Fiber reinforcement is an established method for strengthening soil. The present work examines the influence of discrete coir and polypropylene fiber reinforcement (separately) on compressibility parameters of two types of cohesive soils – Soil A (MI-CI) and Soil B (MI). The coir and polypropylene fiber were tested for toughness, tenacity and strain at maximum load. Standard proctor and consolidation tests were performed with the unreinforced and fiber reinforced soils. It was found that with the increase in fiber percentage, optimum moisture content increased whereas maximum dry density decreased for all the cases considered. Also, in case of coir fiber, the value of compression index (Cc) increased upto 0.3% reinforcement and then slightly decreased till 0.5% reinforcement. The same pattern was observed in the case of polypropylene fiber also. For Soil A (MI-CI soil), the maximum values of mv for coir and polypropylene fiber was observed at 0.2% and 0.1% respectively. The maximum value for coefficient of compressibility (av) was observed at 0.5% and 0.3% for coir and polypropylene fiber respectively. For Soil B (MI soil), a continuous increase in Cc was observed with an increase in fiber content (0% to 0.5%) for both types of reinforcement. In case of Soil B (MI soil), the maximum values of av and mv for coir and polypropylene fiber was observed for 0.3% and 0.5% respectively.

1. INTRODUCTION

Ground Improvement is one of the most common methods being used these days for improving the engineering properties and stabilizing the soil at a certain location which is weak to bear and withstand the load of a structure. Many methods have been evolved such as stone columns, soil nailing, vertical drains, reinforced soil etc. Soil reinforcement is one of the oldest ground improvement techniques given by Vidal in 1966.

Various materials also known as stabilizers are added into the soil and adding fiber is amongst one of the most efficient methods. The properties that are usually improved by adding fiber into the soil are compressibility, permeability, shear strength and stiffness. The fiber-reinforced soil behaves as a composite material. When loaded, the fibers mobilize tensile resistance, which in turn imparts greater strength to the soil. The method of fiber reinforcement can be classified into two types, oriented and randomly distributed. In oriented distribution, the fibers are placed in the soil at specific locations and in the other method fiber is mixed randomly into the soil. Random distribution of fibers exhibits some advantages over oriented distribution, and is being used more frequently.

Babu et al. [1] reported the results of experimental investigation using tri-axial shear tests, swelling and consolidation test of black cotton soil reinforced with coir fiber in random manner. The results indicated that by mixing coir fiber in expansive black cotton soil its engineering properties were improved.Estabragh et al. [2] presented the results of an investigation on the effect nylon fiber on the consolidation and shear strength behavior of a reinforced clay soil. A series of one dimensional consolidation and triaxial tests were conducted and the result showed that the pre-consolidation pressure decreased and coefficient of swelling and compression generally increased with increasing the fiber content.Kar et al. [3] studied the impact of short random fiber inclusion on consolidation settlement in local clay and reported that compression index and coefficient of volume change decreased up to certain fiber content and increased thereafter. Mali and Singh [4] studied the strength behavior of cohesive soils reinforced with coir, polypropylene and scrap tire rubber fibers as reported from experimental investigation which includes triaxial, direct shear and unconfined compression tests. Qu and Sun [5] investigated the effects of wheat straw fiber on the consolidation and shear strength behavior of Shanghai clayey soil. The result showed that the pre-consolidation pressure decreased and coefficient of swelling and compression generally increased with the increase in percentage of wheat straw fibers. Subhan [6] discussed the effects of randomly distributed polypropylene fiber on Maximum dry density (MDD), Optimum moisture content (OMC), unconfined compressive strength (UCS), soaked California bearing ratio (CBR) hydraulic conductivity and swelling pressure of an expansive soil. Sathya Priya et al. [7]aimed to study the improvements in properties of clayey soil with high plasticity of Kerala region by adding polypropylene fiber by varying percentage of reinforcements and the soil parameters such as UCS and Dry Density were studied. Bhatt & Varshney [8]studied the use of coir fiber in soil reinforcement. Coir fiber in various percentages were mixed in CL soil of Uttarakhand region and effects on soil properties have been studied through various tests which includes Standard Proctor test, Unconfined Compression test and CBR test.

From past literature, it was found that most of the researchers have worked to determine shear strength and unconfined compressive strength of fiber reinforced soil. But limited study is there for consolidation behavior of soil reinforced with for natural or synthetic fibers coir and polypropylene fiber. This paper presents the consolidation behavior of reinforced clayey soil which in turn checks the secondary settlement. Also, parametric study has been carried out for various consolidation parameters and its inter-dependency.

2. MATERIALS

Two soil samples have been used for the present experimental study. The basic geotechnical properties of soil samples are evaluated and are described in Table 1.

| Properties | Soil A | Soil B |

|---|---|---|

| Specific Gravity | 2.65 | 2.64 |

| Liquid Limit | 39 % | 42 % |

| Plastic Limit | 22 % | 28 % |

| Plasticity Index | 17 % | 14 % |

| IS Classification (IS 1498-1970) | MI-CI | MI |

| USCS (Unified Soil Classification System) | CL | ML |

| Clay % | 45 % | 25.5 % |

| Silt % | 53.24% | 70.48 % |

| Sand % | 1.76 % | 4.02 % |

Table-1: Properties of Soils

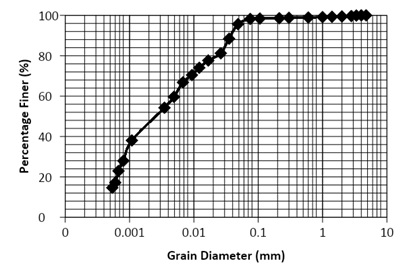

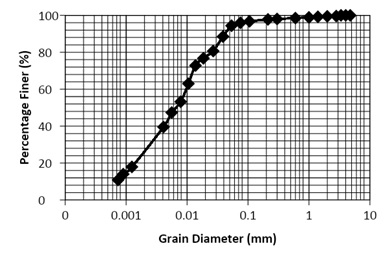

The fibers were cut in 5 mm length and mixed with the soil randomly in various percentages varying from 0% to 0.5% by dry weight (of the soil). Two different types of soils i.e. Soil A and Soil B were defined as MI-CI and MI respectively. The fiber used for reinforcement of soil has been also tested for its tenacity, toughness and some other properties. Figure 1 and 2 represent the Grain Size Distribution curve for Soil A and Soil B respectively. Table 2 presents the properties of reinforcement used.

| Properties | Polypropylene | Coir |

|---|---|---|

| Diameter (mm) | 0.25 | 0.25 |

| Specific Gravity | 0.93 | 1.5 |

| Toughness(MPa) | 792.122 | 719.00 |

| Tenacity(MPa) | 3657.207 | 4060.00 |

| Strain at maximum load (%) | 28.80 | 22.025 |

Table-2: Properties of fiber

3. EXPERIMENTAL STUDY

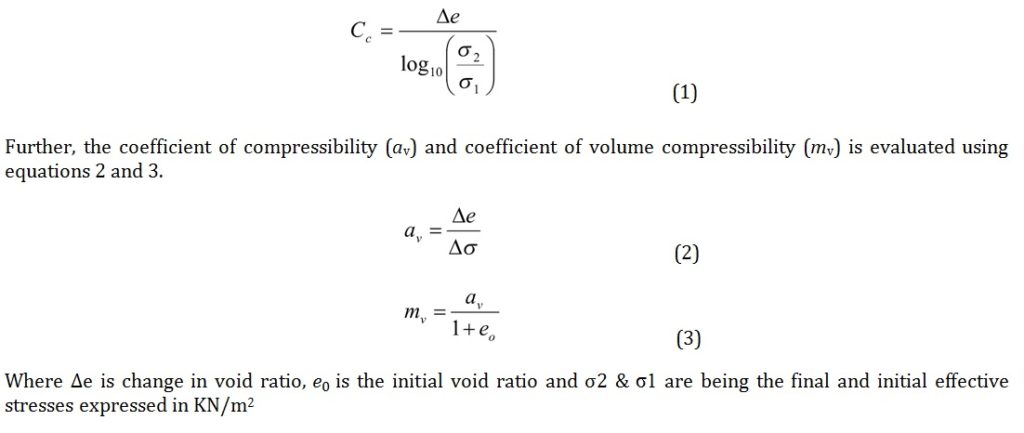

The coir and polypropylene fibers were cut into 5 mm in length and then mixed with both types of soil at various percentages in random and discrete manner. The corresponding OMC and MDD were determined by performing standard proctor tests using an automatic proctor machine. After obtaining the proctor test results the consolidation samples were prepared at OMC and MDD. A series of one dimensional consolidation tests were performed for all the five percentages i.e. 0, 0.1, 0.2, 0.3, 0.5% by weight of fiber reinforced soil. The parameters like Compression index (Cc), Coefficient of compressibility (av) and coefficient of volume compressibility (mv) were evaluated. The equation used to calculated compression index (Cc) is:

4. RESULTS AND DISCUSSIONS

4.1 Experimental Results Of Soil A Reinforced With Coir And Polypropylene Fibers

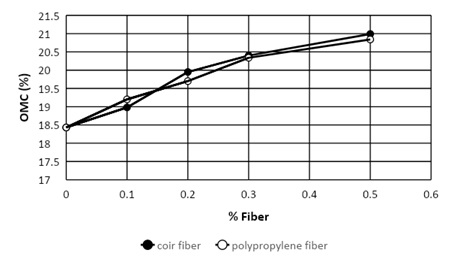

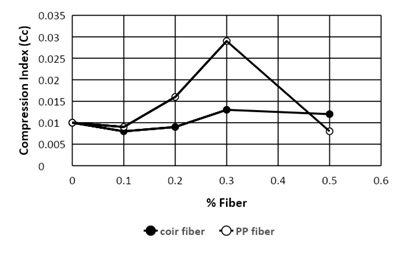

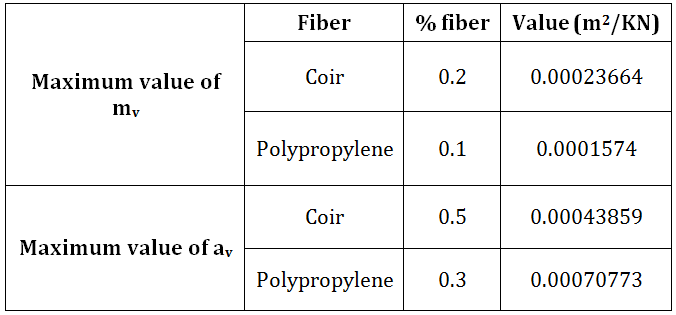

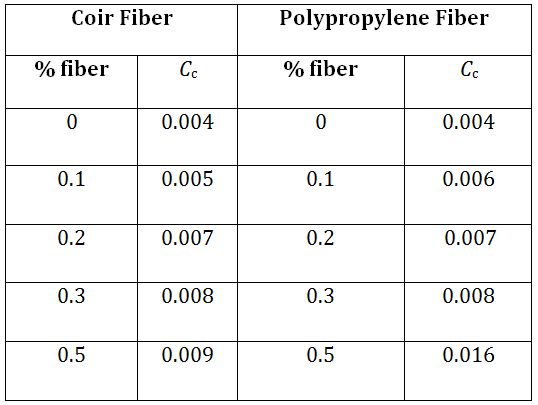

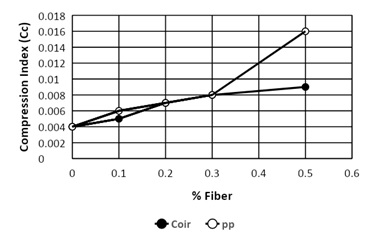

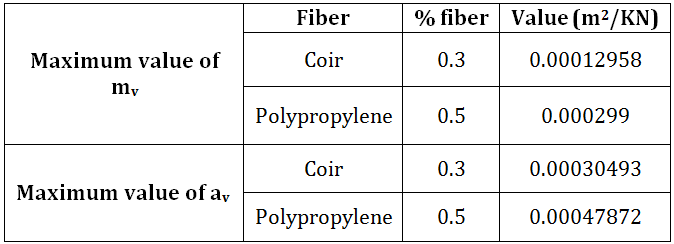

Series of standard proctor and consolidation tests have been performed on reinforced Soil A, results for the same have been shown in Table 3. The trend of % fiber v/s OMC for soil type A has been plotted in Fig, 3. The value of Cc obtained for different percentages of fiber has been presented in Table 4 and the trend of % fiber v/s Cc has been presented in Fig. 4. The maximum values obtained for mv and av corresponding to the percentage fiber mixed has been presented in Table 5 for both the fibers.

| Coir fiber | Polypropylene fiber | ||||

| % fiber | OMC (%) | MDD | % fiber | OMC (%) | MDD |

| 0 | 18.43 | 1.66 | 0 | 18.43 | 1.66 |

| 0.1 | 18.98 | 1.59 | 0.1 | 19.20 | 1.72 |

| 0.2 | 19.95 | 1.57 | 0.2 | 19.70 | 1.68 |

| 0.3 | 20.40 | 1.65 | 0.3 | 20.34 | 1.57 |

| 0.5 | 20.99 | 1.57 | 0.5 | 20.84 | 1.56 |

Table-3: Standard proctor test results for MI-CI reinforced soil

| Coir Fiber | Polypropylene Fiber | ||

| % fiber | Cc | % fiber | Cc |

| 0 | 0.01 | 0 | 0.01 |

| 0.1 | 0.008 | 0.1 | 0.009 |

| 0.2 | 0.009 | 0.2 | 0.016 |

| 0.3 | 0.013 | 0.3 | 0.029 |

| 0.5 | 0.012 | 0.5 | 0.008 |

Table-4: Cc values corresponding to % fiber

4.2 Experimental Results For Soil B Reinforced With Coir And Polypropylene Fiber

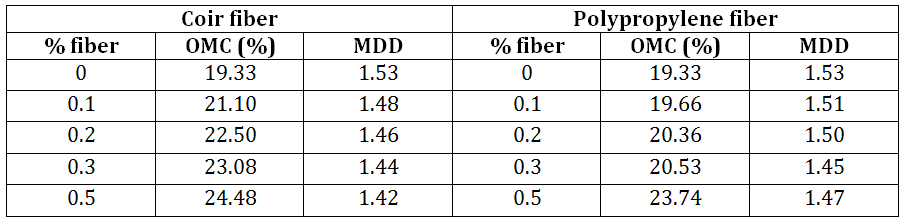

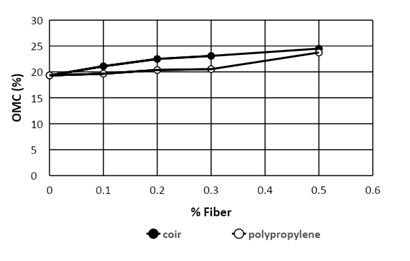

Series of standard proctor and consolidation tests have been performed on fiber reinforced Soil B. The test results for the proctor test have been presented in Table 6. The relation between % fiber and OMC for MI soil reinforced with coir and polypropylene fiber has been presented in Fig. 5. The results of the consolidation test have been tabulated in Table 7 and 8 for Cc and mv & av respectively and the trend for Cc have been shown in Fig. 6.

The test results obtained depicted that as the percentage of fiber increased optimum moisture content also increased, for both the fibers and in both the soil type i.e. MI-CI and MI soils. The maximum dry density (MDD) on the other hand decreased as the % fiber increased. The reason for this increase in OMC for coir fiber can be stated that coir fiber are water absorbent materials and leads to the increase in OMC. Polypropylene fiber when mixed with soil expels water during compaction thus contributes to the increase in OMC at higher fiber content as discussed in Sathya Priya 2017. The results from consolidation test on MI-CI soils depicted that on increasing the percentage of coir fiber the value of compression index (Cc) increased till 0.3% reinforcement and then slightly decreased till 0.5% reinforcement. The same pattern was observed in the case of polypropylene fiber. The consolidation results of MI soil exhibited a continuous increase in the value of Cc as the fiber content increased from 0% to 0.5% for both coir and polypropylene fiber. For MI-CI soil the maximum values of mv for coir and polypropylene fiber was observed for 0.2% and 0.1% respectively. For coefficient of compressibility (av) the maximum value was observed for 0.5% and 0.3% for coir and polypropylene fiber respectively. In case of MI soil the maximum values of av and mv for coir and polypropylene fiber was observed for 0.3% and 0.5% respectively.

5. CONCLUSIONS

As the fiber percentage increased, optimum moisture content increased whereas maximum dry density decreased for all the cases considered. Also, in case of coir fiber, the value of compression index (Cc) increases upto 0.3% reinforcement and then slightly decreases till 0.5% reinforcement. The same pattern was observed in the case of polypropylene fiber also. For Soil B (MI soil), a continuous increase in Cc was observed with an increase in fiber content (0% to 0.5%) for both types of reinforcement. For Soil A (MI-CI soil), the maximum values of mv for coir and polypropylene fiber was observed at 0.2% and 0.1% respectively. The maximum value for coefficient of compressibility (av) was observed at 0.5% and 0.3% for coir and polypropylene fiber respectively. In case of Soil B (MI soil), the maximum values of av and mv for coir and polypropylene fiber was observed for 0.3% and 0.5% respectively. Therefore, it is concluded that on adding the fiber into the soil the value of compression index (Cc) increased especially in case of MI soil which can lead to the increment in settlement, as we know that Cc is directly proportional to the settlement. Further study can be done considering the effect of fiber length and grain size distribution of the reinforcement and soil respectively to evaluate the settlement time for fiber reinforced soil accurately.

REFERENCES

- G.L.S. Babu, Vasudevan, Vasudevan and M.K. Sayida, “Use of coir fibers for improving the engineering properties of expansive soils,” Journal of Natural Fibers, 5(1), pp. 61-75, 2008.

- A.R. Estabragh, A.T. Bordbar and A.A. Javadi, “Mechanical behavior of a clay soil reinforced with nylon fibers,” Geotech Geol Eng., 29(5), pp. 899-208, 2011.

- R.K. Kar, P.K, Pradhan and A. Naik, “Consolidation characteristics of fiber reinforced cohesive soil,” Electronic Journal of Geotechnical Engineering, 17(Bund. Z), pp. 3861-3874, 2012.

- S. Mali and B. Singh, “Strength Behaviour of Cohesive Soils Reinforced with Fibers,” International Journal of Civil Engineering Research, 5 (4), 353-360, 2014.

- J. Qu and Z. Sun, “Strength behavior of shanghai clayey soil reinforced with wheat straw fibers,” Geotech Geol Eng., 34(2 ), pp. 515-527, 2015.

- M.D. Subhan, “Effect of polypropylene fiber in Engineering properties of Expansive soil,” International Journal of Innovative Research Sciene, Engineering and Technology, 5(3), pp. 3680-3684, 2016.

- C.M. Sathyapriya, S. Archana, A.B. Albert and A.D. Deeraj, “Stabilization of clayey soil using polypropylene fiber,” International Research Journal of Engineering and Technology, 4(4), pp. 1252-1255, 2017.

- H. Bhatt and H. Varshney, “Investigation on effect of coir fiber in clayey soil,” International Journal of Advance Research in Science and Engineering, 7(3), pp. 549-555, 2018.

Authors:

Dr. Siddhartha Sengupta, Associate Professor, Civil & Environmental Engineering, Birla Institute of Technology, Mesra, Ranchi – 835215, India.

Sufyan Ghani, Research Scholar, Civil Engineering Department, National Institute of Technology, Patna – 800005, India.