What is and what could have been?

Let’s think of a hypothetical scenario, wherein a recent earthquake struck a region with a history of seismic activity, a traditional masonry building suffered severe damage due to the lateral forces generated by the earthquake. The structure collapsed, resulting in casualties and extensive property damage.

Now, let’s imagine that instead of a traditional masonry building, there was a Pre-Engineered Building (PEB) in the same location.

By having a PEB in the same location, the community could have experienced fewer casualties, reduced property damage, and a quicker recovery process after the earthquake. PEBs contribute significantly to earthquake protection and resilience, making them a valuable solution for earthquake-prone regions.

Intrigued? Let’s go deep

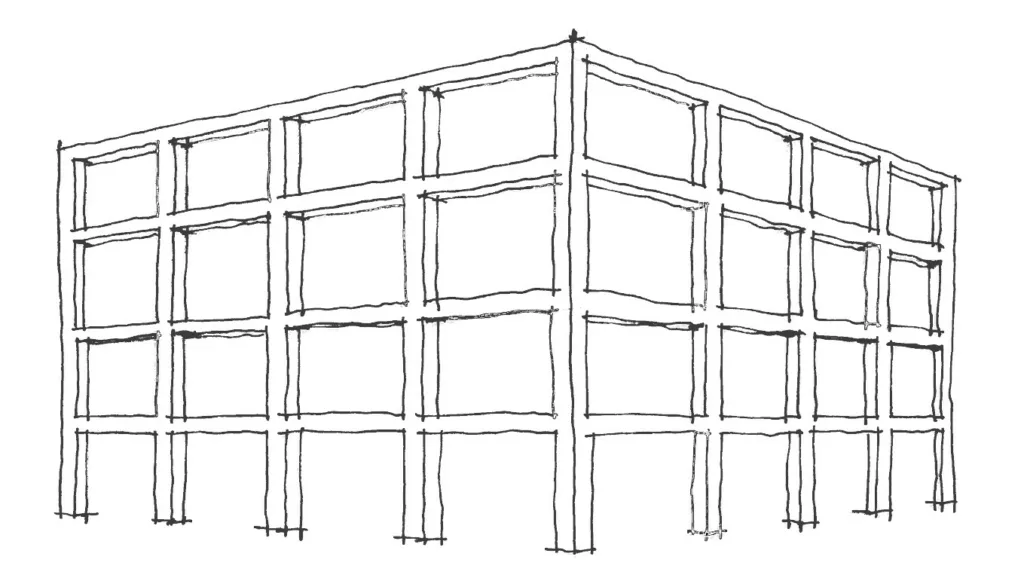

Pre-Engineered Buildings (PEBs) play a crucial role in earthquake protection and resilience. These buildings are designed and manufactured off-site, utilizing advanced engineering techniques and high-quality materials. Their inherent flexibility and ductility make them highly suitable for withstanding the lateral forces generated during seismic events. When an earthquake occurs, the PEB can efficiently absorb and dissipate energy, significantly reducing the risk of structural failure.

Advantages of PEB for Earthquake Protection:

Pre-Engineered Buildings (PEB) play a crucial role in earthquake-prone regions due to their unique design features and construction methods that enhance seismic resilience. Its advantages includes;

- Ductility: PEB structures are designed with high ductility, allowing them to undergo significant deformations during earthquakes without experiencing catastrophic failure. This ductility enables the building to absorb seismic energy and dissipate it harmlessly, ensuring the safety of its occupants.

- Reduced Inertia Forces: PEB buildings are lighter than conventional structures made of materials like concrete and masonry. The reduced mass results in lower inertia forces during seismic events, minimizing the demands on the structure and enhancing its seismic performance.

- Efficient Seismic Force Distribution: PEB buildings use bolted connections and flexible framing systems, which allow the building to sway and distribute seismic forces more efficiently. This feature reduces stress concentrations and enhances the building’s overall earthquake resistance.

- Thorough Seismic Analysis and Design: PEB structures undergo rigorous seismic analysis during the design phase. Advanced computer simulations model earthquake loads and assess the building’s response, ensuring it meets required seismic standards and performs well during seismic events.

- Retrofitting Capabilities: PEB components can be used for retrofitting existing structures to improve their seismic performance. This approach is beneficial for older buildings that may not have been originally designed to withstand seismic forces.

- Redundancy and Load Paths: PEB systems are designed with redundant load paths. In case of localized failure, there are alternative load-bearing routes to redistribute forces, enhancing the building’s overall seismic resilience.

- Faster Construction: PEB components are manufactured off-site and delivered ready to assemble. This prefabrication process reduces on-site construction time, minimizing exposure to seismic hazards during construction.

- Customization and Flexibility: PEB allows for customization and flexibility in design, enabling engineers to tailor the structure to specific seismic requirements and site conditions.

With these advantages, Pre-Engineered Buildings offer a compelling solution for earthquake protection, combining safety, efficiency, and economic benefits in regions susceptible to seismic activity.

Different types of PEB frame for earthquake prone areas

Choosing the right PEB frame is not merely a construction decision; it is an investment in safety and security. There are several types of frames that provide earthquake protection and structural stability for earthquake prone areas. Each of them are discussed below;

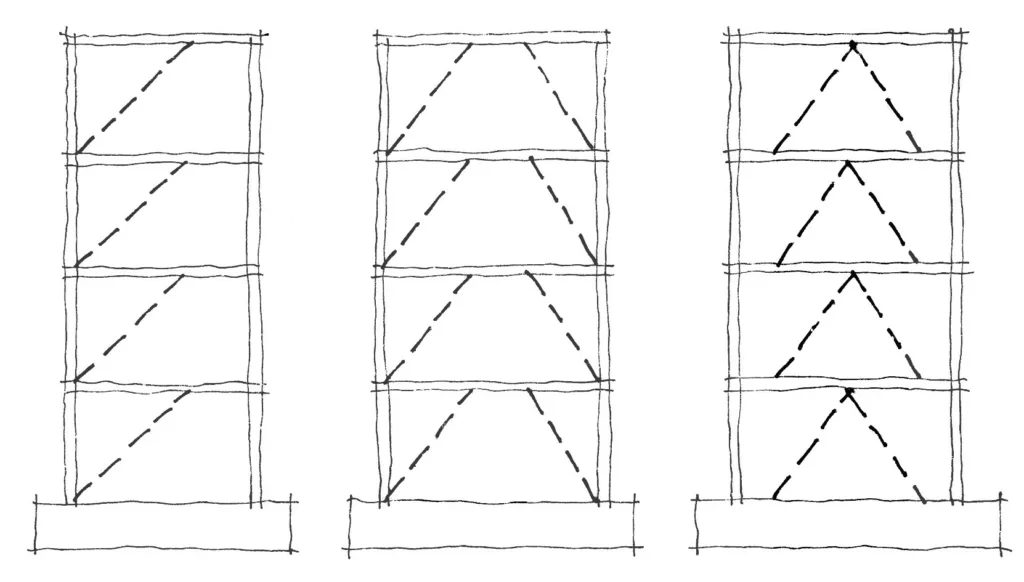

1. Moment-Resisting Frame (MRF): MRF is one of the most effective seismic-resistant PEB frame systems. It employs rigid connections between columns and beams, allowing the frame to withstand lateral forces during an earthquake. These connections enable the structure to flex and dissipate seismic energy, minimizing damage and maintaining overall stability.

2. Braced Frame (BF): Braced frames consist of diagonal braces that connect beams and columns. These braces effectively absorb and redirect lateral seismic forces, reducing the building’s sway and enhancing its earthquake resistance. BF systems are commonly used in PEBs where architectural considerations or functional requirements limit the use of MRFs.

3. Eccentrically Braced Frame (EBF): EBFs are an advanced version of the braced frame, where the braces are intentionally offset from the centerline of the columns. This design enhances the structure’s energy dissipation capacity during earthquakes, offering superior protection against seismic forces.

4. Dual System Frame (DSF): Dual system frames combine two different lateral load-resisting systems, typically a moment-resisting frame with a braced frame or shear walls. The integration of these systems enhances the overall seismic performance and ensures redundancy, making the PEB more resilient against earthquakes.

5. Shear Wall Frame: In this system, reinforced concrete or steel walls are incorporated into the PEB’s design to resist lateral forces. Shear walls act as vertical cantilevers, providing substantial stiffness and strength to counteract seismic loads.

6. Composite Frame: Composite frames combine the use of both steel and reinforced concrete elements. This hybrid construction approach optimizes earthquake resistance, as steel provides ductility and flexibility, while concrete contributes to strength and stiffness.

Each of these PEB frame types can be customized and engineered based on the specific seismic zone and building requirements. By selecting the appropriate frame system and implementing other earthquake protection measures, PEBs can significantly enhance safety and minimize damage during seismic events.

How to select the right PEB frame?

Selecting the best PEB (Pre-Engineered Building) frame for earthquake protection involves careful consideration of several key factors. Here are the steps to guide the selection process:

1. Seismic Zone Assessment: Determine the seismic zone in which the building will be located. India has different seismic zones with varying levels of earthquake risk. Understanding the seismicity of the area will help in designing a suitable PEB frame.

2. Building Height and Configuration: Consider the height and configuration of the building. Taller buildings may require different types of PEB frames to accommodate lateral forces effectively.

3. Occupancy and Building Use: Identify the purpose of the building and its intended use. Different occupancies have varying requirements for earthquake resistance. For example, a hospital or a critical infrastructure facility may require higher levels of earthquake protection than a warehouse.

4. Soil Conditions: Assess the soil conditions at the building site. The type of soil can significantly influence the building’s response to seismic forces. The soil’s ability to amplify or dampen seismic waves should be considered in the frame selection.

5. Engineering Analysis: Conduct a detailed engineering analysis to evaluate the seismic performance of different PEB frames. This analysis should consider the building’s response to ground motion and its ability to absorb and dissipate seismic energy.

6. Reinforcement and Connection Design: Ensure that the PEB frame is appropriately reinforced and designed with adequate bolted connections to withstand seismic forces. Proper detailing of connections is crucial for earthquake resilience.

7. Compliance with Local Codes: Ensure that the selected PEB frame complies with local seismic codes and regulations. Local building codes often prescribe specific requirements for earthquake-resistant construction.

8. Expert Consultation: Seek guidance from experienced structural engineers and PEB manufacturers who have expertise in earthquake-resistant design. Their insights can be invaluable in selecting the best PEB frame for earthquake protection.

PEB in India

PEB (Pre-Engineered Buildings) has become increasingly relevant and essential for earthquake-prone regions in India. As a country situated in a seismically active zone, India faces the constant threat of earthquakes. Several factors contribute to the rising demand for PEB in earthquake-prone areas in India:

1. Seismic Vulnerability: Many regions in India are classified as earthquake-prone zones, with varying degrees of seismic hazard. As awareness about seismic vulnerability increases, there is a growing emphasis on constructing earthquake-resistant buildings to minimize damage and loss of life during earthquakes.

2. Safety Regulations: The Indian government has implemented stricter building codes and safety regulations for earthquake-resistant construction. PEB structures, with their inherent seismic resilience and ductility, align well with these regulations, making them a preferred choice for developers and builders.

3. Rapid Urbanization: India’s urban population is continuously growing, leading to increased construction activities. As cities expand into areas with higher seismic risk, the demand for earthquake-resistant building solutions like PEB rises to ensure the safety and well-being of urban dwellers.

4. Sustainability and Cost-Effectiveness: PEB structures are often considered environmentally friendly and cost-effective due to their efficient use of materials and reduced construction waste. As sustainability becomes a priority in construction practices, PEB becomes a preferred choice for earthquake-resistant and eco-friendly buildings.

5. Time-Efficiency: PEB offers the advantage of faster construction timelines compared to conventional construction methods. In earthquake-prone areas, there may be a need for quick reconstruction and retrofitting of structures after seismic events, making PEB an attractive option due to its rapid assembly and cost-effective approach.

Conclusion

‘Prevention is better than cure’, same goes for buildings. By being aware of the advantages of earth resistance structures such as PEB you can avoid catastrophic damage and ensure the safety and well-being of occupants during earthquake.