Expansion joint tape is used for the sealing of high movement expansion gaps across various surfaces/substrates. It provides water tightness and is used in concrete construction for the sealing of construction joints across wall-to-base connections, pipe entry systems, sealing of openings and interface sections between existing and new concrete. PRONIL PROSEAL is a flexible sealing tape, thin and extra-tough elastic strip with considerable longitudinal and lateral extension. It is a Thermoplastic Elastomer high-performance joint and cracks sealing tape for construction joints, expansion (movement) joints and connection joints or cracks. It is a thin flexible sealing tape with extra-tough elastic strip providing considerable longitudinal and lateral extension. It is ideal for sealing and waterproofing expansion joints and over cracks subject to irregular and high movements.

Advantages of PROSEAL – Expansion Joint Tape

- Flexible, permanently elastic.

- Highly versatile.

- Good tensile properties.

- Stable form and UV-resistant.

- Heat weldable,.

- Easy to install.

- Long term resistance to bacteria.

- Non-hazardous for users.

Applications of PROSEAL – Expansion Joint Tape

- Construction joints and cracks.

- Future movements of the construction without causing damages.

- Basements.

- Tunnel construction.

- Around metal surfaces.

- Swimming pools.

- Cable and pipe penetrations.

- Sewage treatment plants.

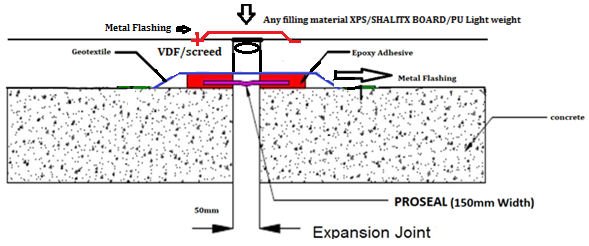

Application Methodology of PROSEAL – Expansion Joint Tape: (Horizontal Area).

Surface Preparation:

- Surfaces must be clean, sound and dry. All the broken edges should be repaired with the high strength readymade mortars and all the joint should be straight.

- Surfaces should be free from dust, oil, grease and other similar contaminants.

Mixing – EPOXY ADHESIVE:

- Premix the “A” and “B” components separately.

- Then add the “B” component to the “A” component and mix them until the mixture is uniform in colour.

- For mixing, use a low speed mechanical mixing device with a suitable mixing paddle.

Application:

- EPOXY ADHESIVE is applied to the prepared substrate on both the sides of the joint so that both sides of the PROSEAL are embedded into the

- EPOXY ADHESIVE on a width of at least 40mm. The layer thickness of EPOXY ADHESIVE should be approximately 2mm.

- The PROSEAL is then immediately embedded into the fresh EPOXY ADHESIVE and pressed using a hand roller or a similar suitable tool.

- Make sure that the PROSEAL has good contact with the EPOXY ADHESIVE everywhere.

- Then a second layer of EPOXY ADHESIVE is applied on top, so that the edges of PROSEAL are over coated on a width of minimum 40mm.

- Also apply EPOXY ADHESIVE at a width of at least 20mm, so that it covers the substrate next to the PROSEAL.

- Laying of 200-250 GSM Geotextile Membrane or any board over the TPE tape, this will protect the waterproof tape while doing the screed.

- While doing the Screed, Open the gap & maintain the gap for expansion contraction of the Joint and the Tape.

- If it is a normal foot traffic, Lay 1.25mm GI or Aluminium plate fixed with one sided screw.

- If it is a driveway, Top layer will be fixed with Aluminium or GI Chequered Plate with a Minimum thickness of 5mm to protect the entire system from the top with one sided screw.

Application Methodology of PROSEAL – Expansion Joint Tape: (Vertical Area).

Surface Preparation:

- Surfaces must be clean, sound and dry. All the broken edges should be repaired with the high strength readymade mortars and all the joint should be straight.

- Surfaces should be free from dust, oil, grease and other similar contaminants.

Mixing – EPOXY ADHESIVE:

- Premix the “A” and “B” components separately.

- Then add the “B” component to the “A” component and mix them until the mixture is uniform in colour.

- For mixing, use a low speed mechanical mixing device with a suitable mixing paddle.

Application:

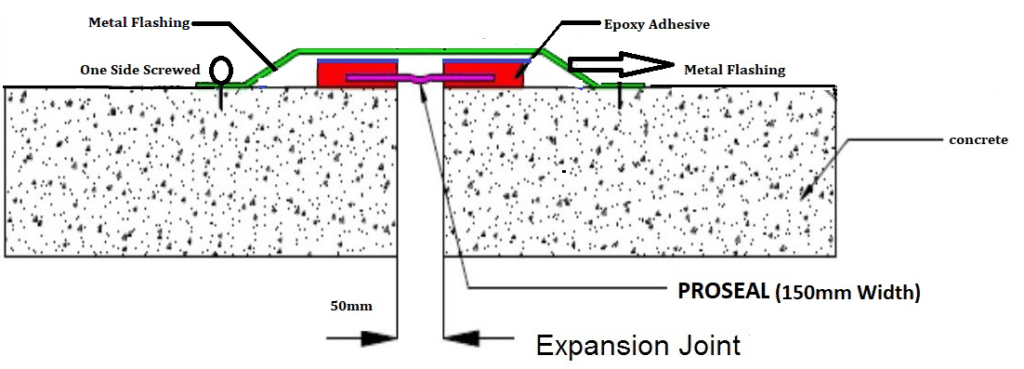

- EPOXY ADHESIVE is applied to the prepared substrate on both the sides of the joint so that both sides of the PROSEAL are embedded into the

- EPOXY ADHESIVE on a width of at least 40mm. The layer thickness of EPOXY ADHESIVE should be approximately 2mm.

- The PROSEAL is then immediately embedded into the fresh EPOXY ADHESIVE and pressed using a hand roller or a similar suitable tool.

- Make sure that the PROSEAL has good contact with the EPOXY ADHESIVE everywhere.

- Then a second layer of EPOXY ADHESIVE is applied on top, so that the edges of PROSEAL are over coated on a width of minimum 40mm.

- Also apply EPOXY ADHESIVE at a width of at least 20mm, so that it covers the substrate next to the PROSEAL.

From the ground level, up to the 7 feet of Finished floor level lay 1.2 mm GI or Aluminium Plate Fixed with both sided screws. (For Vertical Surface)

* Proseal Expansion Joint tape can be Paintable with any Acrylic/any hybrid UV resistant coating systems. (For Vertical Surface)

About PRONIL Construction Chemicals

PRONIL specializes in manufacturing high-performance Acrylic Swellable Bars, Bentonite Hydrophilic Waterstops and Expansion Joint Tapes for construction for two decades. They also have a wide range of Expansion Joint tapes and Waterproofing flexible Joint sealing tapes.

To know more about the product range, visit:- https://www.pronil.com/ or contact – +91 9489058644