A growing body of research has found that school facilities can have a profound impact on both teacher and student outcomes. With respect to teachers, school facilities affect teacher recruitment, retention, commitment, and effort. With respect to students, school facilities affect health, behavior, engagement, learning, and growth in achievement. In light of this, World’s First 3D Printed School will soon open in Madagascar.

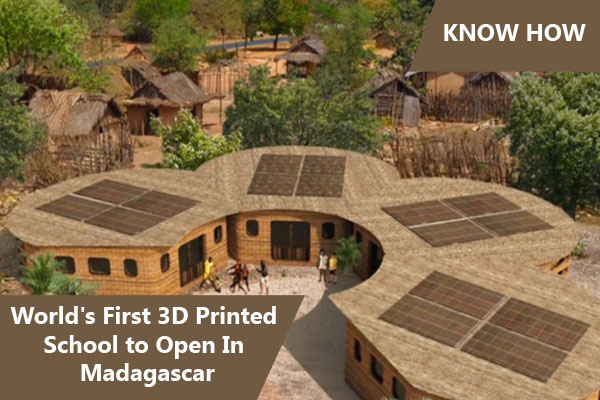

The American philanthropist and founder of the Thinking Huts nonprofit, Maggie Grout, has come up with an innovative concept to help make education more accessible around the world: a life-size 3D-printed school. The first such school is due to open its doors in Madagascar. To bring this school project to life, Maggie Grout teamed up with the architectural design agency Studio Mortazavi, based in San Francisco. The pilot project will be built on the university campus of the Ecole de Management et d’Innovation Technologique (EMIT), in the city of Fianarantsoa in Madagascar, and will welcome students from preschool through high school. Thinking Huts intends to use 3D printed schools to make quality education more accessible in the future. This seemed particularly pertinent in Madagascar. Possessing a need for education infrastructure, stable political outlook in an emerging economy, opportunity for growth, as well as renewable energy potential (the school’s design incorporates solar panels), the country was the perfect location for the first ever 3D printed school.

3D printing decreases construction time from months to days, reduces our carbon footprint, and addresses a real need for education infrastructure,” explain the project creators in their video presentation. With vertical farms and 3D-printed walls, this hybrid school of a new kind is designed using reusable materials and in line with environmentally responsible standards. The school is scheduled to open in summer 2021-2022 in Madagascar, which falls between December and March. With vertical farms and 3D-printed walls, this hybrid school of a new kind is designed using reusable materials and in line with environmentally responsible standards. The school is scheduled to open in summer 2021-2022 in Madagascar, which falls between December and March. Maggie Grout hopes to expand this school model to other regions of the world once the technical process has been fine-tuned. A crowdfunding campaign titled “Thoughtful Giving” hopes to collect US$350,000 to support the pilot project in Madagascar, as well as the construction of the next three schools.

Relying on Hyperion Robotics’ technology, the walls of the school will be built with an extrusion-based construction 3D printer. Of course, additive manufacturing construction methods are still far from comprehensive and some parts of the school cannot be 3D printed. This includes the roof, doors and windows, all of which will be made from locally-sourced materials. Moreover, in order to have a lasting effect on the community, Thinking Huts also formed partnerships with locals. This was so that they could teach members of the community how to use the 3D printer, thus allowing them to build more schools in the future. Additionally, the idea has been entrenched in the design of the school which possesses a beehive-like structure that facilitates expansion of the building.

One of the biggest benefits that 3D printers have presented to construction workers is a reduction in injuries in the field. Considering that building with concrete is difficult-even dangerous-this is a welcome improvement. Not only do workers have an easier time doing their job, but employers have less worker’s compensation paperwork to wade through due to injuries on the job. Another improvement is a considerable reduction of material waste. 3D printers use the exact amount of concrete needed for the wall, floor, or whatever it is that you want to build. Builders and GCs don’t have to order in bulk because they’ll know exactly how much material they need. Not only is this a more sustainable, environmentally friendly way to build, but it also results in reduced costs for the contractor.

Conclusion

Using a 3D printer also allows construction companies to work in markets that might have otherwise been inaccessible to them before. And for new construction companies, having a 3D printer on hand could set them apart from companies that have been around for a few decades and are resistant to change. Similarly, traditional and established construction companies could utilize 3D printers to make sure they remain relevant in the market. Essentially, 3D printers can be used as a means to enter a new market but also to give an already established company a competitive edge.

Image Source: campuslately.com