Geosynthetics products have the characteristics of so-called tailor-made materials, which are known to function for specific applications. The long-term performance of these products has a close relationship with the stability of the applied structure and practical applications such as continuous new methods and new technology. As the demand and necessity for high-performance products gradually increase, composite products, environment-friendly products, environment adaptive products, hybrid, or smart products are being applied in infrastructure projects. Most geosynthetics products are made from synthetic polymers of polypropylene, polyester, or polyethylene.

There are different types of geosynthetics products that are used for ground performance improvement. Each of them is explained below.

Geotextiles for ground performance improvement

Geotextiles are a kind of geosynthetic material that has become more and more popular over the past fifteen years. The material owes its success in more than 80 applications to a large extent to its resistance to biodegradation. Geotextiles are indeed textiles, however not in the traditional sense of the word. They are no natural materials like cotton, wool or silk. Geotextiles are synthetic fibers that can be made into a flexible, porous, nonwoven needle felt fabric. They are porous to water flow, to a varying degree. Geotextiles are porous to liquid flow across their manufactured plane and also within their thickness, but to a widely varying degree. There are at least 100 specific application areas for geotextiles that have been developed; however, the fabric always performs at least one of four discrete functions: separation, reinforcement, filtration, and/or drainage. Geotextiles form one of the two largest groups of geosynthetics. They are textiles consisting of synthetic fibers rather than natural ones such as cotton, wool, or silk. This makes them less susceptible to biodegradation. These synthetic fibers are made into flexible, porous fabrics by standard weaving machinery or are matted together in a random non-woven manner. Some are also knitted.

Geogrid for ground performance improvement

Geogrid is a category of geosynthetic material that can be used to provide the functions of reinforcement, stabilization, and filtration. The main function of Geogrids is reinforcement. Depending on the application under consideration, Reinforcement could either be uniaxial (strength in one direction) or biaxial (strength in all directions). They are graded by several performance properties for instance tensile strength, junction efficiency, or trade name. One of the most common applications for a geogrid is for the stabilization of poor soils during site work. Construction projects often encounter weak, wet soils that are not suitable to build on. Conventional approaches to this problem would be to remove and replace (over-excavation) the bad material, place a thick layer of aggregate, or other granular material, as a bridge layer, or chemically treat the soil to improve its strength. Geogrids provide a simpler, more cost-effective solution using the functions of filtration and stabilization.

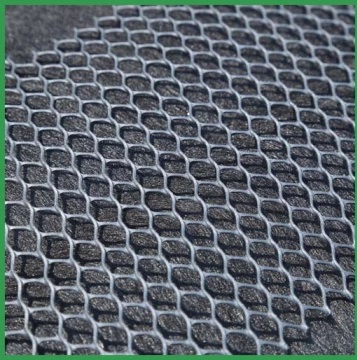

Geonet for ground performance improvement

A geonet is a geosynthetic material consisting of integrally connected parallel sets of ribs overlying similar sets at various angles for in-plane drainage of liquids or gases. Geonets may be used as either liquid or gas collectors. The typical applications for these products are in all applications that require drainage/collection of gas and leachates (mining and landfill) and filtration of sediments contained within these liquids. Transnet® is specially formulated to allow for use in high load applications such as landfill cells and where compression resistance is critical. Geonets are used at road construction, their restoration and repair to improve the road surface quality, decrease washboard formation, primary and secondary reflected cracking. Geonets are a mesh structure consisting of overlapping threads/bands (from 3 to 15 mm) at a permanent angle (60-90°). This creates equal holes with a width from 10 to 200 mm. They are obtained by press forming of thermoplastic polymer (usually it is high strength polyethylene) or welding of threads/bands.

Geocomposites for ground performance improvement

Geocomposites are multi-layered combinations of geosynthetics. These combinations provide benefits over individual layers by enhancing functions, increasing interface friction angles, and speed of installation. With careful design, they can provide drainage, protection, reinforcement, filtration and barrier functions while replacing expensive and scarce mineral resources. A geocomposite consists of a combination of geotextiles, geogrids, geonets and/or geomembranes in a factory-fabricated unit. Also, anyone of these four materials can be combined with another synthetic material (e.g., deformed plastic sheets or steel cables) or even with the soil. For example, a geonet or geospacer with geotextiles on both surfaces and a GCL consisting of a geotextile/bentonite/geotextile sandwich are both geocomposites. This specific category brings out the best creative efforts of the engineer and manufacturer. The application areas are numerous and constantly growing. The major functions encompass the entire range of functions listed for geosynthetics discussed previously: separation, reinforcement, filtration, drainage, and containment.

Geomembranes for ground performance improvement

Geomembranes are being used in environmental, hydraulic, transportation, and oil and gas applications as well as the waste industry. The most common type is the continuous polymeric sheets. A geomembrane is a very low permeability synthetic membrane liner or barrier used with any geotechnical engineering related material to control fluid (or gas) migration in a human-made project, structure, or system. Geomembranes are made from relatively thin continuous polymeric sheets, but they can also be made from the impregnation of geotextiles with asphalt, elastomer or polymer sprays, or as multilayered bitumen geocomposites. Continuous polymer sheet geomembranes are, by far, the most common.

Geosynthetic clay liners for ground performance improvement

Geosynthetic clay liners (GCLs) are factory manufactured hydraulic barriers consisting of a layer of bentonite or other very low-permeability material supported by geotextiles and/or geomembranes, mechanically held together by needling, stitching, or chemical adhesives. Due to environmental laws, any seepage from landfills must be collected and properly disposed of, otherwise, contamination of the surrounding ground water could cause major environmental and/or ecological problems. The lower the hydraulic conductivity the more effective the GCL will be at retaining seepage inside of the landfill. Bentonite composed predominantly (>70%) of montmorillonite or other expansive clays, are preferred and most commonly used in GCLs. A general GCL construction would consist of two layers of geosynthetics stitched together enclosing a layer of natural or processed sodium bentonite. Typically, woven and/or non-woven textile geosynthetics are used, however polyethylene or geomembrane layers or geogrid geotextiles materials have also been incorporated into the design or in place of a textile layer to increase strength.

Turf Reinforcement Mats for ground performance improvement

Turf Reinforcement Mats (TRM) is the ideal product for long term erosion protection on slopes and in channels. They are used in applications where two to three times the normal erosion protection is necessary. Made of flexible, three-dimensional polypropylene, TRMs can mold to the vulnerable area and are anchored to the soil to promote the growth of vegetation. Use TRMs for a permanent solution for erosion control while allowing for mature plant growth. TRMs are the preferred environmental alternative to hard armor. Applications include protection in drainage ditches, open channels, steep slopes and detention basins. It is a permanent, cost-effective and environmentally friendly alternative to hard armor erosion protection solutions such as concrete and rips rap. UV and chemical resistant synthetic polyolefins are manufactured to create a flexible three-dimensional matrix.

Geocells for ground performance improvement

Geocells mechanically confine soil based on cell geometry. Upon loading, every polymer material will elongate (creep) over time. Geocells (also known as Cellular Confinement Systems) are three-dimensional honeycombed cellular structures that form a confinement system when infilled with compacted soil. Extruded from polymeric materials into strips welded together ultrasonically in series, the strips are expanded to form the stiff (and typically textured and perforated) walls of a flexible 3D cellular mattress. Infilled with soil, a new composite entity is created from the cell-soil interactions. The cellular confinement reduces the lateral movement of soil particles, thereby maintaining compaction and forms a stiffened mattress that distributes loads over a wider area. Traditionally used in slope protection and earth retention applications, geocells made from advanced polymers are being increasingly adopted for long-term road and rail load support. Much larger geocells are also made from stiff geotextiles sewn into similar, but larger, unit cells that are used for protection bunkers and walls.

Conclusion

The manufactured quality control of geosynthetics products in a controlled factory environment is a great advantage over outdoor soil and rock construction. Most factories are ISO 9000 certified and have their own in-house quality programs as well. The low thickness of geosynthetics, as compared to their natural soil counterparts, is an advantage insofar as lightweight on the subgrade, less airspace used, and avoidance of quarried sand, gravel, and clay soil materials. It is important to choose the right product with the right quality.

Img Source : in.pinterest.com,huataogroup.com,geo-synthetics.com ,alibaba.com, geotechpedia.com,geoturf.com,terramgeosynthetics.com,geplus.co.uk,nilex.com