Associate Professor, Civil & Environmental Engineering,

Birla Institute of Technology, Mesra, Ranchi, India

Oil contaminated soil has been defined as any earthen material or artificial fill that hashuman or natural alteration of its physical, chemical, biological or radiological integrity resulting from introduction of crude oil, any fraction or derivative thereof (such as gasoline, diesel, or used motor oil) or any oil based product. Oil waste dumping, production, pollution, and spills wreak havoc on the surrounding. Geotechnical engineers are faced with increasing challenges as a result of oil spills and hence the need for laboratory studies involving oil contaminated soils. A lot of work has been already done using the above soil. Also, it may be noted that variation in compactive energy changes the behaviour of soils in general. In the present study efforts have been made to observe the compressibility of cohesive soil contaminated with diesel in varying proportions under three different compaction energy levels.

Experimental study

Classification of soil

Locally available soil is used in the investigation. The index properties (for soil with 0 % oil) along with the compositions of the soil are shown in Table 1.

Table 1: Properties of soil

| Properties | Value |

| Specific gravity | 2.715 |

| Liquid limit | 42.50 % |

| Plastic limit | 26.58 % |

| Plasticity index Maximum dry density Optimum moisture content Clay content Silt content Sand content | 15.92 % 1.670 g/c.c. 19.60 % 33.50 % 54.20 % 12.30 % |

As per USCS and IS: 1498 the soil is classified as “ML” and “MI” respectively. Locally available diesel oil was used in the study. The properties of oil are tabulated in Table 2 below.

Table 2: Properties of oil

| Properties | Value |

| Density (at 25º C) | 0.815 g/c.c. |

| Pour point | (-) 8º C |

| Kinematic Viscosity (at 26º C) | 0.0567 poise |

| Kinematic Viscosity (at 38º C) Flash point Fire point | 0.0411 poise 77°C 94°C |

Preparation of soil samples

After collection the soil lumps were broken into small pieces and screened through 4.75 mm size sieve to make it free from roots, pebbles etc. Then the soil samples were dried in oven at 105ºC for 24 hours. After that the samples were mixed with diesel oil in the amount of 0, 3, 6, 9 and 12 % by weight of the dried soil. The above range of contaminant oil was chosen in accordance with the observed level of contamination found. The mixed samples were put into closed containers for 1 month for aging and equilibrium, allowing possible reactions between soil and the oil.

Proctor tests

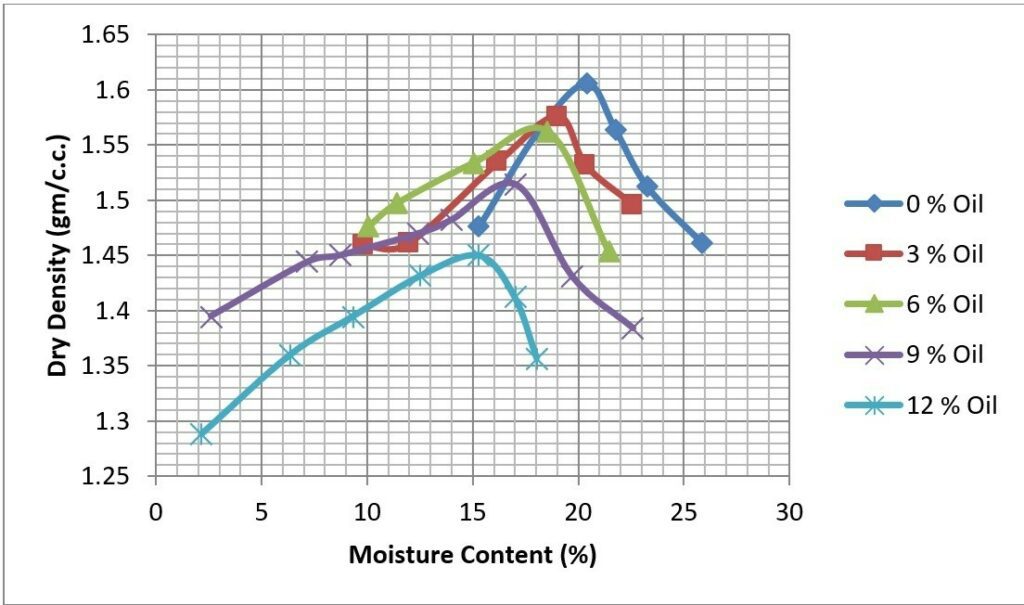

Reduced Proctor, Standard Proctor and Modified Proctor compaction tests were carried out with the soil having oil contents of 0, 3, 6, 9, and 12 %. Typical dry density-moisture content curves for different oil contents are shown in Figure 1. The compaction curves for the contaminated soils generally moved to the left side and downward of the uncontaminated soil curve as the oil content increased. A drawdown trend was noticed in the optimum moisture content value with increasing oil content. It implies that the water content needed to achieve maximum dry density decreased when oil content increased. It is probably attributed to the lubricating effect of oil. Maximum dry density dropped significantly for increase in oil content. This decrease in maximum dry density could be attributed to the fact that oil had partially occupied the soil particle interstitial spaces which resulted in some loosening of the soil matrix. This reflects the lubricating effect caused by the presence of oil, which facilitates compaction and reduces the amount of water needed to reach maximum density.

Consolidation tests

Consolidation test of uncontaminated as well contaminated soils were performed by preparing samples using three different compactive efforts (reduced proctor, standard proctor, and modified proctor). Parameters such as compression index (Cc), coefficient of volume change (mv) were determined from the data obtained by experiments.

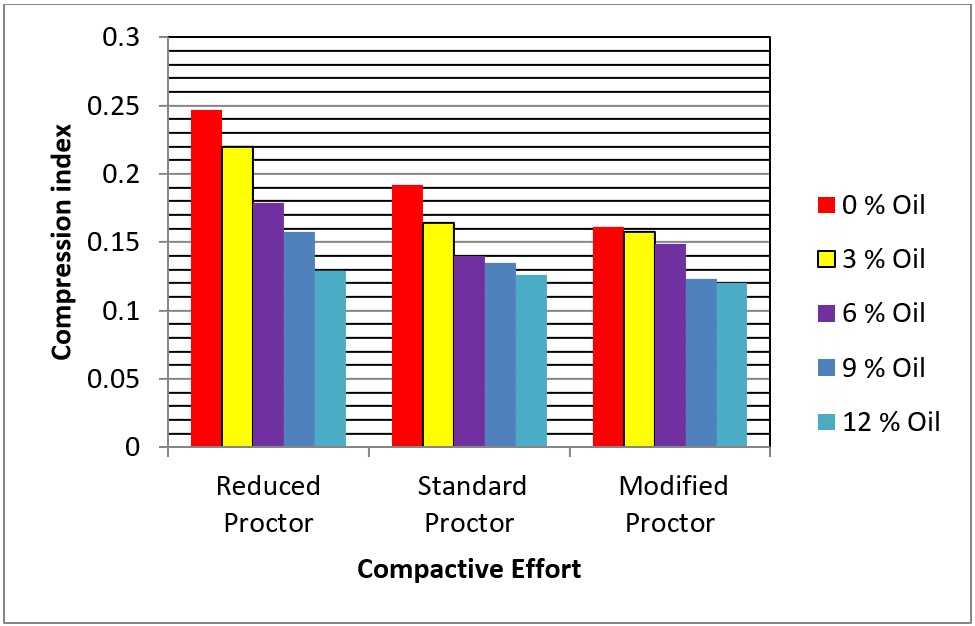

It may be seen from Figure 2 that compression index (Cc) decreased with the increase in oil content. This reduction can be explained using the surface energy available at the oil-water interface. This surface energy provides a large surface tension at the interface that is able to join together the water droplets and reduce the water drainage, which lead to lower compression index. Also, it was found that compression index generally decreased with increase in compactive effort irrespective of the oil content. Increased compactive effort results in a more compact state of soil which concurrently leads to diminishing compressibility.

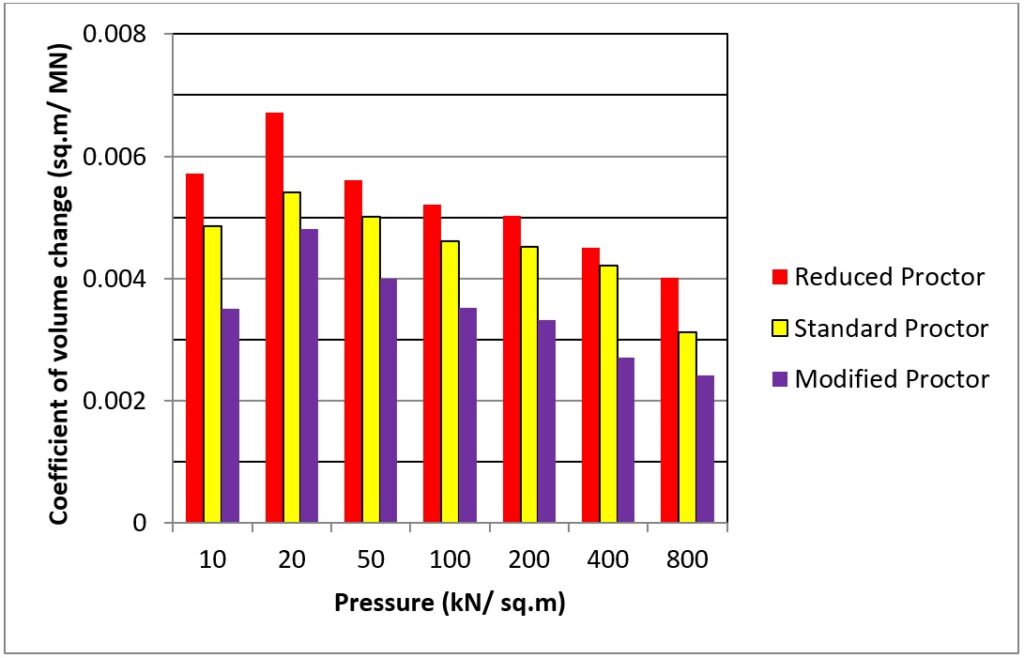

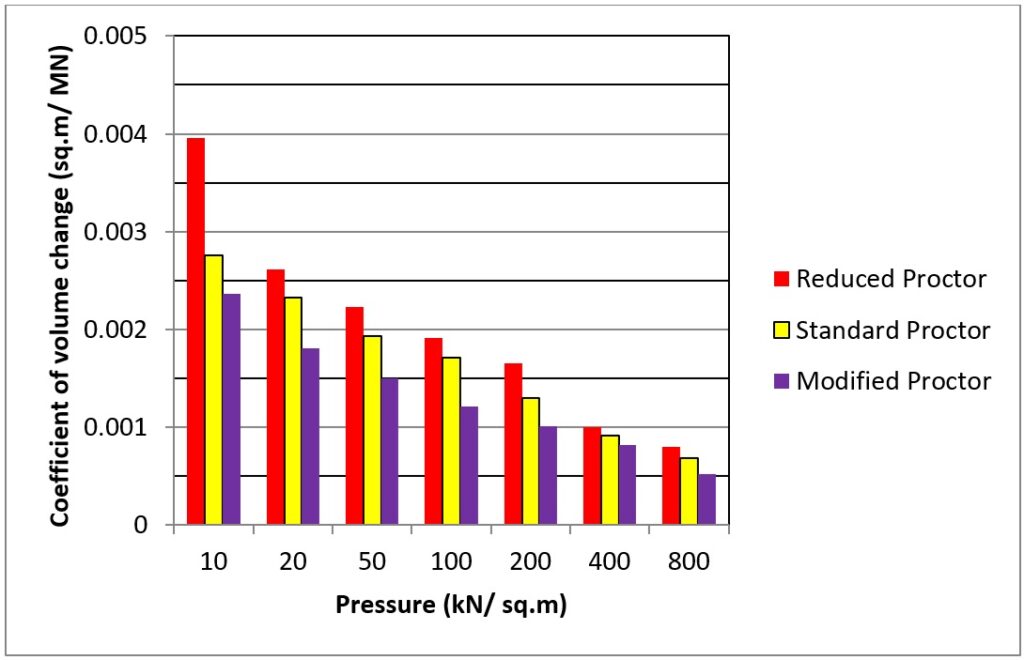

Typical variations of coefficient of volume change (mv) values at different levels of oil contamination under varying compactive efforts are shown in Figures 3 and 4. It was observed that for all the cases corresponding to a particular value of pressure, the magnitude of mv decreased with increase in oil content. This could happen due to presence of fewer voids at higher oil contents as a more bonded soil matrix was formed with higher content hence the contaminated soil experienced little compression. Also, it was found that for levels of compactive efforts, corresponding to 0 %, 3 %, 6 % oil contents the value of mv increased on increasing the loading pressure from 10 to 20 kN/m2. This might happen due to greater void spaces available at the early stage of loading. On increasing the pressure further, the magnitude of mv went on diminishing. The probable reason could be as a result of higher weights and no available void to undergo compression. Corresponding to 9 % and 12 % oil, there was no initial increase of mv (on increasing the pressure from 10 to 20 kN/m2) and it continuously decreased. The reason for the above may be is that the at comparatively higher oil contents the voids (hence the space to be compressed) became reduced. Also, except a few cases [(i) Reduced Proctor, 800 kN/m2 pressure, 12 % oil content; (ii) Standard Proctor, 50 kN/m2 pressure, 12 % oil content] irrespective of the pressure applied and oil content, the coefficient of volume change reduced with increase in compactive effort. This happened due to increase penetration by the compaction rammer on the soil surface resulting in closer alignment/packing of soil fabric

Conclusions

Changes in optimum moisture content and maximum dry density were found of diesel contaminated cohesive soil. Consolidation tests were carried out with samples prepared by compacting the soil with different compactive efforts. Compression index of the contaminated soil was found to decrease with increasing compaction energy. For soil having comparatively lower percentage of oil, the coefficient of volume change initially increased with pressure and later decreased. For soil with higher oil content, the corresponding coefficient of volume change decreased continuously with increase in pressure. The result of the present research shall be useful in design and construction of structures where oil spillage has occurred. In an upcoming research article the application methods of the research will be covered.

References

- Eberemu, A.O., Omajali, D.I., Abdulhamid, Z. . “Effect of compactive effort and curing period on the compressibility characteristics of tropical black clay treated with rice husk ash.”

- Ijimdiya, T.S., Igboro, T. . “The compressibility behaviour of oil contaminated soils.” Electronic J of Geotechnical Eng (EJGE), Vol. 17

- Khosravi, E., Ghasemzadeh, H., Sabour, M.R., Yazdani, H. . “Geotechnical properties of gas oil-contaminated kaolinite.” Eng. Geol., 166, 11-16.

- Nasehi, S.A., Uromeihy, A., Nikudel, M.R., Morsali, A.“Influence of gas oil contamination on geotechnical properties of fine and coarse-grained soils.” Geotechnical and Geological Engineering

- Rahman, Z.A., Hamzah, U., Taha, M.R., Ithnain, N.S., Ahmad, N. . “Influence of oil contamination on geotechnical properties of basaltic residual soil.”

About the author

Dr. Siddhartha Sengupta has published a number of research papers in national and international journals, and worked as the principal investigator in four sponsored research projects. He has supervised eleven postgraduate theses till date. Also, he is a member of different professional bodies such as IEI, ISTE, IGS, ISSMGE. The author graduated (Civil Engineering) from University of North Bengal in the year 1998. He completed M.E. in Civil Engineering (specialization – Soil Mechanics & Foundation Engineering) in 2000 from Birla Institute of Technology, Mesra, Ranchi. In 2005, he obtained his Ph.D. in Civil E