier assessment of social and environmental aspect

- Suppliers performance evidence

- Responsible and sustainable sourcing training

- Promoting responsible sourcing by public communication

- Responsible sourcing as a procurement criterion

- Random material check can be traced

5.3. Environmental Management System:

- Existence of an Environmental Management System

- Certification of EMS

- Environmental Policy

- Environmental aspects impact

- Environmental obligations

- Environmental objectives

- Evaluation of compliance

- Environmental audits

- Continual Improvement

5.4. Quality Management System:

- Existence of a Documented Quality Management System

- Certification of QMS

- Quality Policy

- Risk and Opportunity

- Customer Focus

- Quality Compliance

- Dealing with nonconformity

- Quality audits

- Rejection and resource wastage

- Continual Improvement

5.5. Occupational Health and Safety Management System:

- Existence of a Health and Safety Management System

- Certification of OHS

- OHS Policy

- Hazard Identification and Risk Assessment

- Operations to eliminate hazards and risks

- Workplace monitoring

- Work Permits

- Emergency Preparedness and response

- Incident Investigations

- Safety and Tool Box Trainings

- Safety audits

5.6. Life cycle perspectives and Environmental Product Declarations

- Environmental Product Declaration

- Life cycle assessments

- Release of EPD

- Responsible use of Land

- Control of vibrations and noise

- Separate and appropriate storage of hazardous waste

- Monitoring of GHG Emissions

- Verification of GHG by external party

- CO2 Reduction target

- Awareness on energy consumption

5.7. Environment and Operations

- Green cover

- Dust Collector systems in Silos

- Dust suppression measures

- Assessment of water scarcity

- Monitoring and reporting of water consumption

- Target on water use

- Quantity of used water

- Quality of discharged water

- Water recycling and reuse possibilities

- Use of secondary materials

- Environmental impact of transport of materials

- Dispatch related data and transporter information

- Assessment to minimize impact

5.8. Sustainable Society

- Engagement with local community

- Initiatives and programs for social aspects of community

- Noise/vibration reduction to local community

- Safety measures that risk to passerby is minimum

- Safety measures to minimize risk of transport accidents

- Ground water sharing with nearby villages

- Health and safety of persons in factory

- Health checkups

- OHS Policy and Awareness

- Recognizing social factors in OHS System

- First aid, hospital tie ups, medical treatments

- Access to clean drinking water and sanitation

5.9. Caring for human resources

- Employment impact due to organizational change

- Mental health and anxiety

- Employee records availability and accessibility

- Appraisal procedure

- Profile for every job

- Access to skills development and training

- Opportunities for career advancement

- Preventive medical examination

- Reasonable working hours

5.10. Economic Growth for Sustainability

- Needs of local economy

- Risk assessments of operations

- Policy or code of Business ethics

- Suspected cases of corruption

- Ethical behavior training

- Property rights – physical and intellectual

- Innovation and patents

- Feedback from employees

- Feedback from suppliers

- Feedback and complaints from customers

5.11. People Values for Sustainability

- Discipline

- No Compromises

- Honoring Commitments

- Long Lasting relationships

- Way forward and possible initiatives for precast concrete sustainability practices

Life cycle assessments or cradle to grave assessments for typical sustainability measurements exist. But very little knowhow or literature on the approach of cradle to gate assessment for precast production is available.

Environmental product declarations require expensive life cycle consultants and very selected program operators for this certification are available. This knowhow and pool needs to be expanded. EPD may have become common for the cement industry but it has not yet entered the precast concrete industry as a practice.

Good precast concrete manufacturing industries have gone an extra mile by means of technology and factory set ups to provide sustainable practices. There needs to be a policy landscape for differentiating these industries from those who do not give the same contribution. Then and then only, an incentive or motivation towards sustainable practices in industry will gain importance. A framework and rating of precast concrete factory processes helps in goal setting and benchmarking towards sustainable operations.

Finally, many international councils such as the Concrete Sustainability Council have parametric assessment for awarding sustainability certification. Similar factory processes can be initiated by organizations on a national platform.

About the author

The author is currently the research and development head at FUJI Silvertech Concrete Pvt. Ltd., an Indo-Japanese precast solution provider in India for about 3 years. She graduated with civil engineering from BVM Engineering College, Gujarat and with structural engineering major from University of Illinois, Urbana Champaign. She was associated as a structural engineer at Welsch Engineering, Chicago for about 5 years where she developed design and drawings for precast residential and university buildings in and around Illinois, USA. After which she was associated as a faculty at CEPT University for about 14 years, Ahmedabad where she was program chair for structural engineering design and infrastructure engineering management program. She holds a PhD from Pandit Deendayal Petroleum University in sustainable infrastructure management. In her current profile, she is instrumental in product development of precast structures and establishing quality, environmental and occupational health safety management systems. She is also a certified product development professional and a certified lead auditor for ISO 9001. She also works towards life cycle assessment and carbon footprint analysis of precast products and other sustainability certifications.

References

- CPCI-TRB#12-01: Life cycle assessment of precast concrete commercial buildings

- Life Cycle Assessment for Sustainable Design of Precast Concrete Commercial Buildings in Canada, Marceau et al

- Addressing Sustainability in Transportation Systems: Definitions, Indicators, and Metrics, Jeon and Amekudzi

- Life Cycle Assessment of Precast Concrete Belowground Infrastructure Products – Executive Summary

- Quality management systems—Requirements

- Environmental Management Systems—Requirements

- Occupational Health and Safety Management System – Requirements

- ISO: Environmental labels and declarations — Type III environmental declarations — Principles and procedures

- ISO : Sustainability in buildings and civil engineering works — Core rules for environmental product declarations of construction products and services

- Concrete Sustainability Council (csc.eco)