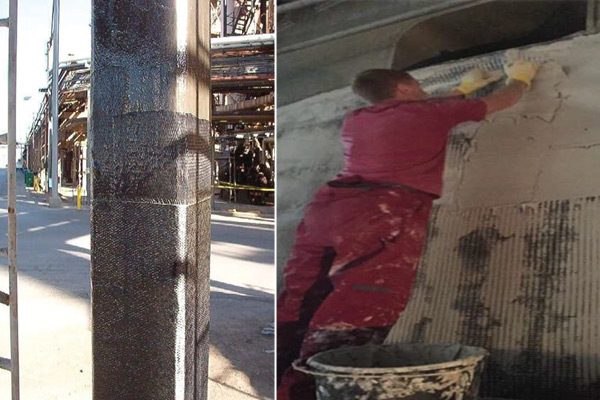

A building may require rehabilitation and strengthening due to upgrading of design standards, increased safety requirements, change in its function, loads can increase or higher building standards become required and the structure must be made compliant. s. Due to excessive load, exposure to toxic environments & abuse, these buildings get deteriorated with time. This creates an ultimate necessity for restoration to make the existing structural members safe. In such scenarios appropriate method and material is a prerequisite to regaining their structural strength. One such method is carbon fiber wrap. The method uses Fiber Reinforced Polymers in the form of thin laminates or fabrics. Unlike traditional retrofit or reconstruction techniques, carbon wrap goes right over the existing substrate. This minimizes disruption during repair and saves significantly on installation time and costs. Carbon fibre has very high tensile strength and is also very lightweight. When bonded to the exterior of a concrete column, beam, or slab, it can add significant strength without adding weight that would increase the load on foundations and other structural members.

Advantages of Carbon Fiber Wrapping

Carbon Fiber Wrapping System provides significant strength to structures and protects against further corrosion and erosion. The impervious material will protect a structure from moisture intrusion and further corrosion, reducing the need for ongoing maintenance work. Carbon fiber has extremely high elasticity and is additionally lightweight. When clung to the outside of a solid segment, pillar, or piece, it can include critical quality without including weight that would expand the load on establishments and other structural individuals.

The system consists of Carbon fiber that is made of thin, strong crystalline filaments of carbon that is used to strengthen the material. Carbon fiber can be thinner than a strand of human hair and gets its strength when twisted together like yarn. Then it can be woven together to form cloth and if needed to take a permanent shape, carbon fiber can be laid over a mold and coated with resin.

Carbon fiber reinforced polymers are made up of carbon fiber for strength and reinforced polymer as the cohesive matrix, or the glue, that binds the fibers tightly together – also providing protection and resilience. It is used for strengthening concrete columns and beams. Carbon fiber wrapping is not only used in repairs, it can also be used in new construction, to both increase structural load and also provide long-term protection.

Taking into account the limitations and potential challenges of conventional method of strengthening, Relinforce™ product lines can be used to rehabilitate and strengthen the damaged or deficient concrete structures to take the designed loads with the use of carbon wrap technology. Relinforce™ system comprises high-strength carbon fabric fully saturated with an appropriate resin system or precured laminates to provide required additional strength to any damaged structure.

Relinforce™ for Industrial and Commercial Buildings

Relinforce™ just doesn’t repair degraded structures, but it makes the structures stronger even against harmful effects of seismic forces or further corrosion. Unlike traditional retrofit or reconstruction techniques that require demolition and reconstruction of part or whole failing structures, Carbon wrap goes right over the existing substrate, minimizing disruption during repair and saving significantly on installation time and costs.

About Relinforce™ Carbon wrap & Glass Fiber-reinforced polymer products

Relinforce™ range of Carbon wrap & Glass Fiber-reinforced polymer products are manufactured and supplied under Reliance India’s Composites Solution Division. Reliance Industries Limited is India’s largest private and one of the most profitable private sector companies and the first Indian Fortune 500 company.

Relinforce™ product range is used for structural strengthening & protection of the structural members using guidelines that conform to international standards. These products just don’t repair degraded structures, but it makes the structures stronger even against harmful effects of seismic forces or further corrosion. There is a wide range of products combined with outstanding combinations of properties, such as low weight, immunity to corrosion, excellent mechanical strength and stiffness to tackle the issues on hand with ease.

To know more about the product, visit- https://www.reliancecomposites.com/