In the Indian construction industry, ensuring timely project completion is a growing concern. The sector frequently faces delays that not only disrupt project timelines but also escalate costs and impact overall efficiency. This challenge is highlighted by the significant prevalence of time overruns, which affect a substantial portion of construction projects. Addressing these issues requires a deep understanding of the factors contributing to delays and a commitment to robust project management practices.

The time overruns affect around 54% of projects, with delays ranging from several months to an extreme 252 months (21 years). This underscores the critical importance of effective project management. The primary causes of these delays are often rooted in inadequate planning and improper scheduling.

Effective planning is essential for mapping out the most efficient sequence of tasks and anticipating potential challenges and resource needs, which helps in setting a clear project path. Insufficient planning can lead to unexpected issues and inefficiencies, contributing to delays and increased costs. On the other hand, scheduling involves determining the timing and sequence of tasks to align with the overall project timeline. Proper scheduling ensures that activities are executed in the correct order and helps avoid conflicts and delays. Poor scheduling can result in misalignment of tasks and resources, further prolonging the project.

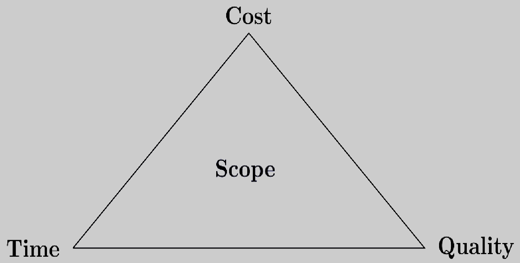

The impact of scheduling issues can be visualized through the Project Triangle, also known as the Triple Constraints or Iron Triangle. This model illustrates the three critical constraints in project management:

- Time: The total duration needed to complete the project.

- Cost: The budget allocated for the project.

- Scope: The specific objectives and deliverables of the project.

The Project Triangle demonstrates that changes in one constraint affect the other two. For instance, extending the project timeline (Time) can increase costs or require a reduction in project scope to remain within budget. Recognizing this interdependence underscores the importance of balancing time, cost, and scope to prevent delays and ensure project success.

Construction Scheduling Methods

The following are some of the methods used for scheduling construction projects.

- Gantt Chart – Horizontal Bar Graphs and Timelines

- Project Network Diagramming

- Critical Path Method (CPM)

- Program Evaluation and Review Techniques (PERT)

- Precedence Diagramming Method (PDM)

- Linear Scheduling

- Stochastic Network – Graphical Evaluation and Review Technique (GERT)

- Repetitive Scheduling (RS) and Short-Interval Scheduling (SIS)

In this paper we have focused on Critical Path Method (CPM) and Program Evaluation and Review Techniques (PERT).

Critical Path Method (CPM)

The Critical Path Method (CPM) was first developed in 1957 by Morgan R. Walker from the Engineering Services Division of DuPont and James E. Kelly Jr. of Remington Rand. It emerged as a powerful project management tool, particularly suited for projects with well-defined tasks and predictable timelines.

Key Features of CPM:

- Activity-Oriented Networks: CPM is fundamentally activity-oriented, meaning that it focuses on the sequencing and scheduling of project activities. The entire project is broken down into individual tasks, each of which must be completed for the project to progress.

- Work Breakdown Structure (WBS): The project activities are categorized using a Work Breakdown Structure (WBS), which is a hierarchical decomposition of the total scope of work to accomplish the project objectives. This categorization is visualized through a technique called Arrow Diagramming, where each arrow represents an activity.

- Duration and Critical Path Determination:

- Activity Duration: The duration of each task is estimated, and critical activities (those with the longest durations) are identified.

- Critical Path: The critical path is the sequence of tasks that determines the minimum project duration. It includes activities with the longest duration and, therefore, the path where any delay will directly impact the project’s overall timeline.

- Linear Relationship Between Cost and Time: CPM models the network as a linear relationship between cost and time. This relationship helps in optimizing the project by finding the balance between completing the project quickly and staying within budget.

- Deterministic Durations: Unlike PERT, CPM is applicable only to activities with deterministic durations—those with fixed, known timeframes. This makes CPM particularly suited for projects where activities can be clearly defined and scheduled.

- Least-Cost Scheduling: CPM can be used to determine the most cost-effective way to schedule the project. By analyzing different scheduling scenarios, project managers can identify the approach that minimizes costs while meeting the project deadline.

- Focus on Earliest Completion Time: One of the primary outputs of CPM is the earliest possible completion time of the project. However, unlike PERT, CPM does not account for uncertainty in activity durations and does not estimate the probable completion time.

Advantages of CPM:

- Suitability for Well-Defined Projects: CPM is ideal for construction, manufacturing, and other projects where tasks and timelines are well-defined and predictable.

- Optimization of Time and Cost: By identifying the critical path, CPM enables project managers to focus on the most crucial tasks and optimize both time and cost for the entire project.

Clear Visualization of Project Timeline: The use of Arrow Diagramming and the focus on critical activities provide a clear visualization of the project timeline, making it easier to monitor progress and manage risks.

Program Evaluation and Review Technique (PERT)

The Program Evaluation and Review Technique (PERT) was developed in 1958 by the Special Project Office of the U.S. Navy Bureau of Ordnance in collaboration with the management consulting firm Booz-Allen and Hamilton. PERT was initially designed to manage the Polaris Missile program, a complex project requiring meticulous planning and control.

Key Features of PERT:

- Probabilistic Time Estimates: Unlike CPM, PERT uses probabilistic time estimates to account for uncertainty in task durations. PERT considers three different time estimates for each activity:

- Optimistic Time (O): The shortest possible time to complete the activity if everything goes perfectly.

- Most Likely Time (M): The most realistic estimate, assuming normal conditions.

- Pessimistic Time (P): The longest time the activity might take if faced with significant delays.

- Three Time Estimates: The inclusion of these three time estimates makes PERT a “three-time estimate” technique. This approach is advantageous over CPM, as it not only considers the uncertainty in activity durations but also provides information on the probable completion time of the project.

- Resource and Performance Specifications: PERT is also concerned with the resources required for each task and the technical performance specifications that must be met. This ensures that the project not only stays on schedule but also meets all quality and performance requirements.

- Critical Path Calculation: Although CPM and PERT were developed independently, the methods adopted for computing the critical path are quite similar. PERT calculates the expected value of activity duration as a weighted average of the three estimates, allowing project managers to identify the critical path in the same way as CPM.

Advantages of PERT:

- Flexibility in Uncertain Environments: PERT’s probabilistic approach makes it particularly useful for research and development projects or any other projects where task durations are uncertain.

- Interchangeability with CPM: In current practice, the terms PERT and CPM are sometimes used interchangeably due to their similar computational methods, even though they were developed for different types of projects.

Probability of Completing P(T) of a project by a specified duration Ts, or less is given by

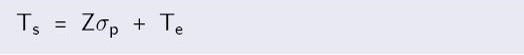

To find the project duration that corresponds to a specified % chance of completion, rearranging the variables in equation, we have,

Where,

Te is the project mean duration

σp is the project standard deviation

Other construction scheduling methods like Precedence Diagramming Method (PDM), Linear Scheduling, Stochastic Network – Graphical Evaluation and Review Technique (GERT), Repetitive Scheduling (RS) and Short-Interval Scheduling (SIS) were initially developed independently for industrial sectors and later applied in the construction industry. However, a thorough introspective assessment of these scheduling methods for construction projects is necessary.

Conclusion

The aforementioned construction scheduling methods are not an exhaustive list but the most commonly used scheduling methods. Some of the modern construction project management concepts such as Location Based Management Systems (LBMS), Design Structure Matrix (DSM), and Lean Construction and so on, can be used with these scheduling methods to gain many insights about the project and also to enhance the versatility of the construction scheduling methods.

About the Author

The author is a distinguished expert in Applied Artificial Intelligence for Civil Engineering, Automation in Construction, and Building Information Modeling. His extensive expertise spans Constructability Analysis, Construction Project Management, and Concrete Formwork Systems, alongside the integration of Internet of Things (IoT) technologies into civil engineering applications. Additionally, he is skilled in advanced fields such as Mixed Reality, Resilient Design and Construction, and Structural Optimization.