The process of designing high-rise buildings have changed over the past years. In the most recent years it is not unusual to model full three-dimensional finite element models of the buildings. The advances in structure design of High Rise Building started in the 20th Century while its formation was laid during 1880’s with use of cast iron as a building material which was lighter and also better than masonry. Gradually, elevators cemented the way for high rise buildings. In the past few decades, high-rise buildings have received a renewed interest in many city business locations, where land is scarce, as per their economics, sustainability, and other benefits. Taller and taller towers are being built everywhere in the world. However, the increased frequency of multihazard disasters makes it challenging to balance between a resilient and sustainable construction. Accordingly, it is essential to understand the behavior of such structures under multihazard loadings, in order to apply such knowledge to design.

The designing component in high rise buildings

IS 16700 : 2017 defines Tall building as a building whose heights are above 50 Mtr but less than or equal to 250 Mtr. The code has classified Tall Building as:

- Structural wall system

- Moment frame System

- Moment frame, structural wall system

- Structural wall

- Flat slab floor

- Structural wall – framed tube system

- Framed tube system Tube in the tube system.

- Multiple tube system.

- Hybrid system

- Any of above with additional framing system- ex. Outrigger trusses, belt truss.

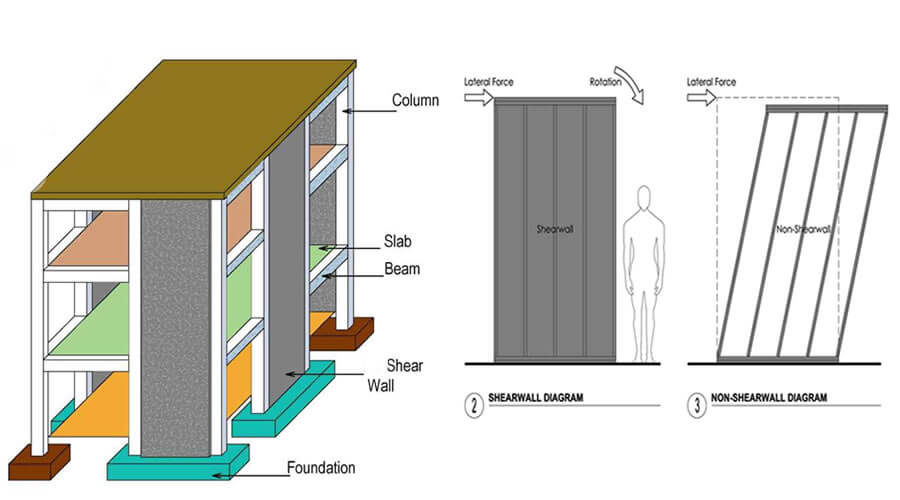

The design in High Rise Building were largely of three unique elements:

In recent high-rise buildings, there are many cases where large spans are required to gain spacial freedom on typical floors and wide atria to allow continuity with the external spaces on the lower floors. In order to achieve these spaces, it is necessary to provide high strength in the structural members that constitute the building structure, particularly the columns. It is possible to avoid excessively large volume columns by using appropriate combinations of high strength materials.

- New design of bold lines, rectangles where heavy structures made up of steel define power and prestige.

- The amalgamation of interior spaces and exterior facade as a one unit.

- Use of steel and concrete as structural and members

Buildings are usually subjected to static loads, such as occupants’ weight, equipment, furniture, and the weight of the structure. However, two important environmental loads that are different in nature may attack our buildings once or twice during their lifetime. The nature of the two loads is totally different from the static load, and even if they could be expressed as equivalent static loads, tall buildings and flexible structures may amplify the internal loads resulting in additional inertia loads which can alarm the serviceability and the comfort concern of people in a building or even lead to a complete collapse. When it comes to dynamics and load-structure interaction, the inherently low damping in buildings is a key parameter that can be used to control the behavior of a structure under such dynamic loads. In addition, a building’s orientation change can result in wind response/load reduction. High-rise buildings are an increasingly common sight because they provide a high ratio of rentable floor space per unit area of land, in addition to other factors, such as architectural and energy perspectives. Tall buildings or “skyscrapers” can be artificially lighted and the energy requirements can be covered by renewable energy or another electricity generation of lower greenhouse gas emissions. Heating and cooling of skyscrapers can be efficient, because of centralized HVAC systems, heat radiation blocking windows, and small surface area of the building. There is a Leadership in Energy and Environmental Design (LEED) certification for skyscrapers.

Dynamics of buildings greatly depends on the characteristics of the external excitation as well as the physical properties of the building in terms of generalized masses, frequencies, and damping. Wind loads are characterized by low frequencies while earthquakes usually contain higher frequency load components.

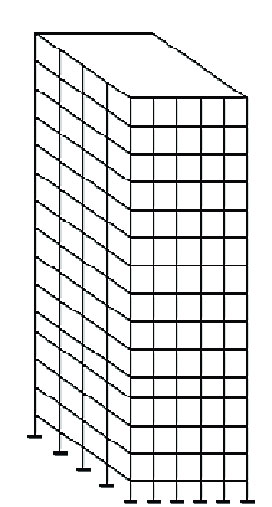

Stabilization of high rise buildings design

Knowledge, technology and construction materials are constantly evolving and so is the strife for constructing higher buildings. However, it does not go without some challenges and issues. First off, the vertical loads increase with the height of the building. There is also the large effect from horizontal wind-load on the building. The buildings behaviour under the lateral loading can be seen as a cantilever fixed at the ground. If the wind is assumed to have a uniform distribution the base-moment increases quadratic with the height. However, the real shape of the wind pressure is increasing with the height, which gives even greater base-moment. One of the main tasks when designing high-rise buildings is its ability to absorb the horizontal forces and to transmit the resulting moment into the foundation. One way to effectively achieve this are coupled load-bearing vertical walls. However, this will lead to tensile stresses in the concrete walls on the loaded side. In order to minimise these stresses, self-weight of slabs etc. are placed on the walls to get compressive stresses.

The higher a building is, the more important it is to consider the choice of cross sections, materials and structural systems as well as the demands on functionality. Factors that need to be considered are deflections and accelerations from horizontal loading that mainly occurs from unexpected deflections, wind or earthquakes. Unexpected deflections may arise when imperfections in the elements occur during the manufacturing or if the foundation is uneven due to an inhomogeneous site. Any unexpected deflection causes additional lateral forces and must be considered. Horizontal loading from wind may also cause sway in the building. This since highrise buildings are susceptible for oscillation. The wind should therefore not only be seen as a static load but also as a dynamic load. To determine how the building responds to wind-loads, wind tunnel experiments are often performed. The oscillation affects the building in several ways, how the people inside perceive the sway and the maximum horizontal deflection that arises.

Concrete buildings can either be cast in-situ, composed with precast elements or a combination of both. If the building is cast in-situ it is possible to start the activities on site in an early stage. Preparation for scaffolding and moulding can start as soon as the contract is assigned to the contractor and the design of the building starts. This is not possible when constructing precast elements as all decisions regarding dimensions, shapes and so forth have to be taken long before the activities on site can start. When using precast elements it is of importance to industrialise the manufacturing. This implies manufacturing in covered factories, use of automatic tools and thoroughly planning the production process. There are some important differences regarding cast in-situ and precast buildings. When a building is cast in-situ the elements are created in moulds on site and are constantly checked to have the correct height. But when a building is constructed with precast elements the elements are created in a factory where the factory worker is fully dependent on the drawing. If for example a column has the wrong height on the drawing, no one will correct this in the factory and an incorrect column will be created causing problems on site.

When designing a precast building it is important to consider the connections between elements, which are part of the assembly procedure and should not interfere. Connections can be divided in wet and dry connections. The difference between these are the use of concrete or mortar. Wet connections are for example, mortar joints, cast-in-situ blocks or cast-in-situ slabs that are more fire resistant, less sensitive for tolerance criteria and more ductile than dry connections. Examples of dry connections are free supports, welded connections and cold joints which are quick to assemble.

Loads of high rise building design

The foundations of high-rise buildings support very heavy loads, but the systems developed for low-rise buildings are used, though enlarged in scale. These include concrete caisson columns bearing on rock or building on exposed rock itself. Bearing piles and floating foundations are also used.

Loads that have to be taken into consideration when designing a building are vertical loads from self-weight, imposed loads, snow loads and horizontal loads from both wind and unintended inclinations. For tall buildings, as earlier mentioned, the horizontal loading from wind is usually the design load. The vertical loads are the self-weights, finishing loads and live loads and they are transferred to the foundation through columns, load-bearing walls or towers. The live load depends on the type of usage in the building and on the standard used for designing. The higher value is often used for offices to take the variable partitioning and the greater live load in corridor areas into account. Some reduction of the live load can be made depending on the number of stories, but may never exceed 40% for any construction element.

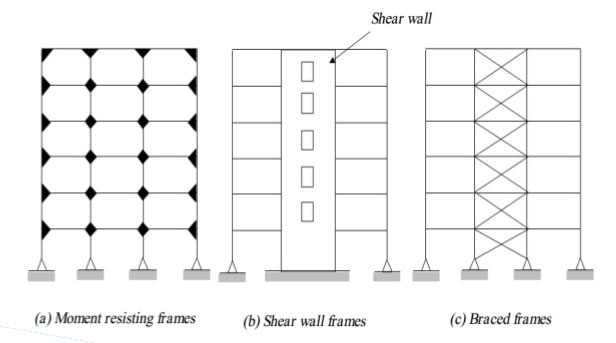

The horizontal load from wind working as a distributed load on the facade, which transfers the load to the slabs. The slabs are working as diaphragms and provide the lateral transfer of the shear load to the vertical elements and also as a stability unit for the compression flange of the steel beam beneath. The shear forces in the diaphragms occur mainly in the concrete because of its in-plane stiffness. The horizontal loads are transferred from the slabs to the beams through welded studs. Depending on how the slabs are connected to the facade, the stress distributions in the slabs will vary. For example, the slabs can be connected directly to the facade, which gives a distributed load. The facade can also be connected to columns which will provide point loads instead. The load distribution depends on the stiffness of the elements as stiffer units attract more load than weaker. When designing vertical walls in a building both shear and bending deformation may occur. For low robust walls the bending is negligible and for tall slender structures shear is negligible. Considering the entire building the shear wall becomes tall and slender, however, the walls in each plane are low and robust making it susceptible to both shear and bending. For a tall building the deformation shapes from bending and shear.

Structural systems of high rise building design

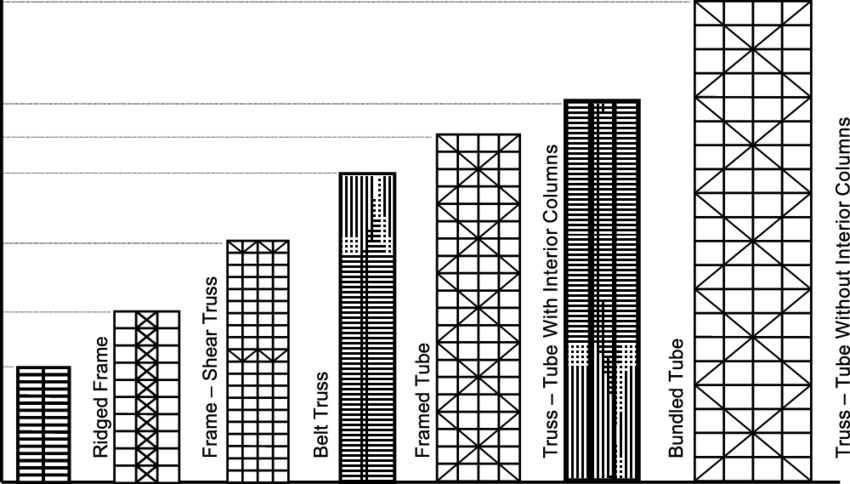

A building needs to be stabilised for horizontal load and to achieve this, several different structural systems can be chosen. All of the different systems have evolved from the traditional rigidly jointed structural frame. The fundamental design for all these structural systems have been to place as much of the load-carrying material as possible around the buildings external fringe to maximise its flexural rigidity. For all structural systems, advantage can be taken by locating the main vertical members and, with the compressive stresses from self weight, suppress the lateral load tensile stresses. This to avoid net tension in the vertical members and uplift in the foundations. For some structural systems it is necessary to have self-weight at the outer vertical members in order to achieve this.

Framed tube structures

For framed tube structures the lateral resistance is given by very stiff moment resisting frames that form a tube around the perimeter of the building. The frames consists of closely spaced columns, 2–4 meters between centres, connected by girders. The tube carries all the lateral load and the self-weight is distributed between the outer tube and the interior columns or walls. For the lateral loading the perimeter frames aligned in the load direction acts as webs of the tube cantilever and those perpendicular to the load direction acts as flanges. The tube structure is suitable for both steel and reinforced concrete buildings and have been used in the range of 40–100 stories. Framed tube systems have been the most significant modern development in high-rise structural forms and is easily constructed and usable for great heights. For the aesthetics of the tube structure the enthusiasm is mixed, some like the logic of the clearly expressed structure while others criticise the grid-like facade as small windowed and repetitious.

Bundled tube

The bundled tube structure consists of four parallel rigid frames in each orthogonal direction, interconnected to form nine bundled tubes. The principle is the same as for the single tube structure where the frames in the horizontal load direction acts as webs and the perpendicular frames acts as flanges. By introducing the internal webs the shear lag is drastically reduced and as a result the stresses in the columns are more evenly distributed and their contribution to the lateral stiffness is more significant. This allows for the columns to be spaced further apart and to be less striking.

Tube in tube

What differentiates the tube in tube concept from other structural systems is that an outer framed tube (hull), is working together with an internal tube (core), usually elevator shafts and stairs, to resist both the lateral and vertical loading. This provides increased lateral stiffness and can be seen as the shear and flexural components of a wall-frame structure.

Diagonalised – and rigid frame

In braced frames the lateral resistance is given by diagonal members that, together with the girders, form a web of vertical trusses, where the columns acting as chords. Bracing systems are highly efficient at resisting lateral loads. This due to the horizontal shear in the building is resisted by the horizontal components resulting in tensile and compressive actions in the web members. The bracing system is an almost steel exclusive system since the diagonals are inevitably subjected to tension for one or the other direction of the lateral loading. Braced systems are able to produce a very stiff lateral structure for a minimum of additional material which makes it economically efficient for any height. The major disadvantage with diagonal bracing is that it is limiting the internal planning and the location of windows. Furthermore, the connections to the diagonals are expensive to fabricate and erect.

Outrigger system

The outrigger system is an efficient structural form that consists of a central core with outriggers, connecting the core to the outer columns. The central core contains either braced frames or shear walls. When the building is loaded laterally the vertical plane rotations are resisted by the outriggers through tension in the windward columns and compression in the leeward columns. This is augmenting the lateral stiffness of the building and reducing the lateral deflections as well as the moments in the core. In addition, the outriggers join the columns and make the building behave almost as a composite cantilever. Even the perimeter columns, those not directly connected to the outriggers, can be used to increase the lateral resistance of the building by connecting all the perimeter columns with a horizontal girder around the building’s facade. Multilevel outrigger systems can provide up to five times the moment resistance of a single outrigger system. Outrigger systems have been used for buildings up to 70 stories but the concept should hold for even higher buildings.

Hybrid structure

Hybrid structures are often used for non-prismatic structures where two or more of the basic structures described earlier are used in the same building. This concept can be used for either direct combination of, for example, a tube and an outrigger system or by adopting different systems for different parts of the building, for example a tube system on three walls and a frame on the fourth wall.

Conclusion

The dynamic effects should be considered both for serviceability and safety. When considering safety, the risks of resonance are of interest and when considering serviceability, the human response to motion are of interest. Movement in a tall building can have a wide range of human response, from anxiety to acute nausea. This can make a building undesirable and may produce difficulties renting floor area. Why it is of importance to not just consider stability issues but also consider motions. Movements in buildings are commonly generated from wind, earthquakes, machinery, nearby industrial plants and various types of transportation. It would be expensive to construct a high-rise building that could withstand all movements. That is why there are various recommendations regarding accelerations in buildings depending on the occupancy.

Info and image – byggmek.lth.se, ijitee.org, hindawi.com, bdcnetwork, researchgate, byggmek.lth.se, ijitee.org, hindawi.com, researchgate.net, s3da-design.com, theb1m.com, slideshare.com, Youtube.com, inflatable-structures.co.uk, bdcnetwork, quora.com