An asphalt drum mix plant is used for the continuous production of hot mix asphalt that is used for paving across various infrastructure projects. It operates by mixing aggregate and asphalt at high temperatures within a rotating drum, ensuring a uniform blend. The plant’s efficiency lies in producing large volumes of asphalt with consistent quality. Its efficient design, easy operation, and on-site production capability , the plant effectively lowers transportation costs and helps maintain construction schedules.

Asphalt drum mix plants are used for:

- Highway Construction

- Urban and Rural Road

- Airport Runways

- Parking Lots

- Factory roads

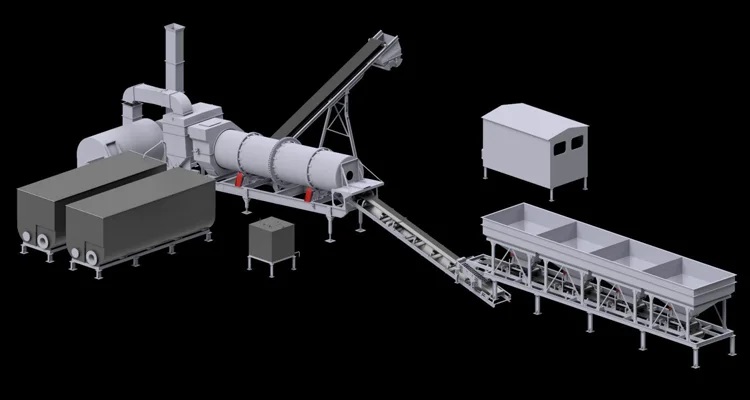

Asphalt drum mix plant components

Asphalt drum mix plants consists of several key components, each playing a important role in the asphalt production process:

- Cold Aggregate Feeder Bins: Stores and supplies different sizes of aggregates in controlled amounts.

- Conveyor System: Transfers the cold aggregates from the feeder bins to the drying drum.

- Drying Drum: Heats and dries the aggregates while mixing them with liquid asphalt.

- Burner: Provides the heat necessary to dry the aggregates inside the drum.

- Asphalt Tank: Stores and supplies liquid asphalt to the drying drum for mixing.

- Filler Unit: Adds mineral fillers to the mix for improved asphalt quality.

- Dust Collection System: Captures dust and particles from the drying process.

- Control Panel: Ensures precise control over the mixing process.

Advantages of Asphalt drum mix plants

- Continuous operation enhances workflow efficiency.

- High-capacity production to meet large-scale project demands.

- Accommodates various asphalt mixes and aggregate sizes.

- Streamlined processes lower overall operational costs.

- Compact design allows for efficient use of space.

- Fewer moving parts simplify maintenance requirements.

- Dust collection systems minimise environmental impact.

- Automated controls offer precise and easy management.

- Quick setup reduces project initiation time.

- Flexibility in production volume to accommodate as per requirement.

- Modular design allows for easy expansion and upgrading.

Types of Asphalt drum mix plants

Batch Drum Mix Plant:

A Batch Drum Mix Plant is designed to mix aggregates and asphalt in discrete batches, ensuring high consistency and quality in each mix. This type of plant is equipped with separate compartments for heating, mixing, and storing, allowing for precise control over the asphalt’s properties. The batch process ensures that each load of asphalt meets stringent quality standards, making it ideal for projects requiring exact specifications and uniformity. Its advantages include flexibility in mix designs and the ability to handle varied aggregate sizes, which is beneficial for complex construction projects and high-quality road surfaces. Applications include urban road construction, specialty pavements, and projects requiring frequent mix changes.

Continuous Drum Mix Plant:

The Continuous Drum Mix Plant operates by continuously mixing aggregates and asphalt, providing a steady and uninterrupted flow of material. This type of plant is characterised by its streamlined process, where aggregates and asphalt are mixed as they move through a rotating drum, resulting in higher production rates compared to batch plants. Its advantages include increased production efficiency, reduced mixing time, and consistent quality of asphalt, making it suitable for large-scale projects. Applications include highway construction, large infrastructure projects, and areas with high traffic volumes where high output is essential.

Mobile Drum Mix Plant:

The Mobile Drum Mix Plant is a portable, compact unit designed for flexibility and ease of relocation. This type of plant is built on a trailer or skid, allowing it to be transported between different construction sites with minimal setup time. Its features include modular components that can be quickly assembled and disassembled, and the ability to produce asphalt on-site, reducing transportation costs. The primary advantages are its mobility, fast setup, and adaptability to various project locations. Applications include rural road construction, remote infrastructure projects, and situations where frequent site changes are necessary.

Stationary Drum Mix Plant:

The Stationary Drum Mix Plant is a fixed, large-scale plant designed for high-capacity production and long-term use. This type of plant is installed permanently at a single location and is equipped with robust components to handle continuous, high-volume production. Its features include a large drum mixer, efficient heating systems, and advanced control panels for precise operation. The advantages of stationary plants include high production capacity, durability, and the ability to handle large quantities of asphalt efficiently. Applications are typically found in major infrastructure projects, urban development, and any large-scale roadwork where sustained high output is required.

Recycling Drum Mix Plant

The Recycling Drum Mix Plant is designed to blend recycled asphalt pavement (RAP) into new asphalt mixes. It works by blending reclaimed asphalt with new aggregates and bitumen, creating a mix that is both cost-effective and environmentally friendly. This plant reduces the need for fresh materials, lowers production costs, and minimises waste by diverting old asphalt from landfills. It is particularly useful for road repair and maintenance projects where sustainability and cost-efficiency are priorities.

Conclusion

Asphalt drum mix plants comes with continuous mixing capabilities that ensure consistent quality and performance. Their adaptability to various mix designs make them essential for meeting the evolving demands of road construction. With ongoing advancements in technology, asphalt drum mix plants will continue to play a key role in various infrastructure projects.

Image Source: fabhind.com, ashitech.com, coninfra.in, kaushikengineeringworks.com