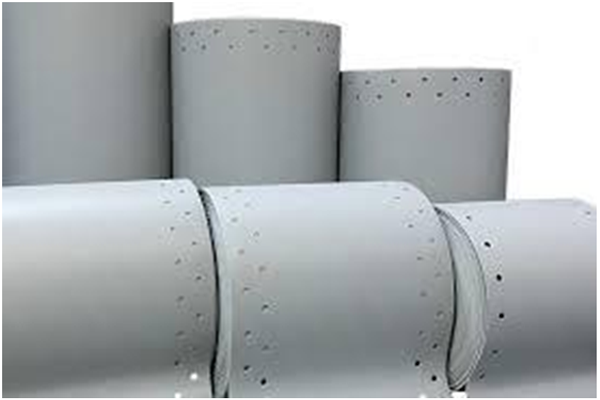

Joint sealing tape is a type of adhesive tape used to seal joints between two surfaces, such as in construction and plumbing applications. It is typically made of a flexible material, such as foam or rubber, and has an adhesive backing that allows it to stick securely to the surfaces it is sealing. It is commonly used to seal gaps and joints in building components to prevent air and water infiltration. It is also used in plumbing applications to seal joints between pipes and fittings to prevent leaks. There are many different types of joint sealing tape available, each designed for specific applications and environments. When selecting joint sealing tape, it is important to choose a tape that is compatible with the surfaces it will be applied to and the environment in which it will be used. Proper installation is also important to ensure that the tape forms a tight seal and provides effective protection against air and water infiltration. PRONIL PROSEAL is a Thermoplastic Elastomer high-performance joint and cracks sealing tape for construction joints, expansion (movement) joints and connection joints or cracks.

It is a thin flexible sealing tape with an extra-tough elastic strip providing considerable longitudinal and lateral extension. It is non-hazardous for users and provides long-term resistance against bacterization. It is ideal for sealing and waterproofing expansion joints and over cracks subject to irregular and high movements. It is very easy to install. The use of thermal welding with the PROSEAL ensures secure and watertight joints.

PRONIL PROSEAL Advantages

- Flexible, permanently elastic.

- Highly versatile.

- Good tensile properties.

- Stable form and UV-resistant.

- Heat weldable,.

- Easy to install,.

- Long term resistance to bacterizes.

- Non-hazardous for users.

Application Methodology of PROSEAL – Expansion Joint Tape: (Horizontal Area)

Surface Preparation:

- Surfaces must be clean, sound and dry. All the broken edges should be repaired with the high strength readymade mortars and all the joint should be straight.

- Surfaces should be free from dust, oil, grease and other similar contaminants.

Mixing – EPOXY ADHESIVE:

- Premix the “A” and “B” components separately.

- Then add the “B” component to the “A” component and mix them until the mixture is uniform in colour.

- For mixing, use a low speed mechanical mixing device with a suitable mixing paddle.

Application:

- POXY ADHESIVE is applied to the prepared substrate on both the sides of the joint so that both sides of the PROSEAL are embedded into the

- EPOXY ADHESIVE on a width of at least 40mm. The layer thickness of EPOXY ADHESIVE should be approximately 2mm.

- The PROSEAL is then immediately embedded into the fresh EPOXY ADHESIVE and pressed using a hand roller or a similar suitable tool.

- Make sure that the PROSEAL has good contact with the EPOXY ADHESIVE everywhere.

- Then a second layer of EPOXY ADHESIVE is applied on top, so that the edges of PROSEAL are over coated on a width of minimum 40mm.

- Also apply EPOXY ADHESIVE at a width of at least 20mm, so that it covers the substrate next to the PROSEAL.

- Laying of 200-250 GSM Geotextile Membrane or any board over the TPE tape, this will protect the waterproof tape while doing the screed.

- While doing the Screed, Open the gap & maintain the gap for expansion contraction of the Joint and the Tape.

- If it is a normal foot traffic, Lay 1.25mm GI or Aluminium plate fixed with one sided screw.

- If it is a driveway, Top layer will be fixed with Aluminium or GI Chequered Plate with a Minimum thickness of 5mm to protect the entire system from the top with one sided screw

Application Methodology of PROSEAL – Expansion Joint Tape: (Vertical Area)

Surface Preparation:

- Surfaces must be clean, sound and dry. All the broken edges should be repaired with the high strength readymade mortars and all the joint should be straight.

- Surfaces should be free from dust, oil, grease and other similar contaminants.

Mixing – EPOXY ADHESIVE:

- Premix the “A” and “B” components separately.

- Then add the “B” component to the “A” component and mix them until the mixture is uniform in colour.

- For mixing, use a low speed mechanical mixing device with a suitable mixing paddle.

Application:

- EPOXY ADHESIVE is applied to the prepared substrate on both the sides of the joint so that both sides of the PROSEAL are embedded into the

- EPOXY ADHESIVE on a width of at least 40mm. The layer thickness of EPOXY ADHESIVE should be approximately 2mm.

- The PROSEAL is then immediately embedded into the fresh EPOXY ADHESIVE and pressed using a hand roller or a similar suitable tool.

- Make sure that the PROSEAL has good contact with the EPOXY ADHESIVE everywhere.

- Then a second layer of EPOXY ADHESIVE is applied on top, so that the edges of PROSEAL are over coated on a width of minimum 40mm.

- Also apply EPOXY ADHESIVE at a width of at least 20mm, so that it covers the substrate next to the PROSEAL.

From the ground level, up to the 7 feet of Finished floor level lay 1.2 mm GI or Aluminium Plate Fixed with both sided screws. (For Vertical Surface)

* Proseal Expansion Joint tape can be Paintable with any Acrylic/any hybrid UV resistant coating systems. (For Vertical Surface)

PRONIL PROSEAL applications

- Construction joints and cracks.

- Future movements of the construction without causing damages.

- Basements.

- Tunnel construction.

- Around metal surfaces.

- Swimming pools.

- Cable and pipe penetrations.

- Sewage treatment plants.

PRONIL PROSEAL Joint Sealing Tape is a high-quality, versatile product that can be used in a wide range of building applications.

About PRONIL Construction Chemicals

PRONIL specializes in manufacturing high-performance Acrylic Swellable Bars, Bentonite Hydrophilic Waterstops and Expansion Joint Tapes for construction for two decades. They also have a wide range of Expansion Joint tapes and Waterproofing flexible Joint sealing tapes.

To know more about the product range, visit:- https://www.pronil.com/ or contact – +91 9489058644