Aluminium Composite Panels are sandwiched panels that have layers of aluminium sheets with the polyethylene core. It is composed of combustible or non-combustible thermoplastic material used in the exterior and interior of the buildings. These composite panels are manufactured from two aluminium sheets that are well bonded to a non-aluminum core. Aluminium composite panels can be utilised in every type of building. The main purpose of the panels is to support the dead wall and provide aesthetics to the elevation of the building. Aluminum composite panels are also for flat aluminum bars to enhance its durability.They are available in different colours, different sizes and different shapes.

Aluminum composite garage doors are perfect for modern homes, offering a sleek and contemporary aesthetic. Their aluminum and composite materials combination creates a lightweight yet durable structure, ensuring longevity and low maintenance. The smooth surface of these doors can be customized with various finishes, colors, and textures, allowing homeowners to achieve their desired look. With their excellent insulation properties and resistance to warping or fading, aluminum composite garage doors provide style and functionality for the modern homeowner

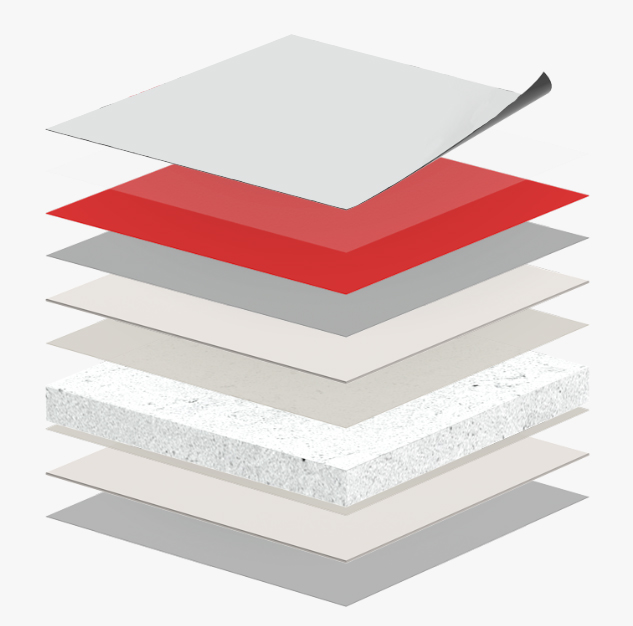

Composition of aluminium composite panels

Lamination process is adopted to manufacture the aluminium composite panels. Its top and the bottom layers are of coated aluminium sheets and the core sandwiched between them is polyethylene. It comprises of;

- Protection Film

- PVDF/Polyester Resin Based Coating

- Primer Coating

- Aluminium Coil

- Adhesive Film (Polyolefin)

- Polyethylene Core (LDPE)

- Adhesive Film (Polyolefin)

- Aluminium Coil

- Service Coating (Anti-corrosive)

Advantages of aluminium composite panels

The aluminium is lighter than other cladding panel materials. When it is exposed to air it forms a special layer of aluminium oxide which protects the panels from rusting and corrosion. Aluminium composite panels are subjected to the process called anodization which increases aluminium panel thickness. Aluminium material are unaffected even exposed to moisture and sunlight which is a major advantage of using it. Its advantages include;

- Can bend, fold and turn easily

- Flatness

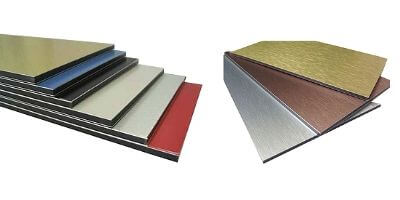

- Wide range of colours and finishes

- Excellent thermal and acoustic insulation

- Borer, termite, and fungi resistant

- Available in different thicknesses

- Can be made fire retardant

- Have antimicrobial properties

- UV ray resistant

- Lightweight and corrosion and shock resistant

- Environment-friendly

- Fully recyclable

- Withstands extreme weather conditions

- Easy to clean

- Easy to perforate

- Earthquake resistant

Types of aluminium composite panels

Fire Retardant ACP

A Fire Retardant ACP sheet is made in the form of a honeycomb design that brings down the intensity of the fire and the heat produced from any fire outbreak. The air bubbles situated between the honeycomb design ensure to trap the fire by creating a vacuum in between the layers.

Non-Combustible ACP

It is the same as a traditional composite panel; however, what makes it different is the technology of the core, which is constructed from a 100% aluminium structure rather than any combustible material. It is made of an advanced mineral compound that is best for restraining the flammability of the minor polymeric content and restricting flame propagation and smoke generation.

Anti-Bacterial ACP

Anti-bacterial ACP sheets actively shield you and your loved ones from harmful bacteria such as coliform, staphylococcus aureus, salmonella, enteritis bacteria etc.

Based on thickness;

3mm ACP

Aluminium Composite Panels having 3mm thickness, it has two layers of Aluminium both over and beneath the core. The thickness ensures longevity, as well as the thickness, being ideal both for exterior and interior applications.

4mm ACP

ACP sheets that boast a 4mm thickness are ideal to have multiple use cases, including both interior and exterior applications.

6mm ACP

6mm ACP sheets can withstand not only extreme temperatures but also are water-resistant. They can also actively resist mold, swelling, and rusting.

Different shapes of aluminium composite panels

An aluminium composite panel can be transformed in many ways.Different shapes can be created with

- Punching and die-cutting

- Roller bending

- 3D Forming

- Edging

- Stamping and engraving

- Milling

Installation of aluminium composite panels

- ACP panels are first mounted on other plastic aluminium plates or other materials with rivets, bolts, screws, or nails, made of aluminium or stainless steel

- Before attaching ACP panels to different materials (like steel plates), at least a 25u-thick layer of insulating and galvanized material

- All joints should be of specified widths. No two adjacent or perpendicular joints should have a difference in width of more than 2.5 mm.

- By adhering one side of the angle material to the bent edge of the ACP panel with strong structural glue

- Attaching the middle of the angle with rivets, a prefabricated panel for the upper wall will be created

- Supporting brackets should be designed to provide three-dimensional adjustments and accurate location of wall component

- Join the prefabricated ACP panels block by block by adjusting them to the same level and sealing them with rivets and self-tapping screws

Applications of aluminium composite panels

- Exterior – façade, canopy, overhang, soffit and more.

- Interior – wall covering, false ceiling, cupboards, wardrobes, modular kitchens, table tops, column covers and more.

- Corporate Identity Design – Signage, kiosks, totems, POPs, fascia, etc.

- For cladding all types of facades.

- For covering columns.

- Balcony cladding.

- Canopies, tunnels, subway interiors, telephone booths, column covers or renovations

Conclusion

The aluminium composite panel has changed the design architecture, as the ACP panels are easy to fabricate and install in any commercial and residential complexes. The aluminium panel sheets bring an essence of opulence as wall elevation. Aluminium Composite Panels is one of the preferred new-age materials for architects and designers. Owing to its numerous advantages such as lightweight, great texture, tone, and affordability, aluminium composite panels are in high demand.

Analysis of Aluminium Composite Panels

Composition of aluminium composite panels

Advantages of aluminium composite panels

Types of aluminium composite panels

Different shapes of aluminium composite panels

Installation of aluminium composite panels

Applications of aluminium composite panels