A structure may require retrofitting due to upgrading of design standards, increased safety requirements, change in its function, loads can increase or higher building standards become required and the structure must be made compliant. In such scenarios appropriate method and material is a prerequisite to regaining their structural strength. One such method is Carbon fiber wrap technology. It uses carbon fiber fabrics on the surface of the concrete to form a composite that works in coordination with concrete to strengthen the component structure and improve its mechanical performance. The method can be used on nearly any type of structural member to harden and increase structural capacity and protect against uplift, progressive collapse, and spalling.

Unlike traditional retrofit or reconstruction techniques, carbon wrap goes right over the existing substrate. This minimizes disruption during repair and saves significantly on installation time and costs. RELinforce™ by Reliance Composite Solutions comes with properties such as high tensile strength, high stiffness, high strength to weight ratio, high chemical resistance, temperature tolerance to excessive heat and low thermal expansion. It is applied in the form of a flexible fabric during installation, then saturated with a resin matrix, allowing it to harden to transform to a strong, unyielding material with a strength-to-weight ratio.

Discussed below is a case study of Princess Street Flyover in Mumbai which was retrofitted using the Reliance Carbon Fiber Reinforced Polymer – CFRP solutions. We have focused on the site requirement, retrofitting method and material used in the project. This contains a brief detailing of the site background, solution provided and the application process completed in 2020.

Retrofitting of Princess Street Flyover using Carbon Fiber Reinforced Polymer

Site Background:

A 50-year-old flyover in Mumbai was retrofitted using the Reliance Carbon Fiber Reinforced Polymer – CFRP solutions. 36 expansion joints in the flyover were replaced and the load-bearing capacity was improved using the provided CFRP Solution.

Solution Provided:

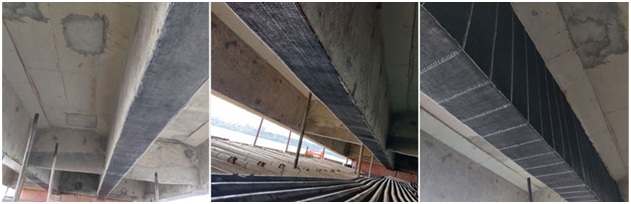

a. Application of 4 layers of carbon fiber on the bottom phase of the girder along the length of the beam.

b. Application 1 layer of carbon fiber as U wrap till 1/3rd of the length of the span from both the ends of the girder.

Timeline for Completion of Work: 18-24 Months (Including Surface Preparation to Final Wrapping process)

Materials Used:

1) RELinforce™ C Fab 600

2) RELinforce™ EP Putty

3) RELinforce™ Fab S

Application Process:

- As it was an old bridge, micro-concreting work was done and all undulations were filled using the RELinforce™ EP Putty to provide a smooth surface, ready for CFRP application.

- Reliance RELinforce™ provides a primer-less system for CFRP wrapping solution on concrete structures.

- Once surface preparation was done, RELinforce™ C Fab 600 was applied to the girders, beams and pillars with the help of RELinforce™ Fab S

- As per the site requirement,4 layers of Carbon fiber were applied along the length of the beam.

- After the application of 4 horizontal carbon fiber layers, the U Wrapping process was started. 4 layers of carbon fabric provide strength and support to the beam as well as to the structure.

- The U wrapping process provides holding support to the applied 4 layers of the carbon fabric which further improves the strength of the structure.

- Finally, the surface was painted with Epoxy & PU-based coating to avoid the environmental degradation of the Epoxy saturant as well as to give better aesthetics to the flyover.

About Relinforce™ Carbon wrap & Glass Fiber-reinforced polymer products

Relinforce™ range of Carbon wrap & Glass Fiber-reinforced polymer products are manufactured and supplied under Reliance India’s Composites Solution Division. Reliance Industries Limited is India’s largest private and one of the most profitable private sector companies and the first Indian Fortune 500 company.

Relinforce™ product range is used for structural strengthening & protection of the structural members using guidelines that conform to international standards.

These products just don’t repair degraded structures, but it makes the structures stronger even against harmful effects of seismic forces or further corrosion. There is a wide range of products combined with outstanding combinations of properties, such as low weight, immunity to corrosion, excellent mechanical strength and stiffness to tackle the issues on hand with ease.

To know more about the product, visit- www.reliancecomposites.com and contact on Petchem.Relinforce@ril.com.