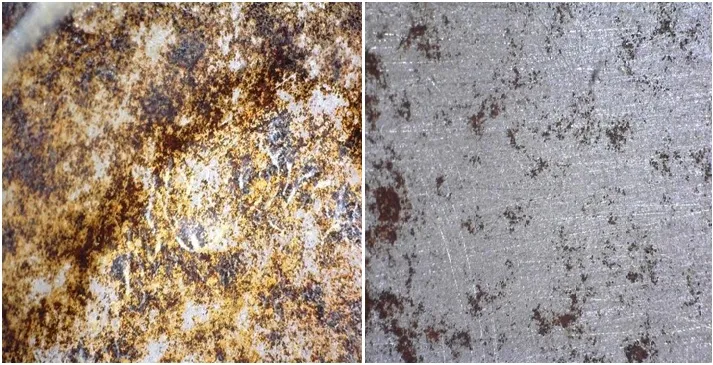

Steel structures are not immune to corrosive and saline environments. Welded joints is another cause of high rates of corrosion. In many Industries welding is not possible due to fire hazard Leaching of chemicals in soil current flow are also cause of corrosion. Addressing this issue needs expert supervision, one such group providing metal protection is Dimple Chemicals & Services Pvt Ltd.

— Advertisement —

They have been a pioneer in surface preparation products, surfactants & performance chemicals for the last 30 years. The manufacturing plant near Pune has spread over 60,000 sq. ft. and has a production capacity of 12,000 TPA. The company contains an in-house R & D facility and a well-equipped quality control laboratory to help us in meeting the stringent demands of customers from a wide spectrum of industries.

Metal Surface Protection Technology

Over the years we have developed and added innovative technologies for surface preparation and corrosion control metal surfaces. These technologies are energy-efficient and environmentally friendly. During the last decade, the technologies have been deployed with excellent results for varied applications.

Range of Surface Preparation Products

Dimple Chemicals have a wide array of products for surfaces to remove unwanted particles in the structure. Each of them is given below.

Steripure 10: The growth of algae-fungi on a humid surface is a common problem. Steripure 10 is an antibacterial, antifungal water base solution to remove algae-fungi from the surface by killing roots. This also cleans nanoparticles, dirt/duct from the surface.

DuraClean OD: This is an organic polymer for emulsification & dispersion of oil and grease spilled on the surface. This emulsified oil/grease can be easily removed by water wash. De-oiled & de-greased surface is a primary requirement for any process or application.

DuraClean WR: This patented (Indian & European) process technology converts unwanted substrate (burr) on the metal surface by crystal structure modification into docile form. Growth of oxide is in mathematical progression hence burr on the surface is to be as low as possible. This method of surface preparation brings burr on a surface below 25 microns. This product improves the surface texture. It is also anti-static and biodegradable. DuraClean WR also controls embedded, Bio & bi-metallic corrosion.

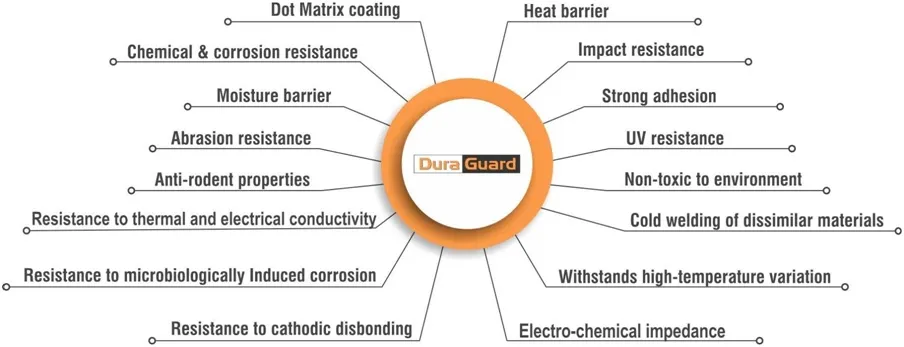

DuraGuard: DuraGuard technology gives better resistance against corrosion, abrasion, UV and impact resistance. It contains a unique combination of organic and inorganic materials consisting of Ceramic Ironite, Active ceramic, cement & water-miscible modified epoxy. This is a dot matrix coating hence gives strong adhesion with any substrates like metal, concrete, wood, PVC and any other substrate. The product gives better electro-chemical impedance, chemical resistance to various corrosive chemicals and has high breakdown voltage. It is no-toxic with thermal resistance and ant-rodent properties. DuraGuard also has an innovative ‘cold welding property which helps to form a strong bond between dissimilar materials like metals, glass, plastic, wood, ceramic materials etc.

For more details, visit- www.dimplechem.com

Email – info@dimplechem.com