Over the past few years, India has seen a spurt in the vertical growth of buildings. They range from individual houses to very tall skyscrapers. Whenever news on earthquake is reported, we have only one question in our mind – Is building safe during an earthquake?

Engineers always tell us that earthquake don’t kill, but that will be done by poorly built constructions. Earthquake resistant buildings can be made, only by constructing our homes with ductile character. For a better understanding in earthquake resistant buildings, we must acquire knowledge about earthquakes and its occurrence. The points are given as below;

How an earthquake occurs?

The earth’s crust can be viewed as a thin shell, made of rocky material that overlies a molten core. This shell has a large number of cracks in it. Thus it effectively divides the crust into a series of large plates named as tectonic plates.

Under the influence of gravitational force, forces due to convection happening in the earth’s core and due to the forces induced due to earth’s rotation, these tectonic plates are constantly pushed against each other. This causes stress and strain energy started to develop within each tectonic plates and along the boundaries between these plates. Over a period of hundreds of years, these stresses accumulate to a point where they can exceed the strength of the rocky crust itself. This creates a differential movement of earth’s crust which in turn releases the strain energy stored over the years, in the form of kinetic energy. Thus seismic waves from earth’s crust propagate to surface soil causing ground shaking and other seismic effects.

When and where earthquakes occur?

We can’t predict when an earthquake will occur, accurately. It could happen anytime, anywhere. But collected historical data shows that most earthquakes occur at faults, where earth’s crust is weaker. As earth’s crust changes over years through geological and tectonic activities, the built up of stresses may also change the pattern. So faults may always change its zones over different geologic areas. Constant research and monitoring is needed on this phenomenon.

Can we measure the earthquake?

The earthquake is measured using the magnitude and intensity factors. Magnitude is the objective measure of earthquake size. It represents the amount of energy releases by an earthquake event. During an earthquake, seismic waves radiate outwards decreasing in its amplitude, just like ripples that form around the place where a stone falls in to the pond.

The earthquake turns to be more catastrophic at the source. In some locations, topography and soil conditions may increase the destructive potential of the earthquake which is measured as its intensity.

Most of the earthquakes are of small magnitude and intensity even though several thousand tremors occur worldwide in a year. But larger earthquakes releases high energy which was accumulated over hundreds of years. These earthquakes exhibit high magnitude and intensity.

Why do buildings collapse during an earthquake?

Most of the earthquake induced building changes occurs as a result of buildings responds to ground shaking. The foundation of a building shakes in accordance with the shaking of the ground. The portion of the structure above the foundation usually fails if it is of brittle nature. All structures have a mass and therefore inertia and certain level of flexibility. During shaking, the structure above the foundation will lag behind. In short base of the building moves laterally and vertically relative to the elevated flows and roof. This relative displacement results in producing forces which cause further deformation of the structure.

Can we really make earthquake resistant buildings?

While there is no denying on the power of earth’s fury, there is however a lot that can be done in terms of adhering to certain construction strategies to minimise the impact of destructive earthquakes.

Earthquake resistant buildings are constructed on the basic concept that soil must be stronger than the foundations; foundation must be stronger than the columns and beams. By constructing earthquake resistant buildings, we mean, we create building of more ductile nature. TMT construction steel bars play a very critical role in increasing the ductility of buildings. Until Lathur earthquake disaster happened steel bars were considered as those which compliment the disadvantage of concrete- ie tensile strength. Steel bars made during that period were having higher carbon content, so as to increase the strength. Much of the disaster’s destructive potential was exponentially multiplied due to the brittleness of steel bars.

Soon after the Lathur earthquake, we started researches on resisting severe earthquakes. Construction of modern seismic resistant buildings focus on the following 3 significant factors;

- Building must be made out of a proper earthquake resistant design.

- Make use of most modern earthquake resistant techniques in the constructions.

- Earthquake resistant ductile material must be used for construction.

Now-a-days, two major issues act as constraints to implement the above principles.

They are;

- Lack of team work among resource persons.

- Utilization of one factor but ignoring the importance of other two.

- Lack of teamwork among resource persons: Usually an architect makes a plan and then the engineer designs the building. This result in certain level of compromising situations on the engineers design side. It is better that an architect and engineer must act as a team from the planning stage of the building. They should also properly communicate their intention for making an earthquake resistant building to the contractor also.

- Over confidence by implementing one factor, but totally ignoring the other two factors meant as basic principles of earthquake resistant constructions.

All the three factors should be considered in making earth quake resistant buildings. If building materials are seismic resistant and if design is not, there is no benefit. Recently there is another trend reported by contractors that the customers buy certain building material, wrongly believing that they will deliver total earthquake resistance for their homes. Intense competitions among manufacturers compel some among them to make use of certain unethical marketing techniques for selling their building materials. Steel bars used for civil construction accounts for most of these fraudulent selling methods.

We could see a lot of customers buying TMT brands with EQR certification or logo stamped in the TMT. Even though the manufactures doesn’t claim EQR as a grade of TMT, they widely creates such an impression through catchy advertisements and promotions. A customer who strongly believes that the EQR steel used in the construction of his home, must realize that the fraudsters have taken him for a ride.

Bureau of India standards in its IS code 1786 clearly describes the various grades of TMT to be used in India. They are listed below;

- Fe415, Fe415D, Fe415S

- Fe500, Fe500D, Fe500S

- Fe550, Fe 550D

- Fe600

There is no EQR grade in the above standards. One must understand that EQR is just a marketing gimmick created by a few fraudulent steel manufacturers to sell off their products at higher rate. On observing the above codes, we could understand that the TMT grades must be marked with ‘Fe’ as prefix followed by a number. The number indicates the tensile strength of the steel, while ‘Fe’ stands for iron. A grade will be considered only if both components are there. Here you could smell another way of cheating in the market. There are a lot of steel suppliers who label the TMT their brand name followed by a number.

Customers perceive this number to be an indication of the strength of that TMT steel bar. At the same time, these suppliers escape from the hands of BIS as on questioned, they argue that they have just quoted a number. For eg. ‘ABC 500D’ TMT falsely creates an impression that ‘ABC’ brand is having minimum 500 n/mm2 yield strength and is also more ductile. But practically it will not be having even 415 N/mm2 strength. Similarly ‘XYZ EQR TMT’ doesn’t mean it could protect building from Earthquake.

1) What are the points, we must consider on seismic resistant design?

- Always consider the historical collected data of seismic activities in the zone.

- Do specific local investigations to develop the local design response spectrum. Sometime the local ground motion parameters and structure response may differ substantially from the value obtained with design response spectrum of the zone.

- Sandy or muddy soils must be checked for their liquefaction potential as much soil will behave like a liquid during an earthquake.

- Foundation of structure must be designed to be always in the elastic range. The path of compression, shear and tensile forces can be transferred from plastic zones of structural walls through the slab to extension walls and finally to the raft.

- One earth quake resistant building design, care must be taken to ensure that the stair case slabs are integrally connected to the frame of the building to prevent collapse. The only escape route in most of the buildings during an earthquake is the staircase. So it shouldn’t fail.

- A strong core shear wall usually designed in the elevator area must be considered on earth quake resistant building designs. These shear walls could provide necessary stiffness to the buildings during an earthquake, avoiding excessive sway.

- Earthquake resistant design of buildings must take care to avoid offset and asymmetrical bracings as these may result in weakening the seismic resistance and ductility of buildings.

- BIS provisions or seismic resistant design must be strictly followed. 57% of total area in India comes under seismic zones. IS 1893:2002 clearly describes India as a seismic risk area. It describes zone II, III, IV and V based on the risk of earthquake occurrence. Another BIS code IS 4326:1993 provide guideline in selection of material to be used in earthquake resistant constructions. The code emphasis the parameters as lightness, continuity of construction avoidance of suspended and projected members etc. But most importantly the focus is given on ductility of the structures, as per this code.

BIS code IS 13920:1993 is very important code to be followed in earthquake resistant building construction. This standard gives the code of practice to be followed in ductile detailing of reinforced concrete structures, which are subjected to seismic force. The code suggests that earthquake resistant buildings must be made with high strength defined steel bars of grade Fe 415 or less.

- Earthquake resistant design must consider the bracing of reinforced masonry wall with reinforced members. This will improve lateral load resizing capacity of building during an earthquake.

- Stiffening of structural masonry walls by reinforcement in longitudinal direction improves lateral strength and ductility of the buildings. This must be considered on designing.

Engineers must make use of the above BIS standards and provisions, while doing an earthquake resistant construction.

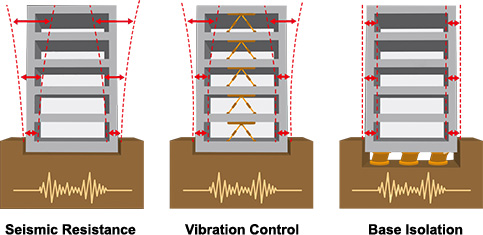

2)How we could make use of most modern seismic resistant construction techniques during building an earthquake resistant construction?

Normally we think that strengthening of building is essential for its earthquake resistance. But sometimes it may practically more beneficial if we soften the structures. A better way in avoiding catastrophic failure in local bearing structures, is by creating a disconnect between the foundation of building and the rest of the above ground structure. Base isolating techniques are widely used in Japan and USA for the same.

American technology: American technology makes use of isolating the structure from the foundation using an air compression fill in between.

Japanese technology: Japan as a country, is at the forefront of earthquake resistant technology. Strong building codes are implemented in Japan with specific rules for short, midrise and tall buildings. Medium and taller Japanese buildings rest on huge rubber, fluid filled shock absorbers, which could stick side to side dissipating lateral motion which in turn gets converted into heat energy. Relatively smaller buildings rest in Teflon coated pegs embedded in the foundation. The weight of the structure anchors the building on the pegs, but when the ground shifts the entire building slides over the smooth surfaces.

Beam – column joint area must be taken care in construction of earthquake resistant building, to avoid the diagonal cracking and crushing of concrete. Closely spaced closed loops of steel are required around column bars to hold together concrete in joint region and to resist the shear forces.

Anchoring of longitudinal beam bars into the column will ensure proper gripping of concrete in the exterior joints where beams terminates at columns.

How usages of earthquake resistant building material ensure safety of one building?

Continuous research on developing earthquake resistant building resulted in development of high strength steel bars with superior ductibility, made out using TMT technology. Various grades of TMT steel are available in the market such as Fe 415, Fe500, and Fe550 etc. They have their own characteristics that make them suitable for specific applications. All these grades are manufactured using same TMT process but with little tweaking. In the TMT process, steel bars are quenched rapidly for a short interval of time under controlled conditions. This results in development of a tempered martensite outer core and a ductile ferrite-pearlite inner core. If the steel is quenched more, the outer martensite layer will become thicker at the expense of the soft inner core. As the outer core gives tensile strength and inner core endows the bar with ductility (ability to deform without breaking.), a slight reduction in ductility has grave consequences for the safety of the buildings, especially during earthquakes. We must realize that Fe415 is the default option and commonly used grade while other grades are for special use.

When a customer steps into shop selling steel rebars, he will find a variety of offerings, including standards Fe415 and other specific grades. We must understand that all these grades deliver strength and ductility for the buildings. All grades apart from most commonly used Fe415 are used for special applications where it is essential. In these cases, BIS has taken steps to nullify the decrease of ductile character. Thus ‘D’ (Ductile) and ‘S’ (seismic) versions originated. In short the advantages of not using Fe415 is practically reduced by usage of ductile and seismic versions (Fe 415 and Fe500 s)

There are a lot of fake grades like EQR (Earthquake resistant) steel which we described in the initial part of this paper. Designers / engineers should accept TMT bars only after proper testing and verification of the same irrespective of the name of the brand / manufacturer. Asking for a test certificate and a computerized plotted stress strain graph will help us to identify the ductility part of the steel purchased and its tensile strength. Always assure that the grade Fe415 is the TMT grade of steel you purchase for earthquake resistant buildings (As suggested in IS 13920:1993)

Rib formation in the TMT steel bars is another factor that needs to be taken into consideration when buying earthquake resistant TMT steel bars. It is the properly ground rib formation that bonds TMT steel bars with the concrete.

Stirrups made out of TMT steel bars used in RC beams prevent the buckling of compressed longitudinal bars. Stirrups also resist vertical shear cracks. Both the end of vertical stirrups must be bent into a 1350 hook. The ends need to be sufficiently beyond the hook to avoid opening up of stirrup during a seismic activity.

Do steel with higher UTS results in brittle failure during an earthquake?

BIS code IS1786 amendment describes the values of mechanical properties to be shown by different grade of TMT. While most commonly used Fe415 grade must give minimum 415N/mm2 yield strength and not less than 485N/mm2 ultimate tensile strength, the code says that Fe 415S (Seismic variant) must give minimum 415N/mm2 yield strength and maximum ultimate tensile strength value should be 540N/mm2.

Yield strength of a material is the amount of loading where the steel starts to deform plastically. Ultimate Tensile Strength of a material is the amount of loading when the steel break up in to two entirely separate pieces. Once the steel crosses its UTS, the amount of load it can transmit drops immediately to zero.

Earthquake resistant buildings are always constructed to have ductile failure. When load exceeds UTS, the entire building may collapse. A high number of causalities can occur when a structure fails with no warning, that it is overloaded. The ability to see or hear structural components starting to yield can give occupants a warning sign. In the mean time, they could save their lives. The point is that higher level of UTS results in sudden failure of structure without much warning.

Another point is that if one component of the structure fails it could transmit the shock and impact loads to other components of the structure. So a load exceeding the UTS, these single components failures can cascade into a serious damage. If the material could yield and deform significantly before failing it can absorb the impact energy. Thus it could prevent it from transmitting elsewhere. In the case of automobiles there will be a crumple zone for safety of passengers. The crumple zones in automobiles are located in front part of the vehicle in order to absorb the impact of head on collision.

Similarly yielding for a while than having higher UTS is practically considered better in earthquake resistant buildings.

Enhancing strength without losing ductility.

Micro alloying is the best method to achieve desired strength for specific TMT grades without losing its ductility character. Restricting the impurities like sulphur and phosphorous and by controlling the carbon content compliment to this. But the technology is yet to come up in India. As of now, all the steel producers make use of TMT process for manufacturing high strength steel bars with superior ductility. Once micro alloying process is used, conditions may change. Till then FE415 grade is the best option of TMT which offer earthquake resistance.

Also authorities like BIS must periodically check whether compliance to the seismic resistant codes is done or not. Providing safe structure certificates to building under construction is another method to ensure earthquake resistant building construction.

Nothing can fully guarantee your home complete resistance to earthquake, but implementing the above points could help in achieving the best possible option to protect our buildings from the disaster of earthquake.

References:

- Broderick-Book on Earthquake ,observations and coorelative response Analysis-Imperial College, London

- Nateghi-Work on Seismic Upgrade design of Lowrise and Skyscrappers in Japan

- “A clear and present danger in use of High Grade TMT in Seismic Zones”-Emilio M.Morales(Fellow in Civil Engineering, Carnegie Mellon University)

- “Critical Properties of Seismic Resistant Rebars” – Dr.A.M.Elmaghrabi P.hD (Inorganic and analytical Chemistry).

- Priestley- Lecture on Seismic Design and prevention measures ,Australia

- “Indian Standard Specification for High Strength deformed bars and wires for concrete reinforcement (third revision), IS 1786:1985; Bureau of Indian Standards, New Delhi

Author’s Bio:

Mr.Jismon Issac has 18 years of experience in the manufacturing & Quality testing of Construction Steel bars especially High grade TMT steel bars.He is a regular writer on technical matters related to Indian Construction sector.