The concept of the residential building envelope has undergone a massive transformation in recent years. Historically viewed primarily through the lens of weatherproofing and structural integrity, modern facades are now recognized as critical drivers of property valuation and buyer psychology. For today’s residential developers, architects, and civil engineers, successful projects require a highly calculated integration of structural cladding and exterior finishing.

A well-engineered facade must balance thermal performance, moisture management, and structural load with high-impact aesthetics. When developers master this intersection—pairing high-performance materials with strategic color psychology—they not only ensure the longevity of the structure but also maximize curb appeal. In a competitive real estate market, this ultimately accelerates the property’s time-on-market and justifies premium pricing models. This article explores the building science, material integration, and design strategies required to optimize modern residential exteriors.

The Evolution of the Building Envelope: From Monolithic to Mixed-Material

For decades, monolithic exteriors like traditional stucco, brick veneer, or uniform vinyl siding dominated residential subdivisions. However, contemporary architectural trends demand more dynamic, texturally rich exteriors. Today’s high-yield residential developments increasingly rely on mixed-material facades that provide both visual interest and superior environmental resilience.

Modern building envelopes frequently combine three or more distinct architectural claddings. A single elevation might feature heavy-duty fiber cement boards on the primary volume, thermally modified timber accents around the fenestration, and standing seam metal paneling to highlight specific architectural features. While this mixed-material approach offers robust weather resistance and structural durability, it presents a unique aesthetic challenge: without a unifying exterior finish, the facade risks looking fragmented, poorly planned, or visually chaotic.

This is where the strategic application of exterior paint and architectural coatings transitions from a mere decorative afterthought into a crucial structural unifier.

Deep Dive: Cladding Materials and Their Finishing Requirements

To achieve a cohesive look, developers must understand the specific finishing requirements and limitations of the underlying substrates.

Fiber Cement and Engineered Wood

Fiber cement siding and engineered wood products are celebrated in modern construction for their dimensional stability, fire resistance, and immunity to rot and pests. Because these materials often mimic natural wood grain or smooth modern stucco, they serve as excellent canvases for bridging warm and cool tones. Unlike vinyl, fiber cement accepts high-quality acrylic latex paints exceptionally well, allowing for a broader spectrum of color choices without the immediate risk of thermal warping.

Metal Cladding: Standing Seam and Corrugated Panels

The use of corrugated steel and standing seam metal on residential facades introduces a highly durable, industrial edge to the property. Often, these materials are pre-finished at the factory using high-performance fluoropolymer coatings (like PVDF or Kynar 500). Integrating these pre-painted structural elements with the rest of the painted facade requires meticulous color matching and an understanding of how light reflects off different gloss levels.

Masonry, Brick, and Stucco Systems

When integrating traditional masonry or modern Exterior Insulation and Finish Systems (EIFS) into a mixed facade, breathability is the primary concern. Painting these surfaces requires specialized elastomeric coatings or mineral-based silicate paints that allow water vapor to escape the substrate while preventing bulk water intrusion.

Strategic Color Selection for Mixed-Material Facades

When engineering a mixed-material facade, the structural cladding dictates the physical texture, but the exterior paint dictates the spatial flow and perceived mass of the building. To unify disparate materials, developers are moving away from high-contrast, disjointed designs.

Instead, to seamlessly tie the building envelope together, developers are relying on cohesive, modern exterior house paint palettes that complement both the structural cladding and the surrounding landscape. By anchoring the development within its environment, the architecture feels intentional rather than imposed.

Anchoring the Structure with Color Psychology

The strategic placement of color can alter the perceived geometry of a home.

- Grounding the Structure: Utilizing darker, heavier tones on the lower levels (such as on masonry or heavy fiber cement base-boards) visually anchors the home to the site.

- Elevating the Roofline: Conversely, using lighter, highly reflective colors on upper stories or projecting volumes draws the eye upward, making the structure appear taller and more expansive.

- Softening Industrial Elements: To mitigate the harshness of metal cladding, architects frequently specify ultra-matte exterior acrylics on adjacent smooth surfaces. Deep, light-absorbing colors like charcoal, iron ore, or muted navy can ground the reflective qualities of the metal, transforming a potentially cold, industrial material into a sophisticated architectural feature.

The Science of Exterior Finishes: Building Physics Meets Aesthetics

Selecting an exterior finish is not just a matter of design preference; it is a vital component of building science. The physical properties of the chosen paint heavily influence the thermal performance and lifespan of the underlying cladding.

Light Reflectance Value (LRV) and Thermal Expansion

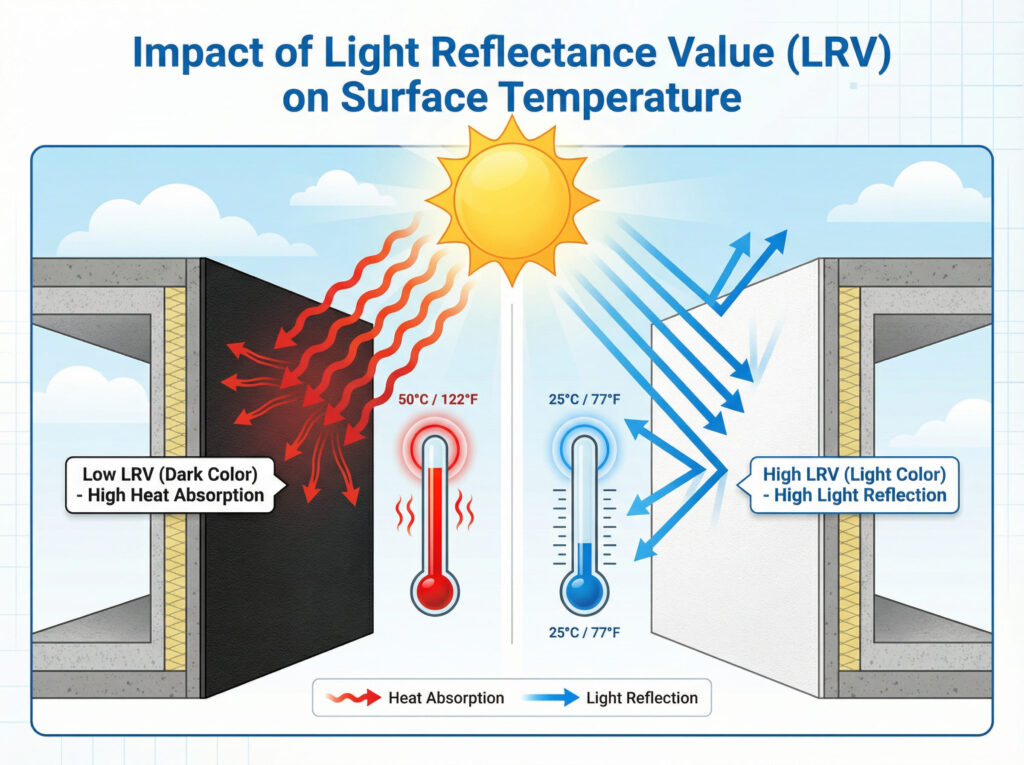

For architects and builders, the Light Reflectance Value (LRV) of a chosen paint color is a critical metric. LRV measures the percentage of light a paint color reflects, on a scale from 0 (absolute black, absorbing all light and heat) to 100 (pure white, reflecting all light).

Specifying low-LRV (dark) colors on composite or PVC-based cladding can lead to excessive heat absorption. This significantly increases the risk of thermal expansion, substrate warping, and premature coating failure. In fact, many siding manufacturers will void structural warranties if a paint with an LRV below 55 is applied. Developers must consult with coating manufacturers to utilize “vinyl-safe” colorants—specialized pigments that reflect infrared light even in darker shades—to bypass these thermal limitations.

Moisture Management and Coating Permeability

The building envelope must be allowed to “breathe.” If a high-build, impermeable paint is applied over a porous substrate like brick or stucco, trapped moisture from interior condensation or minor exterior leaks will vaporize as the sun hits the facade. The resulting hydrostatic pressure will push the paint off the wall, leading to blistering and peeling. Specifying paints with high permeability (perm ratings) ensures that the facade can dry out naturally, preventing mold growth and structural rot within the wall cavity.

UV Degradation and Pigment Retention

South and west-facing facades endure intense ultraviolet (UV) radiation. Over time, UV rays break down the chemical binders in paint (leading to chalking) and destroy organic colorants (leading to fading). Vibrant reds, yellows, and blues are particularly susceptible to UV degradation. To combat this, builders should specify 100% acrylic latex paints formulated with inorganic pigments and high levels of titanium dioxide (TiO2), which naturally block UV rays and ensure the facade retains its curb appeal for years.

Climate-Responsive Finishing Strategies

A paint specification that works for a residential development in a dry, arid climate will fail catastrophically in a coastal or freeze-thaw environment. Tailoring the finish to the local climate is a hallmark of expert architectural planning.

- Coastal Environments: Homes subjected to salt spray, high humidity, and intense sun require hyper-durable coatings. High-build elastomeric paints are often specified here to create a thick, waterproof barrier that resists salt-induced corrosion on metal fasteners and prevents moisture intrusion in masonry.

- Freeze-Thaw Climates: In regions with harsh winters, exterior claddings expand and contract violently as temperatures fluctuate. Paints used in these zones must possess exceptional elasticity. If the coating is too brittle, it will micro-fracture during the first freeze, allowing water to enter, expand as ice, and destroy the substrate from the inside out.

Cost-Benefit Analysis: CAPEX vs. OPEX in Exterior Finishes

For property developers, the initial capital expenditure (CAPEX) of architectural finishes must be heavily weighed against long-term operational expenses (OPEX), maintenance cycles, and immediate property valuation.

Opting for premium exterior coatings—such as high-build acrylics, siloxane-based paints, or advanced elastomeric systems—requires a higher upfront budget compared to standard contractor-grade latex paints. However, the return on investment is undeniable.

Premium finishes provide superior elasticity and UV resistance. They bridge hairline cracks, flex with structural settling, and provide an impenetrable barrier against moisture infiltration. This drastically reduces the frequency of repainting cycles (stretching a typical 5-7 year maintenance window to 12-15 years or more) and significantly lowers the lifetime OPEX of the property. Furthermore, an expertly curated, highly durable exterior palette immediately signals premium construction quality to prospective buyers and appraisers, directly translating to higher valuation and faster sales.

Conclusion: Future-Proofing Residential Developments

The success of modern residential development hinges on the marriage of structural engineering and aesthetic finishing. The building envelope is no longer just a protective shell; it is a canvas where material science, climate responsiveness, and architectural design intersect.

By deeply understanding the physical properties of cladding materials and specifying scientifically sound, visually cohesive exterior color palettes, developers can future-proof their builds. Moving beyond basic aesthetics to embrace the building physics of exterior finishes reduces life-cycle maintenance costs, protects structural integrity, and maximizes the long-term curb appeal of any real estate portfolio.