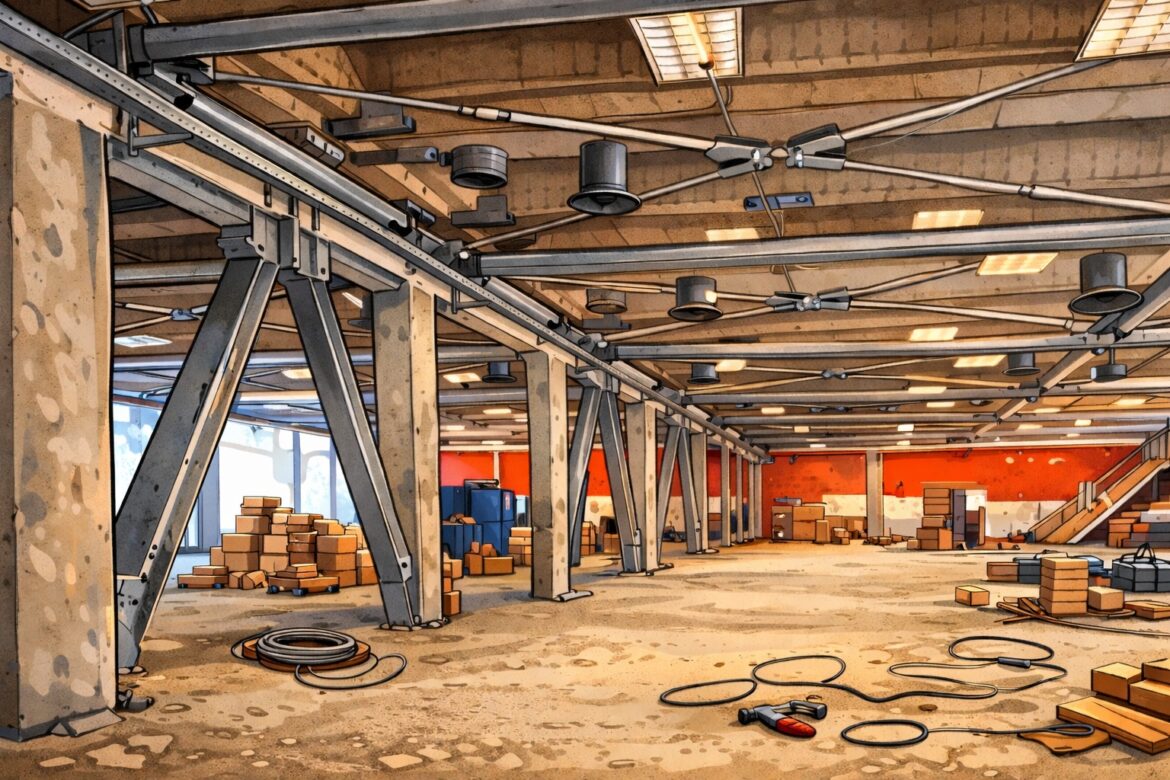

Industrial facilities face a major danger from earthquakes because they cause structural damage, equipment failure, and downtime. Many structures already constructed may not satisfy contemporary safety criteria as they were constructed under earlier seismic standards. To maintain operations and increase safety, seismic retrofitting toughens these structures.

Equipment, plumbing, and storage systems among other non-structural components also affect general performance. Good retrofit plans evaluate both non-structural and structural elements.

Importance of Seismic Retrofitting in Industrial Zones

For sustained financial continuity and uninterrupted operations, high seismic zone industrial facilities are essential. Damage from earthquakes can raise repair costs, create safety risks, and interrupt output. A reasonable way to meet new safety rules without major construction is through seismic strengthening.

Key drivers for seismic retrofitting include:

- Reducing the probability of structural damage

- Improve worker safety and emergency performance

- Protect essential machinery and process systems

- Achieve compliance with updated seismic design regulations

- Control operational losses and repair expenditures after seismic events

Common Seismic Risks in Industrial Buildings

Many industrial buildings, especially older ones or those expanded without full review, have common seismic weaknesses. Installing heavy equipment without proper assessment can increase these vulnerabilities.

Typical risk factors include:

- Insufficient lateral load-resisting systems

- Poor beam-column or foundation connections

- Structural irregularities and large open spans

- Unanchored mechanical equipment and piping

- Material deterioration or unrecorded alterations

Evaluating and Planning Seismic Retrofits

Seismic retrofitting first starts with an evaluation of the current structure. Engineers review design documents, inspect the site, and assess possible earthquake performance for both the installed equipment and the building.

The evaluation typically considers:

- Expected seismic forces based on location and soil conditions

- Structural capacity under current loading

- Interaction between structure and equipment

- Compliance gaps with current seismic codes

Common Seismic Retrofitting Methods

Retrofit methods depend on the building’s type, use, and expected seismic loads. In industrial facilities, the focus is usually on strengthening existing structural and non-structural systems rather than replacing them.

Retrofit methods include:

- Steel bracing or moment-resisting frames to improve lateral load resistance

- Beam and column strengthening using steel or composite materials

- Installation of shear walls in suitable locations

- Equipment anchorage and seismic bracing systems

- Foundation strengthening based on soil conditions and load requirements

Operational and Regulatory Considerations

Many times, industrial retrofitting occurs as the systems continue to function. Phasing building thoughtfully and arranging with maintenance timetables reduces interruption. Controlled buildings must also adhere to local and federal seismic and safety guidelines.

Key considerations include:

- Reducing production interruptions

- Maintaining worker safety during construction activities

- Compliance with local and national seismic requirements

- Maintaining accurate documentation and regulatory approvals

Practical Benefits of Seismic Retrofitting

Seismic retrofitting shields vital assets, lowers long-term risk, and strengthens industrial buildings against earthquakes. It promotes compliance with present laws, speeds recovery following earthquakes, and improves safety. By giving retrofit top priority in a wider systemic perspective, decision-makers over time enhance reliability and operational continuity.

FAQs

1. What is seismic retrofitting?

It is the strengthening of existing industrial buildings and equipment to resist earthquake forces and reduce damage.

2. Why is it necessary for industrial facilities?

Earthquakes can damage structures, machinery, and utilities, causing safety risks, high repair costs, and long production shutdowns.

3. Which facilities need retrofitting?

Older buildings, facilities in seismic zones, and plants with heavy or unanchored equipment need retrofitting the most.

4. What are common seismic risks in industrial buildings?

Weak lateral systems, poor connections, large open spans, unanchored machinery, and ageing materials.

5. Are non-structural components important?

Yes. Equipment, piping, storage racks, and utilities often cause maximum damage if not properly anchored.

6. How is seismic risk assessed?

Engineers inspect the structure, review drawings, assess soil and seismic forces, and check compliance with current codes.

7. What retrofit methods are commonly used?

Steel bracing, column and beam strengthening, shear walls, equipment anchoring, and foundation strengthening.

8. Can retrofitting be done without stopping operations?

Yes. Work can be phased and planned around maintenance schedules to minimize disruption.

9. Does retrofitting help meet regulations?

Yes. It helps facilities comply with updated seismic and safety codes and reduces legal and insurance risks.

10. What are the key benefits of seismic retrofitting?

Improved safety, reduced damage, faster recovery, lower costs, and better operational continuity.