Pre-Engineered Building design assembly involves the steel building systems which are predesigned and prefabricated. The basis of the PEB concept lies in providing the section at a location only according to the requirement at that spot

In pre-engineered building assembly components are done at the factory and the building components are brought to the site in knock down condition. An efficiently designed pre-engineered building can be lighter than the conventional steel buildings by up to 30%. Lighter weight equates to less steel and potential price savings in structural framework.

Design Assembly of Pre-Engineered Building system

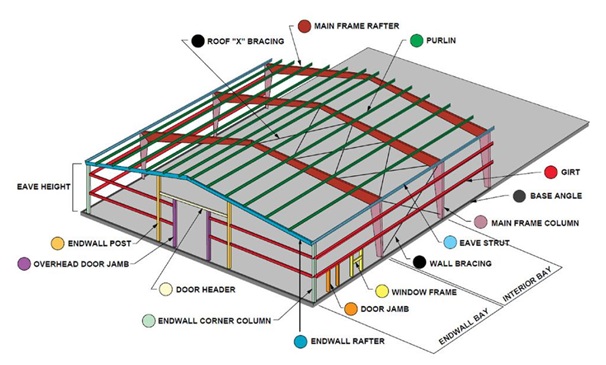

The designed assembly of pre-engineered building systems comprises various components, namely, Primary components, Secondary components, Sheeting (or) cladding, and Other Accessories.

PRIMARY COMPONENTS OF THE PRE- ENGINEERED BUILDING SYSTEM

Main framing

The main framing basically includes the rigid steel frames of the building. The PEB rigid frame comprises tapered columns and tapered rafters (the fabricated tapered sections are referred to as built-up members). The tapered sections are fabricated using the state of art technology wherein the flanges are welded to the web. Splice plates are welded to the ends of the tapered sections. The frame is erected by bolting the splice plates of connecting sections together. All rigid frames shall be welded built-up “I” sections or hot-rolled sections. The columns and the rafters may be either uniform depth or tapered. Flanges shall be connected to webs utilizing a continuous fillet weld on one side. All end wall roof beams and end wall columns shall be cold-formed “C” sections, mill-rolled sections, or built-up “I” sections depending on design requirements. Plates, Stiffeners, etc. All base plates splice plates, cap plates, and stiffeners shall be factory welded into place on the structural members. Built-up I section to build primary structural framing members (Columns and Rafters).

Columns

The main purpose of the columns is to transfer the vertical loads to the foundations. However, apart from the horizontal actions (wind action) is also transferred through the columns. Basically in pre-engineered buildings columns are made up of I sections which are more economical than others. The width and breadth will go on increasing from the bottom to the top of the column. I section consists of flanges and a web which are made from plates by welding.

Rafter

A rafter is one of a series of sloped structural members (beams) that extend from the ridge or up-to-the wall-plate, downslope perimeter or eave, and that are designed to support the roof deck and its associated loads.

SECONDARY COMPONENTS OF THE PRE- ENGINEERED BUILDING SYSTEM

Purlins, Grits, and Eave struts are secondary structural members used as support to walls and roof panels. Purlins are used on the roof, Grits are used on the walls and Eave struts are used at the intersection of the sidewall and the roof. They are supplied with a minimum yield strength of 34.5KN/m. Secondary members act as struts that help in resisting part of the longitudinal loads that are applied on the building such as wind and earthquake loads and provide lateral bracing to the compression flanges of the mainframe members for increasing frame capacity. Purlins, Grit-sand Eave struts are available in high-grade steel conforming to ASTM 607 Grade 50 or equivalent, available in 1.5 mm, 1.75 mm. 2.0 mm, 2.25 mm, 2.5 mm, and 3.0 mm in thickness. They come with a pre-galvanized finish, or factory painted with a minimum of 35 microns (DFT) of corrosion protection primer. Purlins and girts shall be cold-formed “Z” sections with stiffened flanges. Flange stiffeners shall be sized to comply with the requirements of the latest edition of AISI.

SHEETING OR CLADDING OF THE PRE- ENGINEERED BUILDING SYSTEM

The sheets used in the construction of pre-engineered buildings are composed of the following: Base metal of either Galvalume coated steel conforming to ASTM A 792 M grade 345B or aluminum conforming to ASTM B 209M. Galvalume coating is 55% Aluminum and about45% Zinc by weight. An exterior surface coating on painted sheets of 25 microns of epoxy-primer with a highly durable polyester finish. An interior surface coating on painted sheets of 12 microns of epoxy primer and modified polyester or foam. The sheeting material is cold-rolled steel, high tensile 550 MPA yield stress, with hot dip metallic coating of Galvalume sheet.

OTHER ACCESSORIES OF THE PRE- ENGINEERED BUILDING SYSTEM

Weather covering for roof and walls

To provide weather covering for roof and walls from the external condition, the steel structure needs to be covered fully/partially as per functional requirements. For all purposes, this covering provides access to all architectural and functional requirements as well. Normally, metal profiled steel sheets are used for covering purposes. Nowadays different color/color combinations are used to make building more aesthetic & elegant. There are various other elements of sheeting such as flashings, trims, ridge cover, peak panel, rack trim, drip trim, etc. which is made of the same material as of sheeting and equally important for weather tight functioning of the building. A proper rainwater gutter for the collection of rainwater and a pipe for the discharge of water from the gutter to the ground is also a key element to the building for the overall performance of the building. All sheetings are joined together with the help of self-drilling/self-tapping screw and necessary sealing material such as butyl tape, sealant, foam filler, etc. are used to make buildings more efficient.

Mezzanine system

Now a day’s construction of a mezzanine system is very common being used in steel buildings for various purposes. In most of the factory or warehouse building shop floor offices, production offices, stores, maintenance office, washrooms, canteen, etc. are made above the shop floor area wherever surplus head rooms are available. This also helps in saving the floor area as well creates ease of serving being close. This also reduces the cost of construction A typical mezzanine system is basically a joist beam construction taking support from the building columns as per availability and top of beams and joist deck slab is poured over GI decking of profiles metal sheet. A light reinforcement over decking and light concrete is used to make a permanent floor.

Anchoring

To install the steel building on the RCC pedestal/foundation, it is necessary to have an anchoring system suitably designed to take up various loads and forces of the building and to transfer the same to the ground through anchor bolts arrangement. The size of anchor bolts and its quantities are designed as per reactions calculated as per building design.

Building accessories

Various other building elements may not be important structurally but very important functionally and it adds the performance of the building. Skylight, wall light, Doors, windows, louvers, ventilators, turbo-vent, insulations, roof curb etc. are equally important to the smooth functioning of the building.

Crane system

All pre-engineered steel buildings can be designed for crane operation provision as per operational needs. There are various type of crane being used in industry for various purposes- EOT overhead crane with pendant or cabin operated, Overhung/under-slung crane system, Monorail crane or hoist system, Wall-mounted crane and Jib crane.

Paints and finishes

Pre-painted steel is produced on modern, high-speed coil painting lines where surface preparation before painting, paint application & paint curing is done on a highly automated line under optimum condition.

Conclusion

To accurately design a pre-engineered building, engineers should consider the clear span between bearing points, bay spacing, roof slope, live loads, dead loads, collateral loads, wind uplift, deflection criteria, internal crane system, and maximum practical size and weight of fabricated members All components of the design assembly PEB system are specially designed to act together as a system for highest efficiency. PEB designs are revised regularly to the actual field conditions and by various country codes, which resulted in improved standardized designs leading to the high performance of the structure.

Image sources- atlis pebsconstructions, built construction, rhino steel building system, adler steel