Thermoplastics are a core part of many things that we use in day-to-day life, both at an individual level and during manufacturing or other work-related purposes. While thermoplastics are incredibly useful and heavily varied, not many people actually understand why they matter or how they are even used.

Whether you need more knowledge of thermoplastics for work or have been looking into thermoplastics for a specific project of your own, it is important to know at least the basics. What are thermoplastics, and how are they used in daily life?

What are Thermoplastics?

Thermoplastics are plastic-like materials that can be molded and shaped when heated, making them extremely useful for manufacturing. Plastic bottles are a good example of what thermoplastics can achieve – sealed plastic containers that conform to a defined shape or mold.

This means that thermoplastics can appear in almost any kind of product, from food containers and drink bottles to toys, electronics, and even clothing. If you buy something that contains plastic, then it will usually use thermoplastics since they are much more versatile than other plastic types.

However, there is not just one type of thermoplastic. There are multiple different options when it comes to thermoplastics, and all of them are best used for wildly different things, despite being the same kind of material at their core.

Types of Thermoplastics

While thermoplastics generally all have the same benefits – flexibility, low cost for high-volume production, easy remodelling – there are a lot of different varieties that might be used for each project. There is also no ‘best’ type of thermoplastic for all situations, so they have to be chosen carefully.

Knowing the different types of thermoplastic can be important if you are planning on using them for any projects, either through work or for personal reasons. Many people do not even realize that certain common materials, such as nylon are technically thermoplastics.

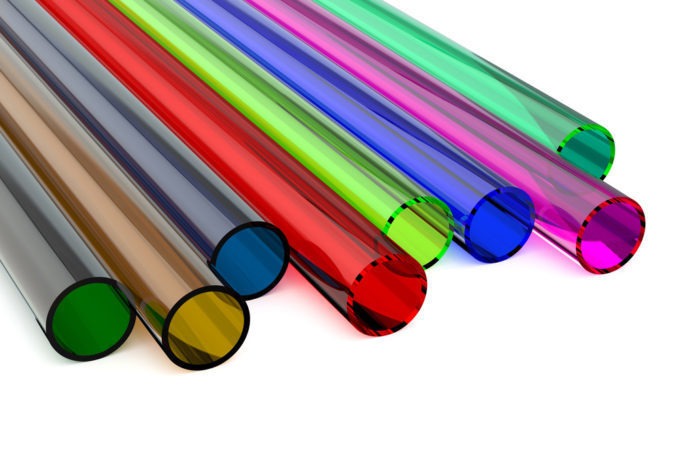

Acrylic

Acrylic is used in hundreds of different industries, acting as a great replacement for glass – it is lighter, more durable, more flexible, and offers all of the same benefits that glass would. This makes it a common sight in things like helmets, lenses, aircraft windows, cars, and plenty of different toys or decorations.

You will also see acrylic being used for paint, medical devices, screens (including screens for digital devices), and furniture. It is a very widespread material that can have hundreds of different uses, and it can always be recycled to be re-used later on.

Nylon

Nylon might seem like a regular fabric at first, but it is actually a silky thermoplastic that can be used in a huge range of clothing and fabric-based items. Not only is nylon heat resistant, but it is quite strong when used properly, making it a common sight in heavy-duty clothing.

Nylon will often appear in things like flak vests, ropes, stockings, and even mixed in with other fabrics as brand new products. On its own, nylon is useful, but it becomes even more versatile when combined with other materials to form stronger fabrics.

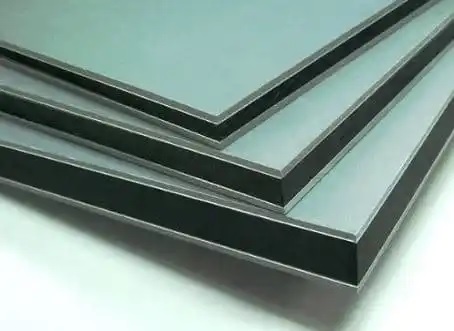

Polycarbonate

Polycarbonate materials are heat-resistant, durable, translucent, and can even fight off flames if they are ignited. They are also incredibly flexible and can be used in countless different ways, including for medical equipment and containers that are meant to hold food for long periods of time.

You can also see polycarbonate getting heavy use in electric devices – such as data storage devices and components used in electronics – as well as car parts and construction materials. Like nylon, polycarbonates can become stronger or more varied when combined with other materials.

Polyethylene

Polyethylene is chemical-resistant and can withstand temperature changes well, making it a very valuable material for all kinds of containers, packaging options, and industrial equipment. This ranges from milk containers and drinks bottles to bulletproof vests and machine components.

This material is a very durable one, and not just physically. Polyethylene’s ability to survive through temperature changes means that it is important for a lot of industrial work and can be used for moving parts that other materials are not suited for, like mechanical joints.

Polypropylene

Polypropylene is a very varied material that is used for a lot of electric components, including car batteries and cable insulation. However, it sees a lot of use in varied industries and will also appear in anything from plastic containers and rope to pipe systems and children’s diapers.

Polystyrene

Polystyrene is known for being a ‘disposable’ material, but it has a multitude of uses outside of that. Not only can it be used to create cases for DVDs and CDs, but it is often used as a packing material – whether that is packing peanuts or entire specially-molded pieces of polystyrene packing foam.

Beyond that, it sees use in disposable drinks cups, architectural models, and all kinds of other niche uses. While it degrades slowly, it still has a valuable role in modern life, and many companies rely on it heavily to protect important products during shipping.

Why are thermoplastics important?

Thermoplastics play a core role in our life, and it is easy to forget how important they actually are if you are not fully aware of how they are being used. The average person might use dozens of thermoplastic-based items each day, more if they are involved in actually manufacturing items made using thermoplastics.

Everything from plastic bottles and food containers to medical gear and clothing can contain thermoplastic materials, and there are countless uses for even the most basic varieties. Even without knowing much about thermoplastics, the benefits can become obvious when you realize how many ways they are used.

If you are the kind of person who does a lot of DIY projects, then you will probably have run into thermoplastics before. Many people use thermoplastics in place of normal glass or plastic, creating interesting bits of DIY furniture or decorations that would not be possible with other materials.

On the other hand, people who work for large manufacturing companies may handle thermoplastics on a day-to-day basis – and considering how many uses thermoplastics can have, they appear very often in all industries. Without thermoplastics, manufacturing even some basic items could become much more complex and a lot harder.