Seismic resistance is important for buildings and structures because it ensures the safety of occupants and the preservation of property in the face of potentially catastrophic earthquakes. Proper seismic design, construction techniques, and the right selection of materials can help buildings and structures to withstand the powerful forces generated by seismic events, reducing the risk of collapse and minimizing potential damage. Therefore, prioritizing seismic resistance is not only a matter of safety but also a strategic and economic imperative.

One key area of focus for seismic resistance is reinforcing structural elements, as they are often vulnerable to damage during seismic activity, particularly at critical points. The dynamic shaking and ground motion associated with earthquakes can have various adverse effects on these vital components. A significant challenge arises from the formation of cracks in the structural materials, which weakens the overall integrity and load-bearing capacity of the structure. These cracks can also allow water infiltration and trigger corrosion of the underlying steel reinforcement, further compromising the longevity of the buildings and structures. In severe cases, excessive lateral movement due to seismic activity can lead to structural failure, posing a significant safety risk.

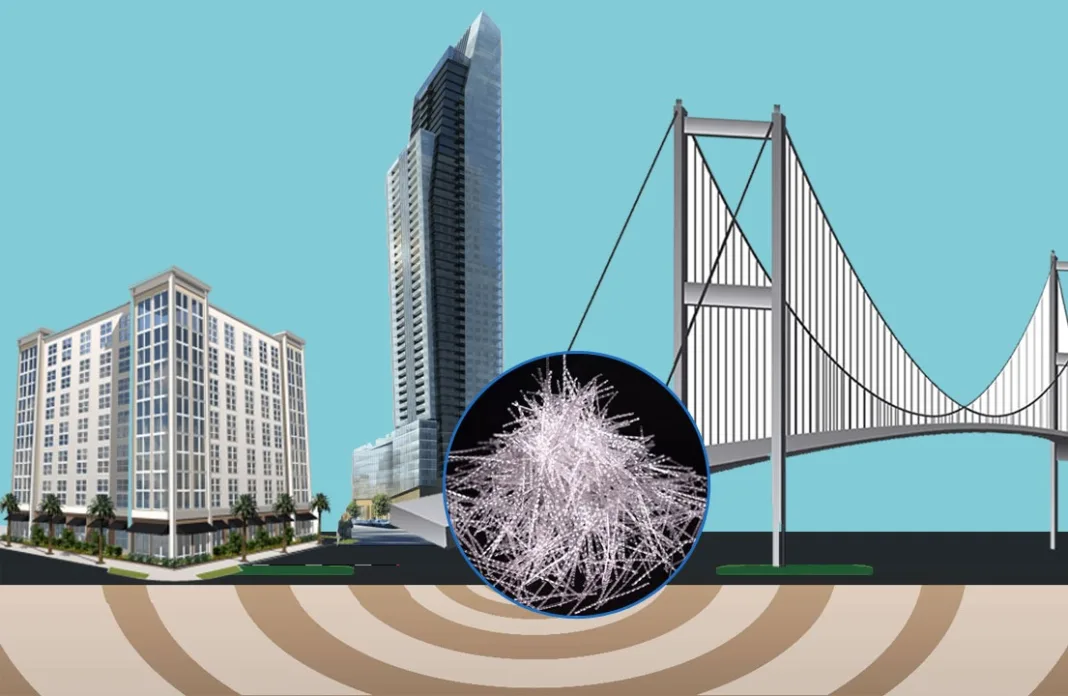

Effects of Earthquakes on Buildings and Structures:

1. Lateral Displacement: Seismic ground motion can cause structural elements to move laterally, resulting in horizontal displacement. This lateral movement can lead to tilting, bending, or even the collapse of structural components, compromising the overall structural integrity.

2. Flexural Cracking: Seismic forces induce bending moments in structural elements, leading to the formation of cracks. These cracks can weaken the components and reduce their load-carrying capacity. Severe cracking may require repairs or replacement.

3. Shear Forces: Seismic events can subject structural elements to shear forces. These lateral forces can cause the components to shear and deform, potentially leading to structural failure if they exceed the element’s capacity.

4. Foundation Movement: The ground shaking during a seismic event can result in movement or settlement of a structure’s foundation. If the foundation shifts, it can affect the structural element’s stability and load-bearing capacity, increasing the risk of structural damage or failure.

5. Pounding and Collisions: Adjacent structural components may collide or “pound” against each other during an earthquake due to lateral movement. This can lead to further damage, including additional cracking or structural misalignment.

Enhancing Seismic Resilience Through Polypropylene Fiber Reinforcement:

One effective approach to address earthquake challenges is through Synthetic Fiber Reinforcement. By incorporating fibers into the concrete mix, the structural elements gain enhanced tensile strength and ductility, making them more resistant to cracking and better capable of withstanding the dynamic forces of seismic events. This reinforcement minimizes the formation of cracks, preventing water infiltration and corrosion, ultimately strengthening the overall integrity and load-bearing capacity of buildings and structures.

Innovative Fiber-Reinforced Concrete (FRC) materials, particularly Polypropylene (PP) Fibers, can significantly improve the seismic performance of structural elements by mitigating damage at critical points. These fibers create a three-dimensional reinforcement within the structural material, effectively distributing stresses and limiting crack formation and propagation. Their lightweight nature simplifies handling and installation, expediting construction processes and reducing labour costs. Choosing the right polypropylene fiber product is essential and Kalyani Polymers Pvt Ltd., under the brand name FIBERCRETE®, manufactures Synthetic Polypropylene Fibers that elevates seismic resistance in various structural elements.

Advantages of FIBERCRETE® Polypropylene Fibers for Seismic Resistance:

- Enhances the ductility of the structural material, allowing components to deform and absorb seismic energy without sudden failure.

- Aids in controlling cracking in the material, crucial for maintaining the integrity of structural elements during seismic events.

- Improves material toughness, reducing the risk of brittle failure and increasing the ability of components to withstand seismic forces.

- Helps mitigate material shrinkage and settlement, which maintains the alignment and stability of structural elements.

- Improves material fatigue resistance, which is essential for structures exposed to cyclic loading during seismic activity.

Features of FIBERCRETE® Polypropylene Fibers:

- Greater Young’s Modulus

- Non-Corrosive

- Acid & Alkali Resistance

- Chemically Inert

- Hydrophobic (do not absorb water)

- Decreases the dead weight of the structural element

- Uniform Dispersion in the material

- Reduces water permeability in the material

- Reduces the dead load of structural elements

- Provides 3D reinforcement for structural components

- Lightweight with a high fiber count

Applications of FIBERCRETE® Polypropylene Fibers:

1. Residential Buildings:

- Used in foundations, walls, and slabs to prevent cracks and improve earthquake resistance for the safety of occupants.

2. Commercial Buildings:

- Strengthening key structural elements like columns and beams to enhance overall earthquake resilience and reduce potential damage.

3. Bridges and Overpasses:

- Addition to concrete mix for bridge support structures, making them more robust and capable of withstanding lateral forces during earthquakes.

4. High-Rise Buildings:

- Used for additional strength and flexibility in the core, columns, and shear walls, reducing structural damage and ensuring safety.

5. Industrial Facilities:

- Reinforcement in floors and walls of industrial structures to protect equipment and goods, minimizing damage and production downtime during seismic events.

6. Infrastructure Projects:

- Used in critical infrastructure like tunnels, dams, and retaining walls to maintain stability during earthquakes and ensure continued functionality.

7. Historical and Cultural Sites:

- Incorporation into restoration processes to strengthen original materials and protect historical and cultural sites from earthquake damage while preserving their architectural integrity.

The utilization of Fibercrete Polypropylene Fibers in various structural elements for seismic resistance offers a promising and innovative solution. These fibers enhance the structural integrity of components, making them more resilient to seismic forces. By reducing cracking and improving ductility, these polypropylene fibers significantly increase the safety and longevity of structures in earthquake-prone areas.

About Kalyani Polymers Pvt. Ltd; the holding company of FIBERCRETE®

Kalyani Polymers Pvt. Ltd., manufacturers synthetic concrete fibers under the brand name FIBERCRETE®, a world-class synthetic micro and macro concrete fiber products under the “Make in India” and “Atmanirbhar” initiatives to meet the construction sector’s requirements in India and globally. They hold a valid BIS & CE Certifications, reflecting their commitment to quality. Kalyani Polymers development is built on the pillars of Quality, Service, and Innovation. They customize concrete fiber products for each client after a thorough investigation of their requirements and needs. The company’s ability to expand its product range continuously and apply new techniques to enhance systems ensures efficient manufacturing and innovation.

“Neo Fibers For Next Generation Concrete”

FIBERCRETE

46/1, 11th KM Off Kanakapura Road, Doddakalasandra. Bangalore – 560062 Karnataka, INDIA

Phone: +91-80-40991198, +91-80-40991001

Email: sales@fibercrete.in

Website: www.fibercrete.in