A geogrid is geosynthetic material used to reinforce soils and similar materials. Geogrids are commonly used to reinforce retaining walls, as well as subbases or subsoils below roads or structures. Soils pull apart under tension. Geogrids are commonly made of polymer materials, such as polyester, polyvinyl alcohol, polyethylene or polypropylene.

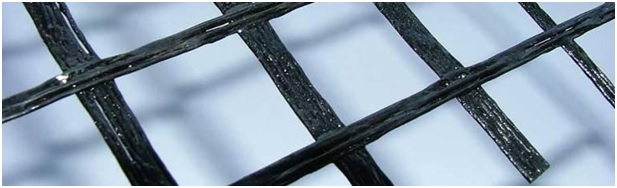

They may be woven or knitted from yarns, heat-welded from strips of material, or produced by punching a regular pattern of holes in sheets of material, then stretched into a grid. The geogrids are manufactured high strength reinforcement grids that come in rolls of various sizes and strengths. The soil can strike through the apertures and the two materials interlock together to give composite behavior.

Manufacturing and functional mechanism of geogrids

There are three methods for manufacturing of geogrids, each of them is explained below.

- Extrusion: In this method, a flat polymeric sheet of material is made into a geogrid by extrusion and holes of desired dimensions are punched in the flat sheet to form the apertures.

- Weaving or Knitting: These geogrids are manufactured by weaving fibrous yarns and apertures are formed in between the flexible joints. These types of geogrids have high tenacity.

- Welding and Extrusion: Tese geogrids have manufactured the extrusion of ribs that is carried out by passing it through rollers, then they are sent to the welding section to form apertures.

The desired reinforcement effect by the geogrid is provided by a combination of the following mechanisms:

- Lateral Confinement- It limits horizontal movements of aggregate and provides lateral confinement by interlocking. It increases stiffness, at equal deformations, it is possible to apply a higher load.

- Increase of load distribution angle- The inclusion of geogrid allows increasing the load distribution angle below rails. In this way the pressure applied to subgrade is decreased, hence settlements and deformations are reduced.

- Tension Member affect- A loading capacity is generated, i.e. an upward vertical force that contributes to support the applied load, thus decreasing the stress applied to subgradE.

Types of geogrids

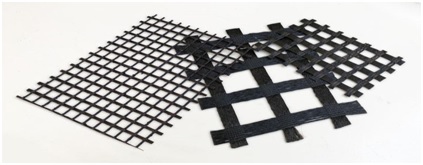

Geogrids are commonly made of polymer materials, such as polyester, polyvinyl alcohol, polyethylene or polypropylene. They may be woven or knitted from yarns, heat-welded from strips of material, or produced by punching a regular pattern of holes in sheets of material, then stretched into a grid. There geogrid types can be categorised based on pattern and manufacturing.

Geogrids based on pattern-

Uniaxial Geogrid: It is known as mono-oriented geogrids, it is a planar grid, which possesses a much higher strength in one direction than in the other direction.

Biaxial Geogrid: It is also known as bi-oriented geogrids, it is a planar grid, which possesses similar strength in both ortho-directions i.e. longitudinal & transversal.

Triaxial Geogrid: These are manufactured from a punched polypropylene sheet oriented in multiple, equilateral directions to form triangular apertures.

Geogrids based on manufacturing

- Extruded geogrid- They are made from polypropylene used for ground stabilisation and soil reinforcement applications. They are flat structures in polymer that are extruded and then pulled: this may be done in one direction or in the two main directions. They are used in soil and road paving reinforcement.

- Woven geogrid- It is manufactured by grouping polymeric—usually polyester or polypropylene—and weaving them into a mesh pattern that is then coated with a polymeric lacquer.

- Bonded geogrid- It is produced by bonding, usually at right angles, two or more sets of strands or other elements.

Different types of geogrids based on manufacturing

Advantages of geogrids

- It is used below roads, under structures and behind retaining walls. They are engineered with large openings or apertures which are made from polymers such as polypropylene, polyethylene or polyester.

- They are used to prevent sliding on long and steep slopes during installation and use of a landfill capping system.

- The geogrid provides high strength and longevity to your wall to help prevent wall failure;resistant to biological degradation and naturally encountered chemicals.

- It can improve the structural integrity of soils in roadways, walls and slopes by reinforcing and confining fill materials and distributing load forces.

- They help soils stand at virtually any desired angle in grade separation applications. In retaining wall and slope applications, geogrids can be combined with a wide variety of facing elements to produce the desired aesthetics for any project.

- Geogrids provide support for the construction of access roads, highways, berms, dikes and structure applications that previously required the use of expensive over-excavating or piling methods on weak subgrades.

- Geogrids are also used in base reinforcement applications to reduce aggregate thickness requirements or extend roadway performance life.

Application of geogrids

Application areas of geogrids

Geogrids have been extensively used for the construction of earth-supported and earth-retaining structures such as mechanically stabilized earth (MSE) retaining walls, steep slopes, and other structures. Its application areas include,

Geogrids for pavements

Geogrid applications in pavement and roadway consist of subgrade improvement, reinforcing the base course, sub-base and surface courses. The outward displacement of railway ballast is arrested and the settlement is reduced when they are reinforced with geogridsIn soft subgrade, the stiffer geogrids perform better than flexible geogrids as the later quickly reacts to the applied load.

Geogrids for retaining wall

Geogrids are used for stabilizing the backfill in retaining walls. The stability of the earth retaining wall depends on the friction angle. Creep and stress relaxation properties affect the performance of geogrids in a retaining wall. In the middle of the retaining wall high strength geogrids must be provided or else the geogrid reinforcement spacing must be reduced.

Geogrids for soil foundation

Both uniaxial and bi-axial geogrids are commonly used in foundation works. The main condition to achieve good stability is the interlocking capacity of geogrid and aggregates. The vibrations are well controlled by geocell reinforcement.

Geogrids for slope stabilization

The geogrid reinforcement in slope influences mainly the slope deformation and stability. The bearing capacity mainly depends on the length of the geogrid. To achieve best performance the aperture size should be approximately equal to 0.2 times the width of the footing. Due to higher tensile strength and longer length, there is a downfall in the displacement of the earthen embankments and increase in the safety factor.

Geogrid for structural elements

In structural components, the geogrids are used as additional reinforcement and as shear reinforcement. To achieve good strength fibers like polypropylene and steel are used.The geogrid reinforcement results in high ultimate load-bearing capacity], improved energy absorption and reduced slippage, shear and bond strength, reduced drying shrinkage and reduced degradation rate.

Other than these geogrids are also used for Dewatering Drainage Filtration, ) Landfill and Environmental Barrier and Surfacing Reinforcement.

Image source – Happho, Surrey Geosynthetics Engineering, Geosynthetics.au, Macaferri.com, Geogridfabric.com, SRW products, Geosynthetica