Shoring is lateral support, usually temporary, that is used during the repair or original construction of buildings and in excavations. It can be utilized when walls bulge out when walls crack due to unequal settlement of foundation and repairs must be carried out to the cracked wall, when an adjacent structure needs pulling down when openings must be newly enlarged or made into a wall. Shoring in Construction is essentially required to support a deep excavation to prevent the retained soil from overturns and eventually cause a project mishap. Its support requirement depends on the types of soil and when an excavation depth is at least 1.20-meter difference in levels from ground level.

Requirement of Shoring

- If the wall shows signs of bulging out due to bad workmanship.

- To repair a crack on the wall due to unequal settlement of the foundation.

- When an adjacent structure is to be dismantled.

- If openings are to be made or enlarged in the wall.

- To give support to walls that are dangerous or are likely to become unstable because of subsidence, bulging, or leaning.

- For avoiding failure of sound walls caused by the removal of underlying support

- During demolition works to give support to an adjacent building or structure.

Different types of shoring

Each shoring system has its own function to perform and is based upon the principles of a perfectly symmetrical situation. There are three types of shoring as discussed below.

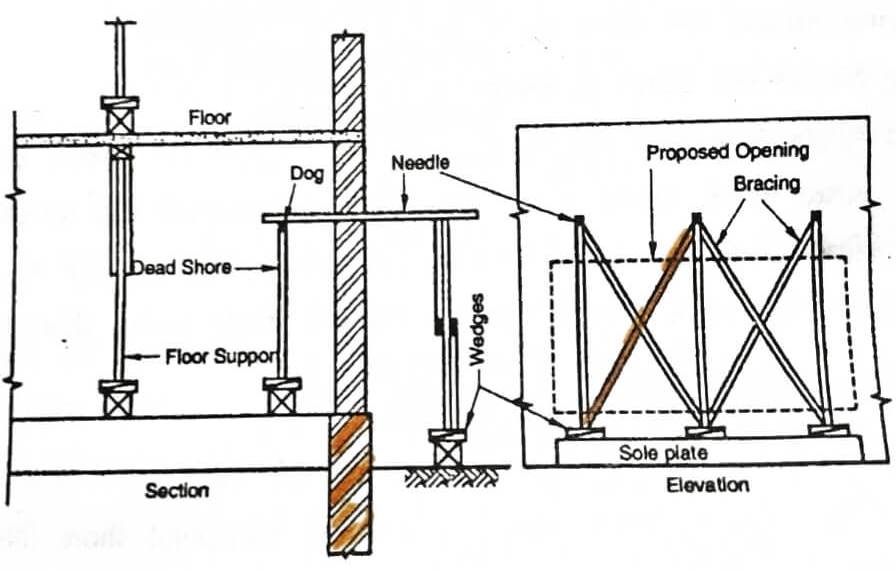

Dead Shoring

Dead shoring is used to temporarily support the walls, roofs, floors, etc., by providing horizontal members known as needles. This type of shoring is used to support dead loads that act vertically downwards. It consists of a vertical prop or shore leg with a head plate, sole plate, and some means of adjustment for tightening and easing the shore. The usual arrangement is to use two sore legs connected over their heads by a horizontal beam or needle. The loads are transferred by the needle to the shore legs and hence down to a solid bearing surface.

It may be necessary to remove pavings and cut holes in suspended timber floors to reach a suitable bearing surface; if a basement is encountered, a third horizontal member called a transom would be necessary because it is impracticable to manipulate a shore leg through two stories. The dead shores stand away from the wall on either side to allow for working space when the needle and the props are in position. The props are tightened up by folding wedges provided at their bases while the junction between the prop and the needle is secured with the help of dogs. Before the dismantling work is started, all the doors, windows or other openings are well strutted. To relieve the wall load of floors and roofs above, they are independently supported.

Dead shoring is used to build the lower part of a defective load-bearing wall, deepen the existing foundations, which have either become unsafe or require strengthening and large openings in the existing walls for doors and windows. This type of shoring system is kept away from the wall for easy repair work. Dead shores are supported and anchored on plates and folding wedges.

Factors to consider for dead shoring

- The needles are spaced at 1 to 2 meters

- Needles should be suitably braced

- Folding wedges should be inserted between the two

- The floors should be suitably supported from inside

- Fix ceiling struts between the suitable head and sole plates to relieve the wall of floor and roof loads

- Strut all window openings within the vicinity of the shores

- Cut holes through ceilings and floors for the shore legs

- Leave the shoring in position for at least seven days before starting new work

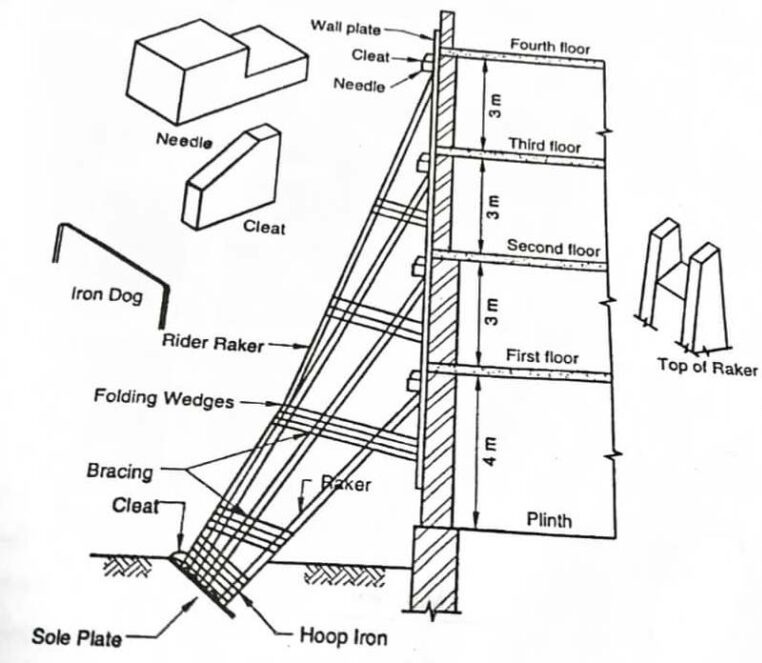

Rake shoring

Rake shoring is used to support any walls that aren’t structurally sound within a building. Using cleats, needles, sole plates, inclined members, bracing and wall plates, they help to keep walls intact to minimize any damage to the existing building or structure. It is used to transfer the floor and wall loads to the ground utilizing sloping struts or rakers. The rakers must be positioned correctly so that they are capable of receiving maximum wall and floor loads.

A rakie shoring consists of the following components, rakers, wall plate, needles, cleats, bracing and soleplate. Rakers against the needles in such a way that the centerline of the raker and the wall meet at the floor level. Thus, there will be one raker corresponding to each floor. These rakers are inter-connected by struts, to prevent their buckling. An inclined soleplate is embedded into the ground on which the feet of rakers are connected. The feet of rakers are further stiffened near the soleplate using hoop iron. The wall plate distributes the pressure to the wall uniformly.

Factors to consider for rake shoring

- Rakers should be inclined to the ground by 45° to 75°,

- Length of raker can be reduced by introducing rider raker.

- Rakers should be properly braced at intervals.

- The centre line of a raker and the wall are maintained at the same level of floor.

- The sole plate should be properly embedded into the ground, at an inclination and should be of proper section.

- Wedges should not be used on sole plates

Flying Shoring

Flying shoring is a support system that provides horizontal support to two parallel party walls when removal or collapse of the intermediate building takes place. These are most often used for supporting temporarily the parallel walls of two adjacent buildings where an intermediate building has to be demolished or rebuilt. Essentially the scaffold would be built through the middle and ‘wedge’ between the adjacent buildings. The flying shore consists of wall plates, struts, straining pieces, horizontal shore, needles, cleats and wedges, as shown in the above image. Like inclined shores, in this system also, the wall plates are secured against the walls using needles and cleats.

In this type of shoring also the wall plates are placed against the wall and secured to it. A horizontal strut is placed between the wall plates and is supported by a system of needles and cleats. The inclined struts are supported by the needle at their top and by straining pieces at their feet.

Points to consider for flying shoring

- The center lines of flying shore and struts and those of the walls should meet at floor levels of the two buildings.

- The struts should preferably be inclined at 45°.

- Single shores should be used only up to 9 m distance between walls.

- Should be spaced at 3 to 4.5 m centers, along the two walls; and horizontal braces

Conclusion

Different types of shoring, their requirements and their components have been discussed above. Your selection will be dependent on the need and support and stability of the unsafe structures. Shoring can provide support to the structures when certain alterations) are necessary to be done in the structure when it is undergoing repair.