e trolley is one of the most widespread material handling equipment. It’s simple to use, extremely tough, and safe. And you’ll see dozens of designs to haul heavy items from one place to another. With a trolley built for the task, transporting any type of load will be done efficiently, quickly, and without the risk of injuries or accidents.

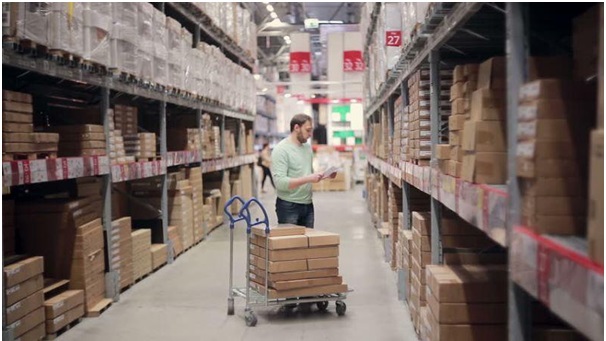

If you’re looking for one for your business, take into account the subtle variations in designs, the use of different materials, safety and ergonomic features that minimise risks and speed up workflow, and the different loads each trolley can take. Also, determine the setting where the trolley will be used. Warehouses and storage facilities are the typical places where heavy-duty trolleys make the most sense, considering they are fast-paced environments that require moving large amounts of goods.

Benefits of Using a Trolley

Increased Safety

Repetitive lifting and carrying heavy items for hours on end can lead to serious strains, muscular and joint damage, and not rarely, life-threatening and permanent injuries. Trolleys, also called trucks, and various other material handling equipment can significantly reduce such occurrences and are recommended for maintaining high work safety standards.

Speed and Improved Productivity

With safety concerns out of the way, the use of a trolley speeds up workflow. Goods get transported and delivered on time, improving overall productivity and speed.

Protection of Goods

Transporting heavy loads to where they are needed is done with the help of stable and secure surfaces, most often platforms or shelves. Goods are secured in that they are prevented from tilting, shifting, and moving around. Of course, the type of trolley should be appropriate for the size and weight of the load.

Simple and Easy to Use

Despite there being dozens of different designs, trucks are simple to use, require minimal employee training, and are also simple to maintain. Heavy-duty designs and materials mean they last for years without the major hiccups and costs that come with more expensive powered lifting equipment.

Easy to Find

If your trolley does show its age, replacements are easy to find. High availability also means lower prices. All sorts of options can be found in general hardware stores, or for more specific tasks, material handling stores are better stocked and with more variety. If you need a trolley for a one-off job, say when moving, you’ll also find options for hire at reasonable prices.

Trolley Types

Platform

This is the largest group and with the most variants. They consist of heavy-duty platform bases atop four wheels or castors. This secures and takes the weight of the load. The platforms can be of different materials depending on the required carrying capacity. Handles are either single affairs (and angled towards the user) or placed at either end. Most are open designs allowing more scope for differently sized goods and equipment, but you’ll also find caged platform trolleys used in transporting smaller items.

Shelf

Similar in design are shelf trucks. These have two or more shelves extending from a frame set on wheels or castors. Transporting smaller items will be done in a more organised fashion thanks to the shelves. Variations can have integrated handles within the frames, or on both sides like platform trolleys. The shelves themselves can be designed as flatbeds, or with side rails and thicker and more durable surfaces (often the top shelves) and double as handy work areas.

Variations are seen in workshops, laundry rooms, offices and schools, airports, hotels, and restaurants for carrying tools, parts, clothing, linen, stationery and supplies, luggage, food, and other items. Baskets, bins, drawers, cabinets and mesh cages make organising and carrying goods easier and safer.

Hand Trucks

These consist of solid bases or platforms and reinforced frames sitting on two wheels. Variations of this design have led to models specialised in hauling appliances, cylinders and drums, and furniture moving sets, among others. Most are designed of durable metals and either polyurethane or rubber wheels depending on where they’re used.

Powered

Powered models have to do with the assisted lifting, lowering, loading, unloading, and transporting of heavy items. Electric motors are powered by one or more batteries. Variations include powered platform trucks that help with transporting speed and safety and scissor lift trucks for lifting and lowering heavy loads to and from heights.

Foldable

When space is tight consider getting a foldable trolley. This doesn’t have to compromise on loading capacity compared to standard variants, and consists of the same durable materials and included safety features. Portability is improved too, and you can take and stow these wherever needed. The only downside is the slightly higher price due to the added convenience.

There are many other trolley types – tote, order picking, construction, cleaning, tool trolleys as well as utility carts, tow tugs, dollies, and more.

Considerations in Choosing What’s Right

Things to consider before buying your first trolley are the specifics of the workplace and the type of load. The workplace will determine the distance users have to cover, the type of surface, gradients and inclines, and where the trolley will be stowed when not in use.

For bigger floorplans get models with durable wheels and also consider powered variants for larger loads. Difficult gradients require integrated brakes, and straps for securing the load. Surfaces that are slippery work best with rubber wheels, whereas concrete floors are more suited to heavy-duty polyurethane castors. Also, have allotted spaces for storing, and consider stackable or foldable models in smaller areas.

For loads, consider how items will be loaded and unloaded, how they will be organised on shelves, platforms, and compartments, the force needed in transporting different loads within the workplace, and any added features that can make the whole process simpler, safer and less physically tasking.

Also take into account factors like overall loading capacity, materials and build quality, wheel and castor types, the required size and ease of use. Loading capacities exceed 100 kilos in smaller and lightweight general-purpose trolleys and go to several thousand kilos in industrial models with assisted power lifting.

Materials vary, from reinforced plastic and wire mesh in models intended for lighter use to aluminium and stainless-steel options with an additional protective coating and paint for more difficult environments and heavier loads. Wheels and castors are also different as mentioned above, with heavy-duty trucks gravitating towards polyurethane or cast iron. Also, castors and wheels should be braked, at least those nearest to the user.

Overall handling depends on the height, width, and overall weight of the trolley, and here you’d want something that is adequate for the load. It is recommended that the height of the trolley doesn’t impede viewing angles as visibility is key. In addition, handles need to be grippy and sourced in the right material to prevent pain or sores from prolonged use.

Cover image source- https://www.mhaproducts.com.au/trolleys/