Imagine a world where roads are not just paths, but canvases of creativity, where sidewalks are more than mere pathways, but intricate designs etched into the urban landscape. This vision comes to life through the remarkable innovation of the paver block machine. In this article, we delve into the paver block machines, exploring their types, features, diverse applications, and the impact they have on shaping our modern infrastructure.

What is a paver block machine?

A paver block making machine is a mechanical device used in construction and landscaping to produce interlocking concrete or brick-like blocks, commonly known as paver blocks. These blocks are designed for creating durable and visually appealing paved surfaces, such as roads, walkways, driveways, patios, and other outdoor areas. The machine combines raw materials like cement, sand, aggregates, and additives, mixes them into a concrete mixture, compacts the mixture within a mold, and then releases the formed paver blocks. Its main components typically include a hopper for holding raw materials (such as cement, sand, and aggregates), a conveyor system for feeding the mixture into molds, a hydraulic or mechanical press for compacting the mixture, and a control panel for operating the machine.

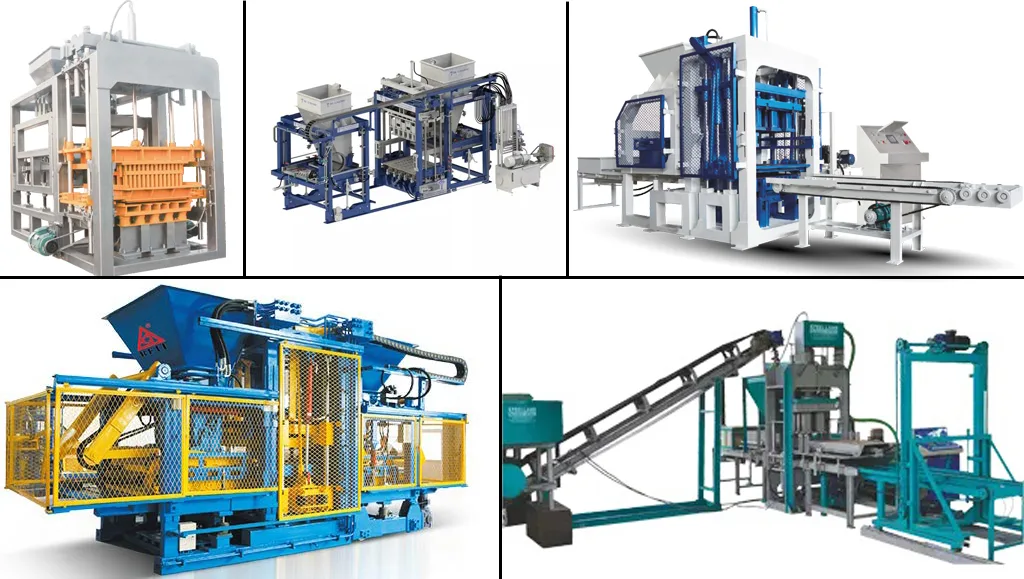

Types of paver block making machines

Paver block making machines come in various types and designs, each catering to different production capacities, levels of automation, and specific features. Here’s a comprehensive overview of some common types of paver block making machines:

- Manual Paver Block Making Machine: These are simple and manually operated machines suitable for small-scale production. They require human effort for material mixing, filling molds, compacting, and demolding.

- Semi-Automatic Paver Block Making Machine; These machines automate certain aspects of the process, such as material feeding and block compression. They often have a vibrating table to enhance block compaction.

- Fully Automatic Paver Block Making Machine; These advanced machines are highly automated and require minimal human intervention. They can handle the entire process, including material mixing, feeding, compression, and block ejection, through computerized controls.

- Hydraulic Paver Block Making Machine: This type of machine utilizes hydraulic pressure to compact the concrete mixture within the mold. Hydraulic systems offer precise control over pressure and allow for consistent block quality.

- Mechanical Paver Block Making Machine: Instead of hydraulic pressure, these machines use mechanical mechanisms like levers and cams to apply force for compacting the concrete mixture.

- Vibro-Hydraulic Paver Block Making Machine: This combines hydraulic pressure with vibration mechanisms for optimal compaction and air bubble removal within the concrete mixture.

- High-Pressure Paver Block Making Machine: These machines apply higher levels of pressure during compaction, resulting in denser and stronger paver blocks.

- Interlocking Paver Block Making Machine: Specifically designed for producing interlocking paver blocks with unique patterns and designs that fit together securely.

- Concrete Paver Block Making Machine: This type of machine is specialized for producing concrete paver blocks with various shapes, sizes, and textures.

- Fly Ash Brick and Paver Block Making Machine; These machines are designed to utilize fly ash, an industrial waste product, as a raw material in combination with cement, producing environmentally-friendly paver blocks.

- Mobile Paver Block Making Machine: These machines are mounted on wheels, making them portable and suitable for on-site production.

Features of paver block making machines

Paver block making machines come with a range of features that enhance their functionality, efficiency, and versatility. Here are some common features you might find in these machines:

- 1. Multiple Mold Options: Allow for the use of different molds, enabling the production of various paver block designs, sizes, and patterns.

- 2. Interchangeable Molds- Offer easy mold interchangeability, allowing you to switch between different mold types quickly.

- 3. Vibration System: A vibration mechanism ensures better compaction of the concrete mixture, resulting in denser and more durable paver blocks.

- 4. Hydraulic System: Provides precise compaction and consistent block quality.

- 5. Automated Material Feeding: Enhance efficiency and reduce labor requirements.

- 7. PLC (Programmable Logic Controller); PLC-based control systems for precise and automated operation.

- 10. Pressure Adjustment; Offer adjustable pressure settings to accommodate different types of raw materials.

- 11. Automatic Ejection: Fully automatic machines can automatically eject finished paver blocks from the molds.

- 12. Safety Features; Equipped with emergency stop buttons and protective covers ensure safe operation.

- 13. Customization Options- Allow for customization of block colors, sizes, and textures.

It’s important to choose a machine with features that align with your production needs and project requirements. The specific features available may vary based on the manufacturer, model, and type of paver block making machine.

Applications of paver block making machines

The paver block making machine finds diverse applications due to its ability to produce interlocking concrete or brick-like blocks. Here are some key applications of the paver block making machine.

- Road Construction

- Sidewalks and Walkways

- Driveways

- Parking Lots

- Patios and Courtyards*

- Landscaping

- Plazas and Public Spaces

- Commercial and Residential Complexes

- Industrial Facilities

- Pool Decks

- Golf Courses

- Pedestrian Zones

- Public Gardens etc.

Paver block machines demand in India

The demand for paver block making machines in India has been on the rise due to several significant factors that have shaped the construction and infrastructure landscape in the country. The demand is driven by:

- Urbanization and Infrastructure Development: India’s growing population and urbanization have led to increased demand for better infrastructure, including roads, walkways, driveways, and pavements. Paver blocks are a popular choice for these applications due to their durability and aesthetic appeal.

- Government Initiatives: Government-led initiatives such as “Smart Cities Mission” and “Housing for All” have fueled the need for high-quality and sustainable construction materials, making paver blocks a preferred choice.

- Environmental Concerns: Paver blocks are environmentally friendly as they promote water infiltration, reduce stormwater runoff, and minimize heat absorption compared to traditional pavements. This aligns with the growing emphasis on sustainable construction practices.

- Rise in Real Estate Sector: The growth of the real estate sector, including residential, commercial, and industrial projects, has driven the demand for quality construction materials, including paver blocks.

- Demand for Customization: Paver blocks can be customized to suit specific project requirements, allowing architects and designers to create unique and attractive designs.

- Infrastructure Upgradation**: Existing infrastructure in many urban areas is undergoing upgradation and renovation, creating a need for reliable and durable pavement materials like paver blocks.

- Reduced Labor Dependency Paver block making machines automate the production process, reducing the dependency on manual labor and increasing overall efficiency.

- Construction Projects of Various Scales: Paver blocks are used in a wide range of projects, from small residential pathways to large-scale urban roads and plazas.

These factors collectively contribute to the increasing demand for paver block making machines in India as the construction industry seeks more efficient, sustainable, and cost-effective solutions.

Conclusion

The paver block machine plays a crucial role in modern construction, offering efficient and precise production of durable paving blocks. Its automated capabilities, versatile design, and environmental benefits make it a valuable asset for the construction industry. As technology continues to advance, we can expect further innovations in paver block machine technology, enhancing its performance and contributing to sustainable infrastructure development.

Image Source: brickwell.in, armixmachinery.com, qgreentech.com, chiragint.com, steellandmachineryworks.com