Fall arrest systems are designed to protect workers from serious injury when working at heights by preventing them from hitting the ground or lower levels in case of accidental fall. The system operates on the principle of distributing the forces of a fall across the body to a secure anchor point to arrest the fall safely. Its importance lies in its ability to reduce the impact force experienced by a worker during a fall, thereby significantly decreasing the risk of injury. Fall arrest systems are essential in maintaining compliance with occupational safety regulations and ensuring worker safety in industries like construction, maintenance etc. to prevent workplace accidents and fatalities.

Where are fall arrest systems used?

1. Scaffolding: During the construction, maintenance, or repair of buildings, workers on scaffolding need fall arrest systems to protect against falls from heights.

2. Rooftop Work: When installing or repairing roofing systems, workers are at risk of falling from the edges or during roof access, making fall arrest systems necessary.

3. Structural Steel Erection: Workers assembling and welding structural steel beams and columns at elevated levels require fall arrest systems for protection against falls.

4. Elevated Platforms and Lifts: Using aerial work platforms, boom lifts, or cherry pickers for tasks like installing windows or maintaining infrastructure necessitates fall arrest systems for safe operation.

5. Excavations and Trenches: While working on the edges of deep excavations or trenches, fall arrest systems help prevent accidents due to collapse or slips.

6. Formwork and Shoring: Workers involved in setting up and dismantling formwork or shoring systems for concrete structures are at risk of falling, requiring appropriate fall arrest measures.

7. Bridges and Overpasses: During the construction or maintenance of bridges and overpasses, workers working on beams, supports, or scaffolding need fall arrest systems for safety.

8. Tower Construction: In building or maintaining communication towers, electrical towers, or observation towers, fall arrest systems are crucial for preventing accidents from height.

Advantages of fall arrests systems

- Limits fall distance to reduce impact injuries.

- Incorporates energy-absorbing components to minimise fall forces.

- Includes certified anchor points for secure connections.

- Distributes fall forces over the body using full-body harnesses.

- Features automatic locking mechanisms in SRLs to arrest falls.

- Uses fall-detection and braking systems in fall arrest blocks.

- Offers adjustable configurations for continuous fall protection.

- Provides secure, continuous protection with horizontal lifelines.

Different types of fall arrest systems

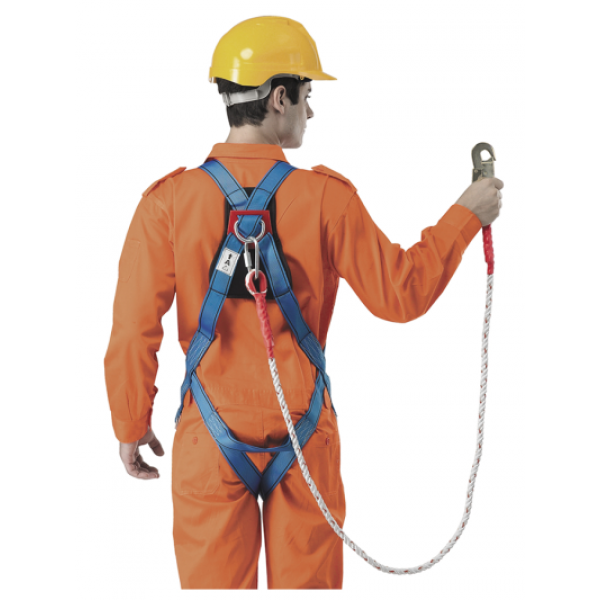

1. Full-Body Harnesses

Full-body harnesses are integral components of fall arrest systems designed to provide comprehensive safety for workers exposed to fall hazards. The harness consists of multiple straps that wrap around the worker’s shoulders, chest, and thighs, distributing fall forces over a larger surface area to minimize injury. A key feature of the harness is the D-ring, usually located on the back, which serves as the connection point for the lanyard or other fall arrest devices. Full-body harnesses are essential in various construction tasks, including working on scaffolding, roofs, and elevated platforms. They are designed for comfort and adjustability to fit different body types and work conditions. The harness’s importance lies in its ability to effectively distribute the forces experienced during a fall, reducing the risk of injury and providing a secure connection to other fall protection equipment.

2. Lanyards

Lanyards are versatile components of fall arrest systems that connect a worker’s harness to a secure anchor point. They are typically made from durable materials such as nylon or polyester and come in various configurations, including shock-absorbing lanyards and double-leg lanyards. Shock-absorbing lanyards contain a device that slows down the fall by elongating during the fall, which reduces the impact forces on the worker’s body. Double-leg lanyards feature two separate lines, allowing workers to remain attached to an anchor point while moving between two different points. The importance of lanyards lies in their role as a link between the worker and the fall arrest system’s anchor point, providing crucial protection by preventing falls from reaching hazardous levels and complying with safety regulations.

3. Self-Retracting Lifelines (SRLs)

Self-retracting lifelines (SRLs) are advanced fall protection devices that automatically extend and retract as a worker moves. These devices use a spring-loaded mechanism to manage the length of the lifeline and a braking system to arrest falls. SRLs can be equipped with either cable or webbing, with cables being more durable and webbing being more flexible and lightweight. The main advantage of SRLs is their ability to offer dynamic fall protection with minimal slack, which allows workers to move freely while ensuring that the system will lock in the event of a fall. The importance of SRLs lies in their ability to limit the distance of the fall and reduce the impact forces on the worker, thereby enhancing safety and improving compliance with occupational safety standards.

4. Fall Arrest Blocks

Fall arrest blocks are compact and robust fall protection devices that incorporate a retractable lifeline and a braking mechanism into a single unit. These devices are similar to SRLs but are often more streamlined and portable, making them ideal for applications where space is limited or where frequent movement is required. Fall arrest blocks come with either cable or webbing lifelines, and their internal braking system locks the line in the event of a fall to stop the worker’s descent. The importance of fall arrest blocks lies in their ability to provide immediate fall protection with a simple and effective design, offering convenience for workers engaged in tasks such as tower maintenance or bridge construction.

5. Anchor Points

Anchor points are essential elements of fall arrest systems that provide a secure and reliable connection between the worker’s fall protection gear and a stable structure. They can be permanent, such as those installed during building construction, or temporary, used for specific projects and removed after task completion. Anchor points come in various forms, including roof anchors, wall anchors, and beam anchors, each designed to support the forces generated during a fall. The significance of anchor points lies in their role as the foundation for the fall arrest system, ensuring that the harness and lanyard are securely attached to a structure capable of withstanding fall forces. Properly installed and maintained anchor points are crucial for the effectiveness of the entire fall arrest system and for meeting safety regulations.

6. Vertical Lifelines

Vertical lifelines are fall protection systems that provide a secure climbing or descending path for workers. These systems consist of a rope or cable that runs vertically from the ground to an elevated work area, and a climbing device or fall arrest device that moves along the lifeline. The climbing device locks onto the lifeline during a fall, effectively stopping the worker’s descent. Vertical lifelines are often used in situations where workers need to ascend or descend significant heights, such as during the construction of tall structures or for tower maintenance. The importance of vertical lifelines lies in their ability to offer continuous fall protection during climbing or descending operations, ensuring worker safety and adherence to safety protocols.

7. Horizontal Lifelines

Horizontal lifelines are fall protection systems designed for workers who need to move horizontally across elevated areas. These systems consist of a rope or cable stretched between two or more anchor points, with workers secured by a harness and a fall protection device that slides along the lifeline. Horizontal lifelines are particularly useful for tasks such as roof maintenance or bridge inspections where workers need to move across large spans. The main benefit of horizontal lifelines is their ability to provide fall protection across extended horizontal distances, allowing workers to perform tasks safely while moving along a defined path. These systems must be properly designed and installed to ensure that they can support the forces involved during a fall.

8. Roof Anchors

Roof anchors are specialized fall protection devices attached to the roof structure to secure workers’ harnesses and lanyards. These anchors can be permanent fixtures installed as part of the building’s design or temporary installations used for specific tasks and then removed. Roof anchors come in various forms, including fixed anchors, sloped roof anchors, and roof-mounted anchors, each tailored to different types of roofs and applications. The importance of roof anchors lies in their ability to provide a secure attachment point for fall protection equipment during roof maintenance or construction. Properly installed roof anchors are essential for ensuring that the fall arrest system functions effectively and meets safety regulations.

Guidelines for fall arrest systems

- Identify potential fall risks like height, surface conditions, and obstacles.

- Choose harnesses, lanyards, SRLs, and anchors appropriate for the hazards identified.

- Follow standards such as OSHA 1926.501 or EN 361 for fall protection systems.

- Follow detailed installation procedures for proper setup and effectiveness.

- Use only certified and well-maintained fall arrest equipment.

- Provide training on equipment use, inspection, and emergency response.

- Create a plan detailing rescue procedures, equipment, and emergency contacts.

- Check for damage or wear on harnesses, lanyards, and anchors before use.

- Keep records of equipment inspections, maintenance, and worker training.

- Regularly review and update fall protection procedures and plans.

Conclusion

A fall arrest system is essential for protecting workers from falls and preventing serious injuries in construction and infrastructure projects. By distributing fall forces, ensuring compliance with safety standards, and providing critical safety equipment such as harnesses, lanyards, and anchor points, these systems safeguard workers during high-risk tasks. Effective fall arrest systems are not only a regulatory requirement but also a key component in maintaining a safe work environment. Following best practices for equipment selection, installation, training, and regular inspections ensures that these systems perform optimally and contribute to a culture of workplac