Scaffolding is a temporary structure used by workmen when renovating, maintaining, repairing or cleaning a building that aims to keep them safe, give them easy access and allow for improved efficiency. It consists of one or more planks of convenient size and length, with various methods of support, depending on the form and use.

Types of Scaffolding Used in Construction:

Single Scaffolding

Single scaffolding is usually used for brick masonry and so it is also known as brick layer’s scaffolding. Single scaffolding comprises standards, putlogs, ledgers etc., which corresponds to the wall at a distance of around 1.2 m. The distance amongst the standards is around 2 to 2.5 m. Ledgers join the standards at an upright gap of 1.2 to 1.5 m. Putlogs are extracted from the gap remaining in the wall to one end of the ledgers. Putlogs are positioned at a gap of 1.2 to 1.5 m.

Double Scaffolding

Double scaffolding differs from single scaffolding in that it features two rows of standards separated by ledgers for better support. Notice that a single row of standard is normally fixed to the ground in the case of brick layer’s scaffolding.It is widely used for stone masonry works. This scaffolding type is generally stronger and provides better support for construction works. It is commonly used for stone masonry because it is hard to make holes in stone walls to support putlogs. Instead, two rows of scaffolding are required, the first is fixed close to the wall and the second is fixed some distance from the first. Then, putlogs are supported at both ends on ledgers making them completely independent of the wall surface.

Cantilever Scaffolding

Cantilever scaffolding is a form of scaffolding that is usually used to overcome obstacles that prevent a scaffolding tower from being erected or reduce the chances or damage occurring to the structure beneath the cantilevered area. It is used when obstacles are preventing a scaffolding tower being erected such as the ground can’t support standards, the ground near the wall needs to be free from traffic or the upper part of the wall is under construction. It is also used when there is no hard firm ground to support the standards, for instance, when construction work is carried out on busy streets and where the construction work is done at great heights on a multi-storied building.

Suspended Scaffolding

Suspended scaffolding consists of a platform suspended from above by cables and stirrups on each side of the platform or a single basket with one motor. It is a working platform that is suspended from a roof with wire rope or chains and can be lifted and lowered when needed. This is ideal for painting, repair works and window cleaning – all jobs that may take a day or less to complete and only require a platform and easy access.

Trestle Scaffolding

A trestle scaffold is assembled from prefabricated trestles, braces and accessories. Trestle scaffolds, for example ‘A-frame’ and ‘H-frame’ trestle scaffolds, are commonly used by bricklayers, plasterers and painters and for general fit-out and finishing work. Trestle scaffolds generally do not require a licensed scaffolder to erect or dismantle. A trestle scaffold is a scaffold assembled from prefabricated trestles, braces and accessories. Trestle scaffolds, for example ‘A-frame’ and ‘H-frame’ trestle scaffolds, are commonly used by bricklayers, plasterers and painters and for general fit-out and finishing work. Trestle scaffolds generally do not require a licensed scaffolder to erect or dismantle.

Steel Scaffolding

Steel scaffoldings are temporary platforms, either supported from below or suspended from above, on which workers stand while doing jobs at heights above the ground level. Building & construction jobs may require several kinds of scaffolds to permit easy working. Steel Scaffoldings may range from singular planks placed on structural members of the building to involved patent scaffolding.Steel scaffolding is made from steel tubes that are set jointly by steel fittings or couplers. It is simple to erect and to dismantle. It has better robustness, greater durability and superior fire resistance.

Patented Scaffolding

Patented scaffolding is made of steel but used special couplings and frames so that it can be adjusted to the required height. These are easy to assemble and take down and more convenient for short-term works such as repairs. This type of scaffolding working platform is arranged on brackets that can be adjustable to our required level.

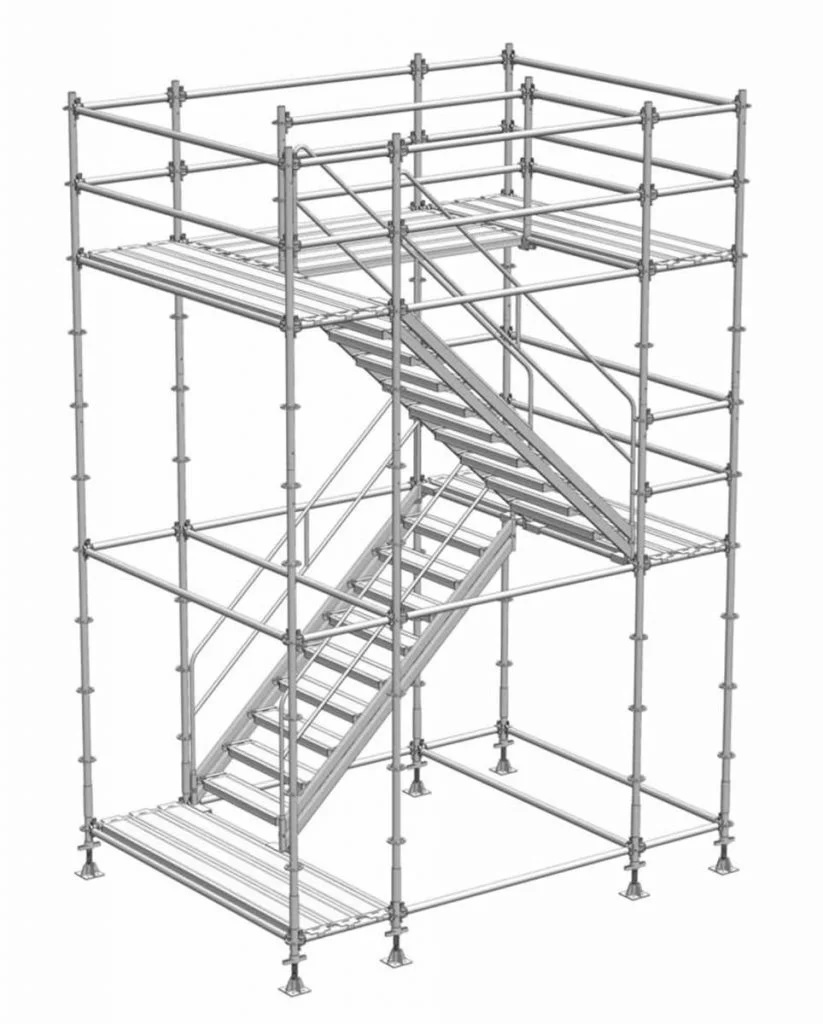

Access Scaffolding

Access scaffolding is designed to provide temporary access to hard-to-reach places on large construction sites. This type of scaffolding is available in a selection of different systems such as ring-loc systems, tube & clamp, and frame scaffold and stairway towers for construction access and public use. Its purpose is to help construction works gain access to hard-reaching areas of a building. It’s typically used for general maintenance and repair work.

Conclusion

Discussed above are different types of scaffolding systems, their advantages and applications. In upcoming articles we will focus on each specific scaffolding types.