Heavy equipment or heavy machinery refers to heavy-duty vehicles, specially designed for executing construction tasks, most frequently ones involving earthwork operations or other large construction tasks. There are different types of heavy equipment each performing different and required for different construction activities.

Given below is a list of the most used heavy equipment used in construction

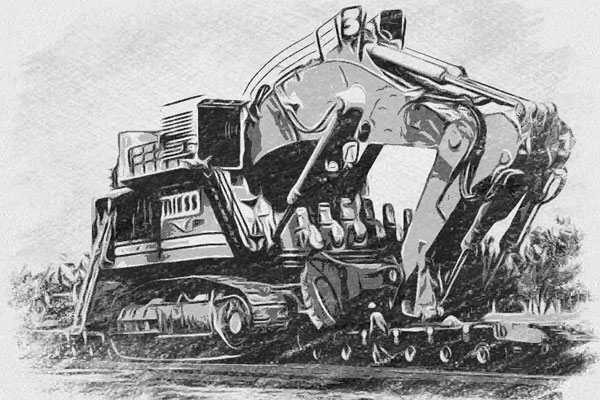

Excavators

The modern range of Excavators comes with factory fitted Advanced Telematics called Live-Link so that you stay in command, always. The technology lets you have real-time access to the operational activity and work report of your fleet of machines. It is the most in-demand heavy equipment because of its functioning terminology consisting of a boom, dipper (or stick), bucket and cab on a rotating platform known as the “house”. The three main sections of an excavator are the undercarriage, the house and the arm (also boom is used). The undercarriage includes tracks, track frames, and final drives. The house includes the operator cab, counterweight, engine, fuel and hydraulic oil tanks. The house attaches to the undercarriage by way of a center pin. High-pressure oil is supplied to the tracks’ hydraulic motors through a hydraulic swivel at the axis of the pin, allowing the machine to slew 360° unhindered and thus provides the left-and-right movement.

Backhoe

Modern backhoes are powered by a better engine and deliver powerful performance and fast response time coupled with higher productivity and fuel savings of up to 13%. They are re-engineered from the ground up to deliver industry-leading backhoe breakout force, greater loader lift capacity/reach, and cab visibility. The new series Backhoe have robust robotically welded two-piece structural frame design results in great stability, performance and serviceability. Large box-section structures in high-stress areas such as the boom nose, foot and cylinder enhance the machine’s durability. The new heavy-duty front axle with double effect steering cylinder ensures all wheels remain in contact with the ground even on the roughest terrain, ensuring exceptional stability and reliability. The hydraulically shifted clutches allow the operator to change direction and travel speed on the go, while the control valves deliver smooth speed and direction shifts, resulting in smooth and accurate operation. The new tilting engine hood provides excellent access for maintenance.

Next Generation Cat® Excavators

JCB 3CX backhoe loader

Dragline excavator

A dragline excavator is a piece of heavy equipment applicable in civil engineering, surface mining and excavating. A large excavator uses a dragline to pull a bucket by a wire cable. The operator lowers the bucket down to the material that is supposed to be excavated. The operator then draws the cable so that the bucket gets dragged along the ground surface and digs into the material. After a while, the operator releases the drag cable and lifts the bucket to the place where the material it scooped up will be dumped. New series draglines have a bucket capacity ranging from 76m³ to 116m³ and 5,800t to 7,500t of working weight. The new series has a suspended load capacity of up to 383,286kg.

Bulldozers

The bulldozer is iconic equipment in the class of machines known as heavy equipment. Also known as dozers, track-type tractors or crawler tractors, they are synonymous with power and reliability. They are equipped with a hydraulically operated horizontal blade for moving large quantities of earth, rock and other material. The dozer is mounted on tracks and uses its broad blade for land clearing, grading, excavating, placing and transporting materials. Dozers are used in construction projects, mines, agriculture and forestry. Bulldozer is equipped with a substantial metal plate (known as a blade) used to push large quantities of soil, sand, rubble, or other such material during construction or conversion work and typically equipped at the rear with a claw-like device (known as a ripper) to loosen densely compacted materials. It is usually a crawler (continuous tracked) tractor. Bulldozers can be found on a wide range of sites, mines and quarries, military bases, heavy industry factories, engineering projects and farms.

Dragline excavator on work

Intelligent bulldozers provide productivity boost

Motor graders

New series motor graders are well-equipped models ideally suited for small-to-mid-size grading operations for municipalities, road maintenance and general construction. Their new engine solution delivers fuel-saving performance with minimal cost or maintenance from the operator and with the product assurance of ProCare, ownership and upkeep has never been easier. Models come standard with the productivity-boosting features operators want and are available as standard drive or AWD, and as machine control-ready for integrating into precision fleets. Motor graders or alternatively called road graders or graders are absolutely necessary equipment at any construction site. They are usually self-propelled machines with an adjustable blade. Typical motor grader models have three axles with the engine and cab situated above the rear axles at one end of the vehicle and a third axle at the front end of the vehicle with the blade in between. Motor graders are generally identified by their long adjustable blade and considered to be easy-to-use equipment for mining underneath the ground.

Wheel tractor-scraper

A wheel tractor-scraper is a piece of heavy equipment used for earthmoving. The rear part of the scraper has a vertically moveable hopper with a sharp horizontal front edge which can be raised or lowered. The new generation wheel tractor-scrapers have the power, traction, and speed for reliable output in a variety of earthmoving applications. Scraper options include single-engine and tandem-engine open bowls, tandem engine push-pulls and elevator arrangements. The features, including high-pressure steering, engine over-speed protection, tire spin reduction, differential lock engagement protection, machine/ground-speed control, and a payload-estimator system are also built in modern wheel tractor scrapers. The new models incorporate a number of additional enhancements such as advanced Cushion Hitch hydraulic-system refinement, Auto-Stall assists, cab interiors feature a redesigned dash as well as visibility and operator comfort enhancements; maintenance etc.

CASE Motor Graders on work

Wheel tractor-scraper Caterpillar

Trenchers

Trenchers are designed for cutting narrow, straight trenches. Modern-day trenchers can produce trenches with perfect profiles in widths from 20 to 60 centimeters to a maximum depth of 2 meters New age trenchers come with a wheel fitted with rim buckets, or with a boom or ladder on which an endless chain of buckets or scrapers revolves. The machine is self-propelled on rubber tires or crawlers (continuous metal treads driven by wheels). As the machine moves forward, it rotates the ladder or wheel so that the buckets dig at their forward edge. They dump onto a conveyor belt or a chute that piles the cuttings on either side. Trenching machines can be equipped to cut hard ground and even soft rock, but they encounter difficulty with boulders. Trenchers are very similar to excavators as both types of machinery are able to break and remove soil and rock from the ground. Unlike excavators, trenchers have the ability to remove soil in a continuous movement. These machines are often used to dig trenches for pipes and cables.

Loaders

Loaders are best suited for earthmoving, road construction, agricultural purposes, and also in large and small scale constructions which include marine structures. A loader is a heavy equipment machine used in construction to move aside or load materials such as asphalt, demolition debris, dirt, snow, feed, gravel, logs, raw minerals, recycled material, rock, sand, woodchips, etc. into or onto another type of machinery (such as a dump truck, conveyor belt, feed-hopper, or railroad car). There are many types of loader, which, depending on design and application, are called by various names, including bucket loader, front loader, front-end loader, payloader, scoop, shovel, skip loader, wheel loader, or skid-steer.

Trenchers on work

Komatsu Wheel loader on work

Tower cranes

Tower Cranes are used for civil construction and erection jobs. Fixed Tower Crane is used for bigger construction projects. New age tower cranes come up with a new system that has additional features of safe load indicator (SLI) inbuilt, those the customer need not by a separate SLI and separate Anti-Collision device, both are inbuilt in one system itself. Furthermore, there is a development of a fast-erecting system and a top-slewing system. The benefits of fast-erecting cranes include rapid erection and versatility in use. This means that these cranes can be used to build detached and multi-occupancy houses as well as small infrastructure projects. Top-slewing cranes can adjust to any specific customized requirement.

Paver

New age pavers are designed to execute operations of Road repair and reinstatement, Bicycle path paving, car parks, decks, and Landscaping. The newer models give paving results of superior quality by having a heavier screed with tamper bars. They are designed to meet and surpass your needs in terms of precision, efficiency and ergonomics. The end result is an impressively high paving performance, including the achievement of excellent compaction values.

Tower Crane on work

GOMACO, Concrete Slipform Paving Equipment on work

Compactors

Modern-day compactors combine climbing power, high centrifugal forces and 360-degree visibility to provide you with superior productivity and power. The whole compaction line offers easy operation. The compactor is equipped with unique features and robust structures that enable you to build strong roads. Whether it’s a single drum soil compactor or a vibratory tandem road roller, every compactor offers an efficiency which is more than what you expect. In addition, the machine is equipped with LiveLink and Compaction Coach – a Compaction Monitoring System that has been introduced to strengthen the roadways industry. It optimizes the number of passes and enables you to monitor the operator’s performance with real-time compaction alerts.

Telehandlers

New age telehandler offers excellent lift capacity, making it an ideal machine for loading/unloading and moving/placing materials They come with the military-grade chassis design, quick attachment system and auxiliary hydraulics. Telehandler capability ranges from models with a lifting capacity of 6,000 pounds and a lift height of 20 feet, to models that might lift in excess of 20,000 pounds to 100 feet.

Compactors Tandem rollers Pneumatic tire rollers

Telescopic Forklifts (Telehandlers) on work

Dump Trucks

New generation dump trucks can transport heavy loads quickly, easily and cost-effectively. Available in rigid or articulated versions with state-of-the-art designs, they are built around a powerful engine and are exceptionally strong machines. They guarantee complete driving safety, even at high speeds. From the transmission system and chassis to the axles and suspension, all the components are designed to handle grueling daily stresses for maximum reliability. Dump Trucks are typically used for hauling material over the road or around a job-site. They typically feature a cab similar to that of a Truck Tractor but offer a hydraulic dump bed. Dump Trucks come in varying axle configurations, which typically limit the weight you are capable of hauling.

Pile driving equipment

Pile driving equipment is designed to align and hold piles in the correct position and to drive the piles into the ground. Equipment of this type can also be used for extracting piles from the ground. Pile-driving equipment includes a weight-lifting device and a driver, which is usually mounted on a pile driver or on a truck, tractor, railroad platform, excavator, or crane hoist. Pile-driving equipment is classified according to the principle used in operating the driver as striking, vibratory, or jacking. It is designed to align and hold piles in the correct position and to drive the piles into the ground. Equipment of this type can also be used for extracting piles from the ground. Pile-driving equipment includes a weight-lifting device and a driver, which is usually mounted on a pile driver or on a truck, tractor, railroad platform, excavator, or crane hoist. Pile-driving equipment is classified according to the principle used in operating the driver as striking, vibratory, or jacking.

Mack Defense M917A3 Heavy Dump Trucks

Piling methods for deep foundation

Conclusion

Each type of heavy equipment serves an individualistic purpose, so while choosing, be sure the equipment serves your project needs. It’s important to choose the right piece of equipment for the job to maximize productivity and cost-effectiveness.

Image Source: cat.com, commons.wikimedia.org, heavydutydirect.ca, worldhighways.com, casece.com, napipelines.com, komatsu.eu, jkcrane.com, gomaco.com, wirtgen-group.com, abcinfra.com, volvogroup.com, liebherr.com

Comments are closed.