Scaffold is a temporary elevated platform and its supporting structure used for supporting workmen, materials or both” in the construction or repair of buildings and other large structural maintenance.

Scaffold Selection

Scaffolding depends on selection of the right system for the job to use in Safe and Efficient way. If the selected scaffold is unsuited for the task, or if necessary components are not available, the assemble and use of the same is not acceptable.

Selection of scaffolding and related components requires an understanding of site conditions and the works to be undertaken.

Employers must consider the following below points:

- The weight of the workers, tools, materials and equipment’s to be carried by the scaffold (safe work load)

- Site conditions (interior, exterior, backfill, concrete floors, type and conditions of wall, access for the equipment’s, variations in elevations, anchorage points, etc.)

- Height to which or where the scaffold may be erected(overhead powerlines, tie backs)

- Type of work that will be done from the scaffold (masonry work, sandblasting, painting, metal siding, mechanical installation, suspended ceiling installation)

- Duration of work

- Weather conditions, including wind and ice build–up

- Requirements for pedestrian traffic through and under the scaffold area,

- Means of access to the scaffold

- Configuration of the building or structure being worked on

- Special assembly or dismantling circumstance

- Temporary fencing to limit unapproved access

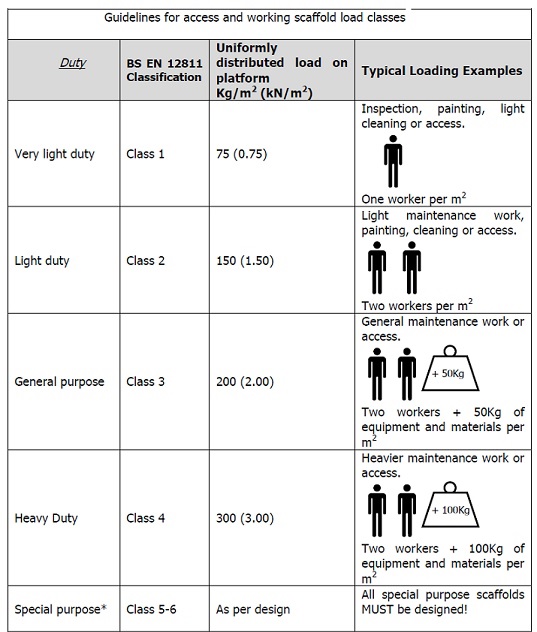

Scaffold Classification As per BS EN 12811

| Load Class | Maximum bay length | Safe Working load Kn/m² | Maximum transom spacing or scaffold width |

|---|---|---|---|

| Very light duty | 2.7m | 0.75Kn | 1.2m |

| Light duty | 2.4m | 1.5Kn | 1.2m |

| General purpose | 2.1m | 2.0Kn | 1.2m |

| Heavy duty | 1.8m | 3.0Kn | 0.9m |

| Special purpose | Needs to be designed | Needs to be designed | Needs to be designed |

Scaffolds are classified by type according to their use

Each scaffold has a set maximum loading, which determines the maximum bay centre as follows below

| Use of scaffold | Types of scaffold | Minimum Numbers of boards required (Centres of standards) | Maximum number of working platforms | Typical load examples per bay | Maximum bay Length | Platform loadings Kg/m2 |

|---|---|---|---|---|---|---|

| Inspection Painting Light access | Very light duty Independent | 3(0.77m) | 1Level | No Materials 1 operatives+ tools | 2.7m | 75 |

| Inspection Painting cleaning | Light duty Birdcage | Fully boarded | 1Level | No Materials 1 operatives+ tools | 2.5mx1.2m | 75 |

| Plastering Painting Cleaning | Light duty Independent | 4(1.0m) | 2 Level(1st level 100% another level 50%) | 2 Operatives +175kg materials | 2.4m | 150 |

| Building work Lightbrick work | General purpose Independent | 5(1.2m) | 2Level(1st level 100% another level 50%) | 1 Operatives +350kg materials | 2.1m | 200 |

| Brickwork heavy Cladding | Heavy duty Independent | 5(1.2m) | 2Level(1st level 100% another level 50%) | 2 Operatives +250kg materials | 2.0m | 250 |

| Masonry work Concrete Blockwork | Special or Masonry Independent | 6(1.5m) | 1-100%+1-50% | 1 Operatives +400kg materials | 1.8m | 300 |

| New brick work | Putlog scaffold | 5(1.2m) | 1 | 1 Operatives +140 bricks | 2.0m | 250 |

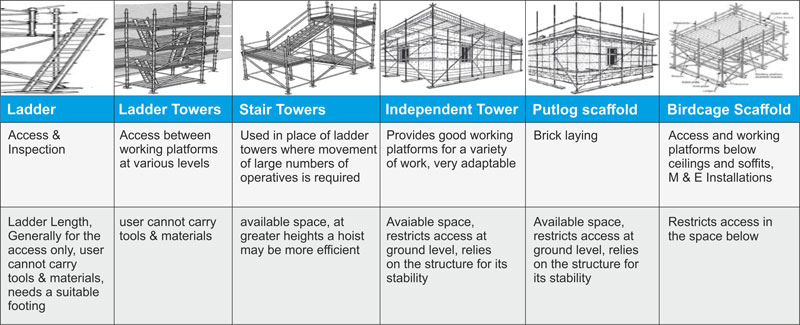

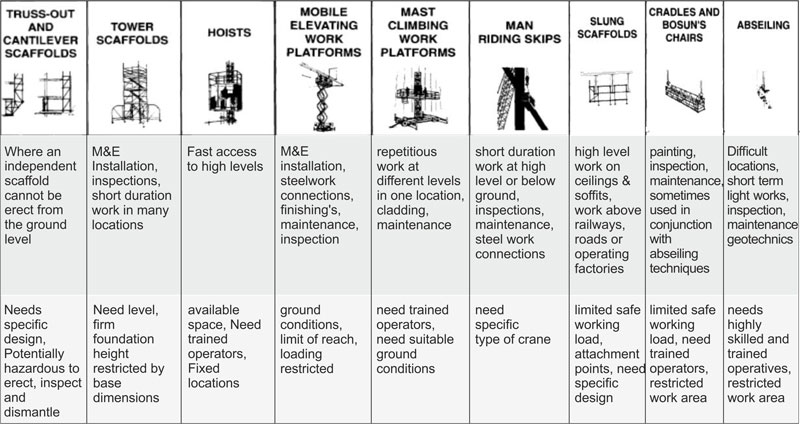

Access to Heights

- Ladders

- Scaffold

- Towers Hoists

- Mobile Elevating Work

- Platforms Mast Climbing Work

- Platforms Man-Riding Skips

Access from Heights

- Suspended Access

- Abseiling

Special Requirements

- Access to below Ground

- Access over Water

- Segregation of workers from Machinery & Plant

- Work Adjacent to Roads & Railways

Systems scaffolding

Steel Based Scaffolds

- Tube & clamps

- Frame type

- Wedge lock or Kwik stage

- Cuplock

- Ringlock

- Aluminium framed towers

System Scaffolding Configuration & Applications

- Facades

- Curved & Circular(Circular tanks)

- Stairway Towers

- Cantilever scaffold

- Drop Lift scaffold

- Mobile tower, Modular Mobile Gantry Scaffold

- Independent tied Scaffold, Static or Independent towers, Free Standing Independent tower

- Interior Access Birdcage tower

- Loading Towers

- Suspended scaffold, Suspended or Hanging scaffold

- Access Towers

- Industrial / Petrochemical

- Civil Construction Activities-Rebar, Plastering, Painting& Finishing, False ceiling-M&E Works

- Refurbishment

- Commercial-Events / Stages / Advertisement Towers

- Cladding

- Roof Works

Access to Height & Access from Height

Scaffold load carrying capacity

Its depends on the grade of the steel as defined below

Scaffold tube 48.3mm dia

3.2mm thickness

| Grade of steel | 40(A,B,C) | 43(A,B,C) | 50(A,B,C) |

|---|---|---|---|

| Yield strength Approx. | 235 | 275 | 355 |

| Leg load carrying capacity Approx. | 2.5KN | 3.5KN | 5.5KN |

A-Light Duty B-Medium Duty C-Heavy Duty

- Ship Building

- Flight Maintenance

- Temporary seating & Staging or Stadiums

Conclusion

Adopting an electronic scaffolding management system can substantially contribute to the goal of operating excellence while reducing operational costs relatively well.

- In summary, benefits are based on more effective & efficient administration systems to enforce procedure prior to, during & after work as well as identifying key areas of improvement due to better analytical results.

We will discuss more scaffolding systems in an upcoming article series.