Different types of diaphragm wall construction machines are used for excavation and construction of diaphragm walls, which are reinforced concrete walls used in deep foundation projects. The diaphragm wall construction machine are equipped with a vertical digging tool, such as a grab or clamshell bucket that excavates a trench, installs reinforcement, and pours concrete in a controlled manner, ensuring the stability and strength of diaphragm walls. These are widely used in various construction projects, including buildings, bridges, and underground structures, these machines contribute to the overall efficiency and quality of the construction process.

How do the machines work?

1. Excavation:

– The diaphragm wall machine digs a narrow trench vertically into the ground.

– The depth and width of the trench depend on the project requirements and soil conditions.

2. Reinforcement Installation:

– Steel reinforcement cages, typically in the form of vertical bars, are lowered into the trench. These reinforcements provide strength to the diaphragm wall.

3. Slurry Trenching:

– During excavation, a slurry (usually a mixture of bentonite and water) is continuously circulated in the trench. This slurry helps to stabilize the surrounding soil and prevents collapse of the trench walls.

4. Concrete Placement:

– Once the required depth is reached and the reinforcement is in place, the trench is filled with high-quality concrete from the bottom to the top. This process displaces the slurry.

5. Curing and Hardening:

– The concrete is left to cure and harden, forming a solid diaphragm wall.

Advantages of diaphragm wall construction machines

- Used to remove soil and create a trench for the diaphragm wall.

- Facilitate the circulation of a stabilising slurry in the excavation area.

- Can install precast concrete or reinforced concrete panels into the excavated trench.

- Used to create cut-off walls for water control or containment purposes.

- Designed to incorporate reinforcement bars into the concrete panels.

- Offer precise control over wall thickness and alignment.

- Can expedite deep and wide trench excavation, reducing construction time.

- Suitable for various soil conditions.

- Minimises disruption to the surrounding environment.

- Streamlined construction processes reduce congestion on the site.

- Capable of significant depth excavation.

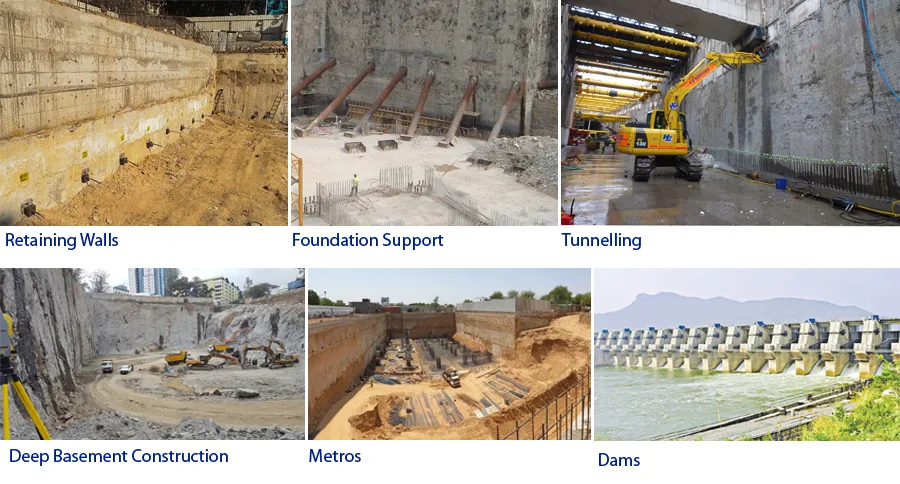

Uses of diaphragm wall construction machines

Different types of diaphragm wall construction machines

Grab Diaphragm Wall Machines:

Grab diaphragm wall machines are renowned for their robust construction and versatile soil excavation capabilities. Equipped with a reliable grab mechanism, these machines securely grasp and remove soil, creating precise trenches for diaphragm walls. Their adaptability allows them to excel in various soil conditions, maintaining stability across different terrains. The efficiency of the grab operation ensures effective excavation while upholding stability, making them a preferred choice for projects with diverse geological challenges. Whether it’s a foundation for a high-rise building or a waterfront structure, grab diaphragm wall machines excel in creating precise trenches across different terrains.

Hydraulic Clamshell Diaphragm Wall Machines:

Hydraulic clamshell diaphragm wall machines stand out for their precision in soil excavation and panel installation. Employing a hydraulic clamshell bucket, these machines provide accurate control over the excavation process, making them ideal for projects that demand high levels of accuracy. The hydraulic system enables efficient handling of challenging terrains, ensuring a steady and controlled operation throughout the diaphragm wall construction, contributing to the overall quality of the final structure.These machines are used for projects that demand accuracy, such as constructing underground structures or building foundations in densely populated areas.

Cutter Diaphragm Wall Machines:

Cutter diaphragm wall machines are recognized for their high precision and effectiveness in challenging conditions such as hard soils and rock. Utilizing cutting wheels, these machines excavate and create diaphragm walls with exceptional accuracy. The cutting mechanism ensures a clean and precise trench profile, contributing significantly to the overall quality and stability of the diaphragm wall. Their cutting wheel mechanism ensures clean and precise excavation, making them indispensable in applications like tunnel construction, underground parking structures, and projects requiring diaphragm walls in rocky terrains

Auger Diaphragm Wall Machines:

Auger diaphragm wall machines are well-suited for projects involving loose soils, showcasing adaptability to varying ground conditions. Relying on auger systems for soil removal and panel installation, these machines efficiently remove soil while facilitating the installation of diaphragm wall panels. Their adaptability makes them suitable for applications such as constructing retaining walls, creating foundations for industrial facilities, or establishing diaphragm walls in areas with fluctuating soil compositions. The auger system efficiently handles soil removal and panel installation, providing stability in a range of soil types.

Hydraulic Jetting Diaphragm Wall Machines:

Hydraulic jetting diaphragm wall machines use high-pressure water jets for environmentally friendly soil excavation and diaphragm wall construction. Particularly effective in cohesive soils, this method efficiently removes soil particles, creating a stable trench while minimizing environmental impact. The combination of hydraulic jetting technology and eco-friendly practices makes these machines a sustainable choice for diaphragm wall construction, aligning with modern environmental standards. These machines are used for waterfront structures, bridges, and other projects near water bodies.

Vibratory Diaphragm Wall Machines:

Vibratory diaphragm wall machines apply vibratory forces to aid in soil excavation and panel installation. This type of machine is especially effective in cohesive soils, where vibratory action reduces friction during the insertion of diaphragm wall panels. The vibratory mechanism enhances the efficiency of the construction process while ensuring the integrity of the diaphragm wall structure. The machine applications include the construction of deep basements, subway structures, and underground tunnels.

How to select the right machine for diaphragm wall construction?

- Selecting the right diaphragm wall machine involves a thorough assessment of project-specific requirements.

- Determine the required dimensions of the diaphragm wall, including depth, width, and thickness.

- Identify any specific project requirements, such as reinforced sections or load-bearing considerations.

- Conduct a detailed soil analysis to understand the soil composition and hardness at the construction site.

- Choose a diaphragm wall machine that is suitable for the encountered soil conditions.

- Consider the advantages and disadvantages of each type based on the project’s needs and constraints.

- Assess the machine’s reach and depth capacity to ensure it can meet the project’s excavation requirements.

- Choose a machine with sufficient reach to cover the entire wall length without the need for frequent repositioning.

- Consider the available space at the construction site.

- Evaluate the lifting capacity of the diaphragm wall machine to handle the required loads during excavation and construction.

- Ensure the machine can handle any additional equipment or accessories needed for specific project requirements.

- Consider features that enhance safety, productivity, and ease of operation.

- Assess the overall cost of the diaphragm wall machine, including purchase, maintenance, and operational expenses.

- Seek input from geotechnical engineers and equipment specialists to ensure alignment with project requirements.

By carefully considering these factors, you can choose a diaphragm wall machine that aligns with the specific needs of your construction projects.

Conclusion

The advent of wall construction machines marks a significant leap in the efficiency and speed of building processes. These innovative machines not only enhance productivity but also contribute to cost-effectiveness and improved safety on construction sites. As technology continues to advance, the integration of these machines is poised to reshape how diaphragm walls can be erected swiftly and with precision.

Image Source: casagrandegroup.com, sany.in, apollotechno.com,