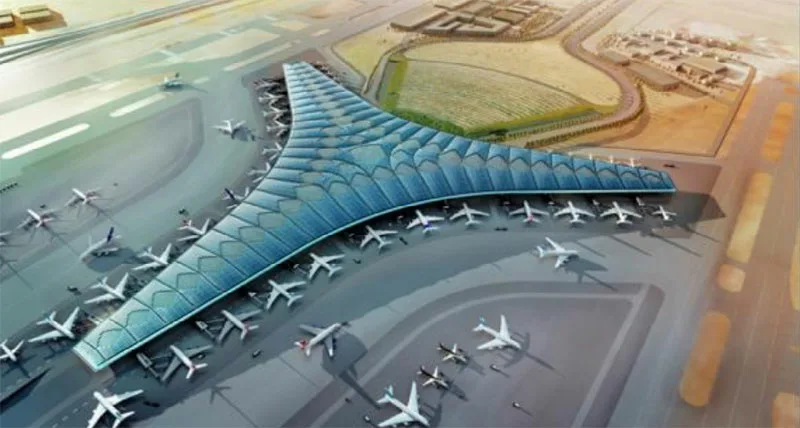

Glass Fiber Reinforced Concrete (GFRC) is a composite material that combines the strength of concrete with the flexibility and lightweight properties of glass fibers. Today, glass fibre reinforced concrete (GFRC) is being used in a wide range of precast concrete applications by designers, architects and engineers because of its flexible ability to meet durable performance and customised design. It offers an ideal solution for airport structures, providing exceptional durability, reduced weight and design versatility. Whether used in the construction of terminal façades, decorative elements, or even air traffic control towers, GFRC’s unique characteristics make it a valuable choice for modern airports seeking both aesthetic appeal and structural integrity in their facilities.

In regard to this, Kuwait International Airport has witnessed a remarkable architectural transformation with the installation of approximately 40,000 square metres of Glass Fiber Reinforced Concrete (GFRC) cladding. This ambitious project, designed by SLABS Engineering, encompasses around 8,000 GFRC panels, each of which presents a unique challenge due to their doubly curved nature.

GFRC Cladding with GFRC Panels

The project has used the concept of GFRC (Glass Fiber Reinforced Concrete) cladding with GFRC panels, a comprehensive architectural approach that leverages the benefits of GFRC material in both cladding and panel applications. It combines the use of GFRC as both the primary cladding material and the prefabricated panels that make up the cladding system. GFRC panels were custom-made to fit the airport’s design requirements and are then assembled on-site to create the final cladding surface.

Use of Doubly Curved Panels

GFRC cladding at Kuwait International Airport, particularly the doubly curved panels, represent a sophisticated blend of architectural design and structural engineering. Doubly curved panels, chosen primarily for their aesthetic qualities, convey a sense of elegance, sophistication, and modernity in architectural design. In airport welcomers areas, these panels will contribute to a contemporary and welcoming atmosphere, making a positive first impression on travellers.

Beyond aesthetics, doubly curved panels will serve functional purposes. They will provide shade, shelter from the elements, or acoustic insulation, enhancing the comfort and usability of the welcomers area. Doubly curved panels were customized to fit the specific design requirements of the airport welcomers’ area. The curvature of these panels can interact with natural and artificial lighting, creating dynamic lighting effects that add to the ambiance of the welcomers area.

GFRC Panelling in the welcomers Area and Waterfall Baggage Reclaim Area

The work executed in the welcomers area and waterfall baggage reclaim area involves several critical tasks aimed at achieving a visually appealing and structurally sound environment while adhering to specific client requirements. The key works included;

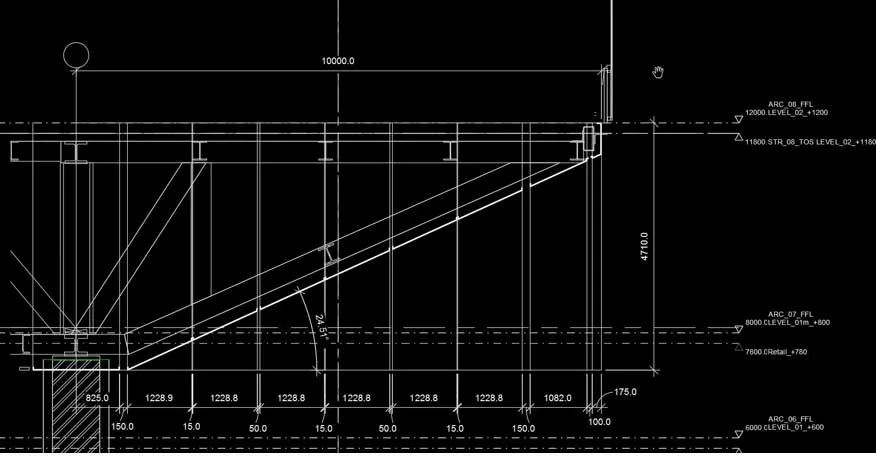

1. Ensuring Repeatability of Elements: This task focuses on creating uniformity and consistency in the design and installation of cladding elements within the welcomers area and waterfall baggage reclaim areas. Repeatability ensures that the same design elements or panels are replicated accurately throughout the space. This uniformity enhances the aesthetic appeal of the area and creates a sense of cohesion.

2. Maintaining Gaps Between Panels in the Cross Section: The gaps between panels in the cross section are crucial for several reasons. First, they allow for thermal expansion and contraction of materials, preventing structural issues that can arise due to temperature fluctuations. Second, these gaps can be designed to align with the overall aesthetic vision of the welcomers area and waterfall baggage reclaim area. To meet the client’s requirements, maintaining specific gap dimensions is essential for both functional and design-related purposes.

3. Maintaining Adjacent Gaps Between Panels Along the Curvature: In areas where the cladding follows a curved or non-linear path, such as the curvature of a wall, maintaining consistent gaps between adjacent panels is challenging but essential. These gaps should adhere to precise measurements, such as 10 millimetres +/- 2 millimetres. This level of precision ensures that the cladding maintains a seamless and visually appealing appearance, especially in areas where design continuity is critical.

4. Identifying Suitable Panel Geometries After Panelization: Panelization involves the process of breaking down the overall cladding design into individual panels or modules that can be fabricated off-site and later assembled on-site. Identifying suitable panel geometries means selecting panel shapes and sizes that not only meet construction requirements but also adhere to the repeatability of elements, gap maintenance, and curvature alignment criteria outlined in points 1, 2, and 3.

The work executed in the welcomers area and waterfall baggage reclaim area involved meticulous planning and attention to detail to achieve a harmonious and functional cladding design. It required maintaining consistent design elements, adhering to specific gap dimensions, ensuring precise alignment along curves, and selecting panel geometries that meet both construction and design criteria.

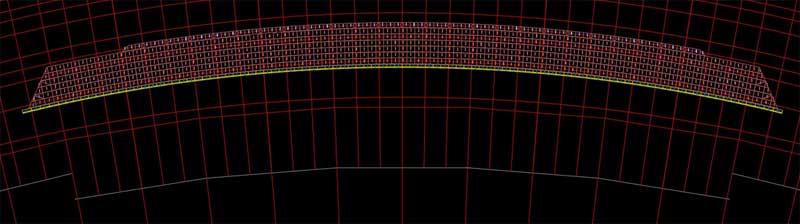

GFRC Panelization analysis of airport’s welcomers area

In the analysis of the panel layout in the airport’s welcomers area several key points were considered:

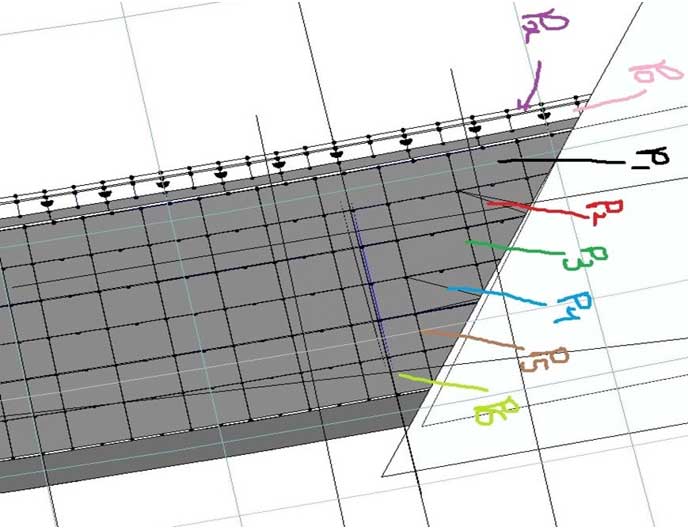

1. Subgrid Composition: The guidelines specify that each subgrid is composed of three panels, and for the sake of illustration, let’s say they are of type P1. This means that within each subgrid, you will have three panels that are all of the same type.

2. Objective of Panel Placement: The primary goal is to arrange similar panels within the same subgrid. In this case, the focus is on ensuring that all three panels within a subgrid are of type P1. This creates a visually consistent and organized look within each subgrid.

3. Tolerance for Length Matching: To accommodate potential variations in the panels’ dimensions, the guidelines state that if the length of a panel falls within a range of +/- 2 millimeters of another panel, they are considered to be the same unique panel. This tolerance allows for minor variations in panel length daue to manufacturing or installation processes.

These guidelines were used to achieve uniformity and consistency in the appearance of each subgrid by grouping together panels of the same type (P1 in this example). They also recognize that small variations in panel length can occur, so panels falling within the +/- 2 millimeter range are treated as identical to maintain a cohesive and aesthetically pleasing design in the welcomers area of the airport.

Outcome of Panelization Analysis – Welcomers Area:

1. Zone Identification:

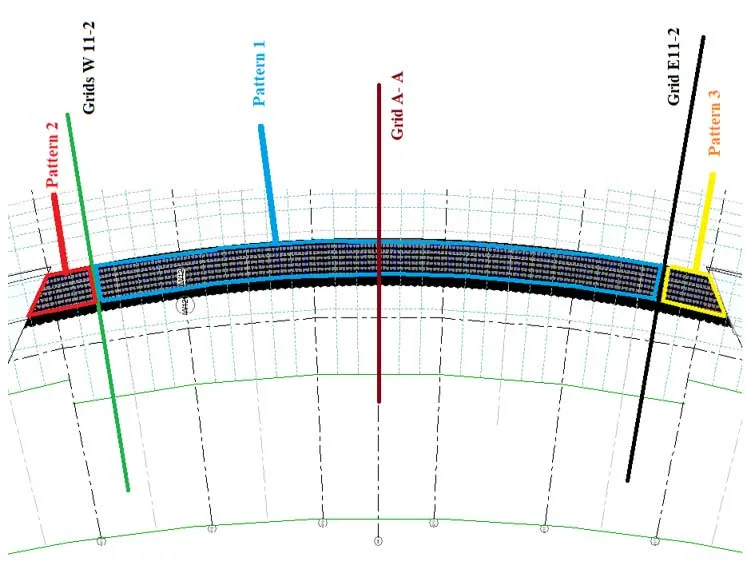

The analysis resulted in the identification of three distinct zones within the welcomers area:

Pattern 1:

- In this pattern, the panels in each row remain the same, for example, panels labeled as P1 and P2. This means that when you look at any given row within Pattern 1, you’ll see a consistent arrangement of panels, maintaining a specific visual pattern.

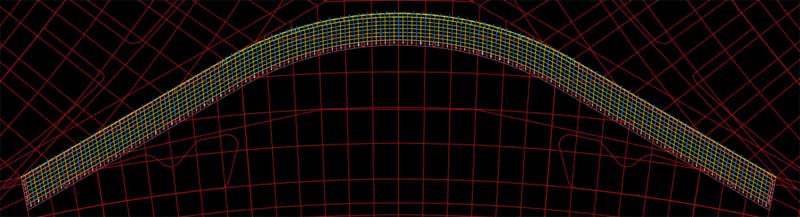

Pattern 2:

- Panels within Pattern 2 are identified as typical, and they are grouped wherever they are geometrically identical. However, corner and edge pieces within this pattern are unique due to their specific shapes. This suggests that while the majority of panels in Pattern 2 have a repeating geometry, there are specialized corner and edge pieces that deviate from this repetition.

Pattern 3:

- Similar to Pattern 2, panels within Pattern 3 are identified as typical, and they are grouped wherever they are geometrically identical. As with Pattern 2, corner and edge pieces within this pattern are unique due to their shapes. This indicates that there is a repeated geometry in most panels in Pattern 3, with exceptions for corner and edge configurations.

These patterns provide a structured understanding of how panels are arranged and repeated within the welcomers area. Pattern 1 represents rows with consistent panel types, Pattern 2 and Pattern 3 emphasize geometrically identical panels with unique corner and edge pieces, adding diversity to the visual design of the area. These findings helped maintain a cohesive and aesthetically pleasing design while accommodating variations in panel shapes and layouts.

GFRC Panelization Analysis of the Airport’s Baggage Reclaim Waterfall Area

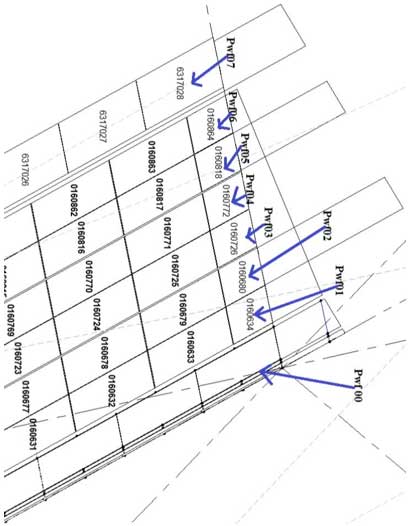

In the analysis of the panel layout in the airport’s baggage reclaim waterfall area, several key points were considered:

1. Subgrid Composition: Each subgrid is composed of three panels, all of which are of type P1, as an example. This means that within each subgrid, there are three identical panels of type P1.

2. Objective of Panel Placement: The primary objective was to ensure that similar panels are placed within the same subgrid. This arrangement helps create a visually cohesive and organized appearance in the waterfall area.

3. Tolerance for Length Matching: To accommodate potential variations in panel dimensions, a tolerance range of +/- 2 millimeters was defined. If the length of a panel falls within this range of another panel, they are considered to be the same unique panel. This tolerance allows for minor variations in panel length due to manufacturing or installation processes.

4. Challenges in Achieving Repeatability: Given that each panel is adjacent to each other and has a length of around 10 meters +/-, achieving a high level of repeatability in the waterfall area can be challenging. The length of the panels and their adjacency limits the possibilities for variation.

5. Symmetry: It’s important to note that there is symmetry about the major external Axis grid AA. This symmetry plays a significant role in the panel layout, influencing how panels are placed and repeated in the area.

6. Repetition of Panels: Due to the symmetry mentioned earlier, each panel repeats approximately two times in this area. This repetition helps maintain a sense of balance and uniformity in the design.

The panelization analysis aimed to ensure that panels of the same type were grouped together within subgrids while considering the challenges posed by panel length and adjacency. The symmetry around Axis grid AA allowed for a certain level of repetition, contributing to the overall aesthetic and functional design of the baggage reclaim waterfall area in the airport.

Outcome of Panelization Analysis for Baggage Reclaim Waterfall Area

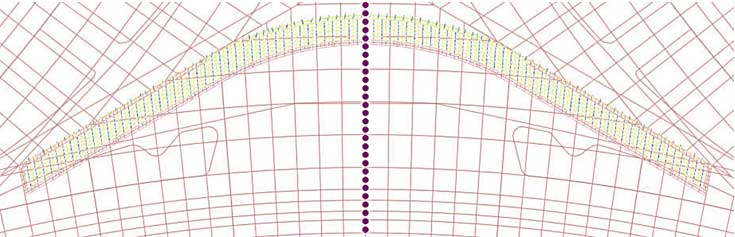

The panelization analysis of the baggage reclaim waterfall area has revealed a specific outcome:

1. Repetition Within the Zone: In the context of the entire baggage reclaim waterfall area, each panel will repeat approximately two times. This means that you will observe the same panel design appearing twice within this zone. This repetition helps establish a sense of consistency and visual continuity, contributing to the overall aesthetics.

2. Production Perspective: From a production perspective, these panels may be considered as distinct or different entities. This is because they are often mirror images along the central axis. While visually they appear the same due to the repetition, in terms of manufacturing or procurement, they may be treated as unique panels. This distinction is important for logistical and production considerations.

In essence, while the panels repeat in terms of appearance and visual continuity within the baggage reclaim waterfall area, their mirroring along the central axis may necessitate treating them as distinct units for production and procurement purposes. This duality allows for both visual consistency and practical production efficiency in the design of the area.

Conclusion

Kuwait International Airport has achieved a remarkable synergy between artistic vision and engineering precision through its strategic use of Glass Fiber Reinforced Concrete (GFRC) cladding and meticulous panelization analysis. This ambitious project, designed by SLABS Engineering Private Limited, has breathed new life into the airport’s aesthetic appeal while maintaining structural integrity. The airport now stands as a shining example of the transformative potential of deliberate design, adherence to guidelines, and the flawless execution of a grand architectural vision. It sets an exceptional standard for future airport projects, both in terms of aesthetics and functionality.

About SLABS

SLABS Engineering Private Limited (SLABS) has been synonymous with delivering top-notch engineering and architectural solutions since its establishment in 2014. Headquartered in Pune, the company excels in taking on challenging projects and offering a diverse range of services that cater to the genuine needs of clients, both in the public and private sectors.

The name of their business, SLABS, derives from engineering terminology, signifying a solid foundation, and also doubles as “LAB,” emphasizing that their solutions are thoroughly research-based and known for their exceptional accuracy, a commitment they uphold for their clients.

The company specializes in offering comprehensive architectural and structural engineering services spanning a diverse array of building types, encompassing residential, commercial, office, educational, cultural, recreational, hospitality, and healthcare facilities. Their core values center around the pursuit of design excellence and aesthetic quality, all while maintaining a keen focus on cost reduction strategies during both the design and construction phases.

Their service also encompass MEP (Mechanical, Electrical, and Plumbing) design, which incorporates cutting-edge engineering advancements and energy-saving techniques to craft comfortable interior environments that meet the highest standards.

SLABS Engineering Private Limited

Level 9, Tower 2, World Trade Center, Opp. EON Free Zone, Kharadi, Pune – 411 014 India.

For more details visit- slabsc.com