The self-loading concrete mixers in India amid the government’s push for mega infra projects including rural & agri infra development. They are being widely used in all the above sectors and considering the thrust given by the Govts. across the country the demand for SLCMs is poised to witness more technical advancement in the machine.

Constrofacilitator had a one-to-one conversation with Ajay Aneja, Chief Marketing Officer, AJAX Engineering, wherein he shared insights on the importance of productivity, concrete mix quality, financial benefits over conventional mixing methods, potential of self-loading concrete mixers and much more.

“AJAX ARGO Self-Loading Concrete Mixer (SLCM) delivers ‘Maximum Productivity for Your Investment’ says Ajay Aneja, Chief Marketing Officer, AJAX Engineering.

Here are the excerpts of the interview

1. How do you see the demand for self-loading concrete mixers in India amid the government’s push for mega infra projects including rural & agri infra development?

The Construction Equipment Sector has witnessed a good revival after the pandemic situation from 2020. Construction sector is poised for good growth in FY2022 due to a strong pipeline of projects and various government measures aiding growth. The investments planned under the National Infrastructure Pipeline (NIP) will be key growth drivers for the construction sector. While the execution was severely impacted in H1FY2021 due to the nationwide lockdown, reverse migration of labour and supply-chain constraints. In the last few months, the Centre has announced a slew of relief measures to support players, including relaxation on EMD (earnest money deposit) and performance security, relaxation of bidding eligibility criterion and increased frequency of payments for government tenders.

As a result, today with the increasing number of Tender Awards and other large scale projects like the Expressways, Bullet Train Project and other Mega Railway and Metro projects, the order book position of most of the construction players is growing. This along with focus on upgradation of existing rural roads from Pradhan Mantri Gram Sadak Yojana (PMGSY) scheme, Smart City Projects, Rural Housing scheme such as Pradhan Mantri Awas Yojana (PMAY) have increased the demand of Self-Loading Concrete Mixer (SLCM), Small Batching plants and Pumps.

Agri Infrastructure plays a vital role for the economy of the country. The Infrastructures such as Irrigation, road connectivity, electrification & storage facilitates farmers in the process of sowing to sell.

SLCMs are widely used in all the above sectors and considering the thrust given by the Govts. across the country the demand for SLCMs will sustain in the years to come and the industry will witness more technical advancement in the machine.

2. What are the main application areas where self-loading concrete mixers can play a major role, bringing efficiency and operational economy at the project sites; please elaborate on its productivity, concrete mix quality, financial benefits over conventional mixing methods?

AJAX was the pioneer in bringing the concept of SLCM in India way back in 1992 and revolutionised the way of concreting in project sites.

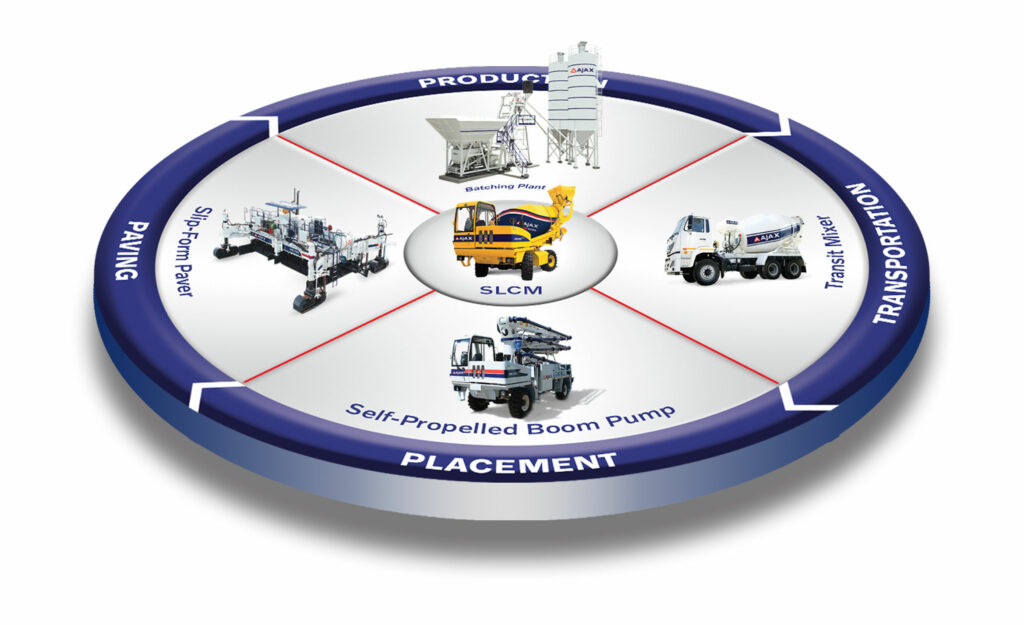

Today, these machines find its application in Irrigation, Roads, Bridges, Railways, Airport Infrastructure, Power Transmission projects, Renewables Energy projects – Wind farm/ Solar Park projects, Urban Infrastructure Development – Skywalks, Metro Rails/ Fly-overs etc., to name a few.

Today, AJAX is India’s largest SLCM manufacturer with over 19,000 SLCMs that are working satisfactorily across the length & breadth of the country in varied applications with the wide spectrum of business segment expertise.

AJAX ARGO SLCM is best suited for small and medium concrete volume requirements across varied applications. These machines are available in different capacities ranging from 3m³/hr. to 14m³/hr. concrete output based on site conditions.

The smart Concrete Batch Controller (CBC) fitted in this machine ensures the right quantity of materials are fed into the drum by the operator and hence homogeneous concrete is assured.

ARGO Model’s mantra is ‘Maximum Productivity for Your Investment’: Doing more with less; One extraordinary machine that can do the work of 10 ordinary men with conventional mixing methods that will result in very good savings in terms of Return on Investment.

3. How are the drums of your self-loading concrete mixers designed for better mixing and quicker discharge of the concrete mix?

This innovative machine is capable of Self-loading aggregates, Weigh Batch, mix, transport & deliver concrete within site. The Drum plays a vital role in the quality of the concrete as the mixing process happens inside the drum.

The Dual helix spiral design blades with optimal width provides best-in-class homogenous concrete mix & faster discharge of concrete. Also optimised blade width reduces the friction of the blades with the concrete, thereby reducing the overall maintenance cost.

AJAX ARGO machines are certified by NABL accredited laboratories for complying with IS Standards for Homogenous concrete mix.

The drum lift feature in the ARGO ensures faster discharge of concrete and reduces the cycle time which enhances there by increasing the productivity & life of the machine.

AJAX always understands CUSTOMER requirements and our R&D team works towards the betterment of ROI for the customer during its Product Life cycle.

AJAX ARGO Mixer Drums are equipped with high superior abrasion resistant steel material & helical spirals with end protection that exhibits the highest degree of Wear resistance along with Effective drum mixing delivering industry’s best-in-class homogeneity.

4. Share details of the loading mechanism of the mixers that facilitates weighing, quicker loading with no residual matters left while loading the mix?

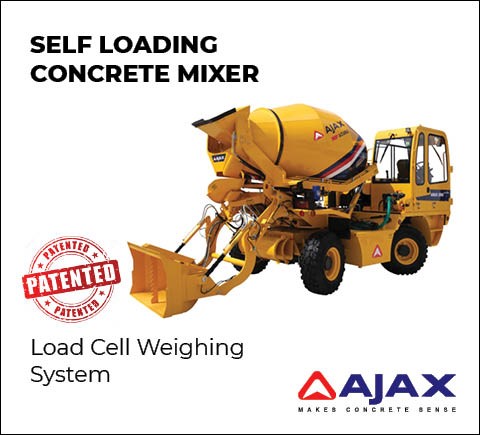

The Multifaceted concrete equipment has a sliding gate bucket which facilitates cement and aggregates to feed into the mixer completely without spillage by the operator. Sensors are placed which measures the load acting on the Pressure Transducers fitted on both sides of the bucket cylinders.

AJAX is always seen as a trend setter in the CE Industry and our Load Cell technology in the SLCM segment will take the concreting to the next level.

AJAX has applied for the Patent in India and has received the Patent in Italy for the Load Cell weighing system for its ARGO SLCM.

AJAX ARGO SLCMs are certified by NABL accredited laboratory as per IS standards for its Load Cell technology machines for “Accuracy of Weigh Batching” which is the core requirement of mega Infrastructure projects such as Bridges, Railways, Flyovers, Buildings to name a few.

5. What are the design attributes of the mixers that make them to work in confined places? Share details of the steering systems in place that facilitates its working in constricted work sites.

This unique product concept of Self-loading Mobile Concrete Mixer is one such prominent testimony in our product range. It is utilized as a merger of Loader, Mobile Batching Plant and Transit Mixer for small to medium volume concrete requirements.

The 4X4 wheel drive provides better control while driving off-road to the operator and the heavy-duty axles ensure better traction on inclined terrains.

ARGO’s have 3 modes of Steering system which allows the machine to work in confined spaces at site.

2 Wheel Steering – For travel on normal roads

4 Wheel Steering – For better tight turning radius at confined space

Crab Steering – For better manoeuvrability & diagonal travel at constrained & tightest space

ARGO comes with a Swivel variant which best benefits the customers at sites where there is a space constraint while placing the concrete. The drum can swivel up to 240 degrees thereby providing customers easy access to discharge concrete.

6. Are the products being sold through your own or distributor channels? What is the nature of product support that is being rendered for the products?

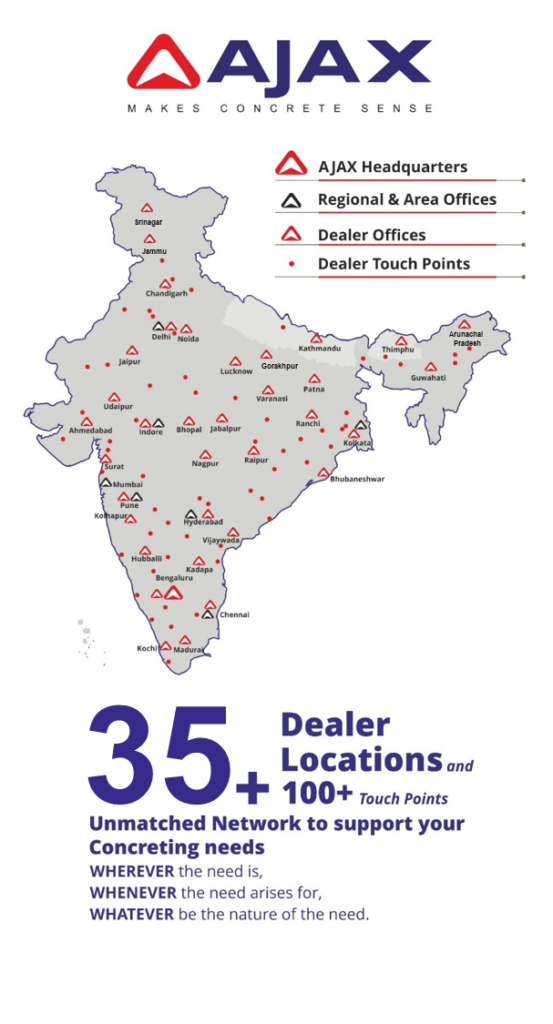

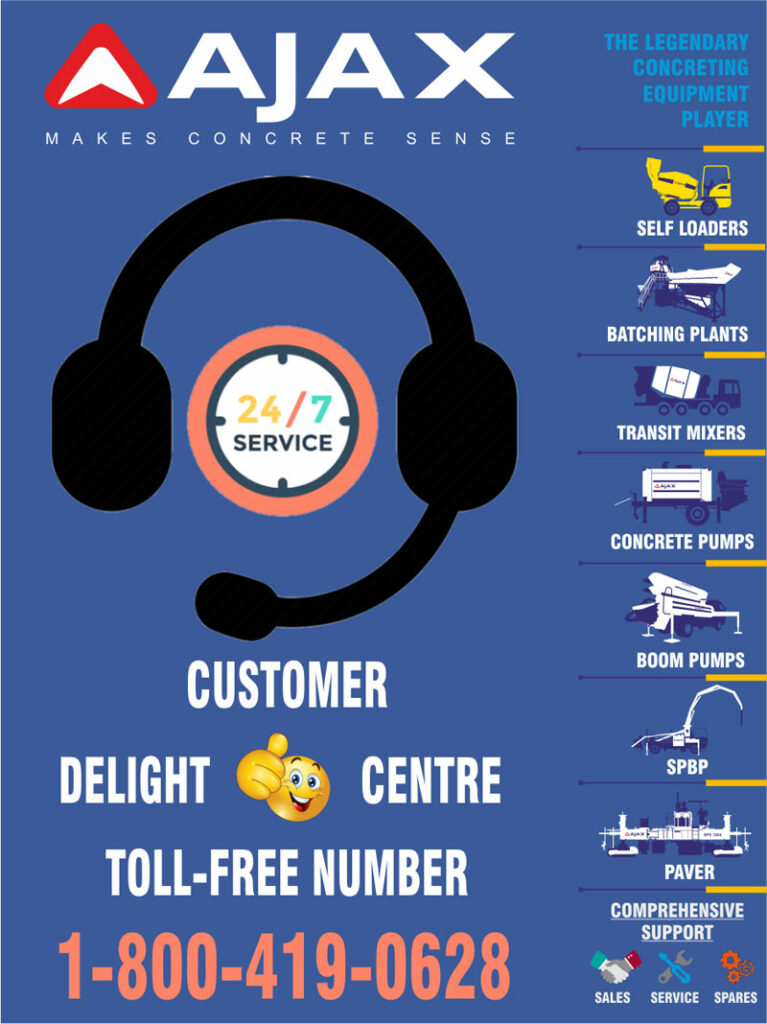

AJAX has a wide Network of Dealers for Product Sales & After Sales Support across the country. Currently 35+ Dealers with 100+ touch points are available to cater Sales & Service for the customer.

AJAX is also serving the International market through 13+ Distributors and has its presence in Asia-pacific, Middle East and North Africa (MENA) regions.

The full-fledged team of skilled engineers of AJAX are trained to handle both preventive and general maintenance of the machine.

AJAX has a robust network of Service Centers across the country. The service centers are fully-equipped facilities to Maintenance, Repair, and Overhaul (MRO) equipment to ensure the best value for money to customers.

AJAX customer care can be reached 24X7 for any queries and requests, thereby enabling round-the-clock support. AJAX offers excellent serviceability options to ensure maximum uptime of the machines thereby enhancing customer satisfaction to a greater level.

7. What promotional initiatives you are taking to push the demand in the areas where its utilization is not fully understood?

AJAX focuses mainly on Customer Meets, Regional Exhibitions, Road shows & Product Demos to target new potential buyers and to penetrate niche markets.

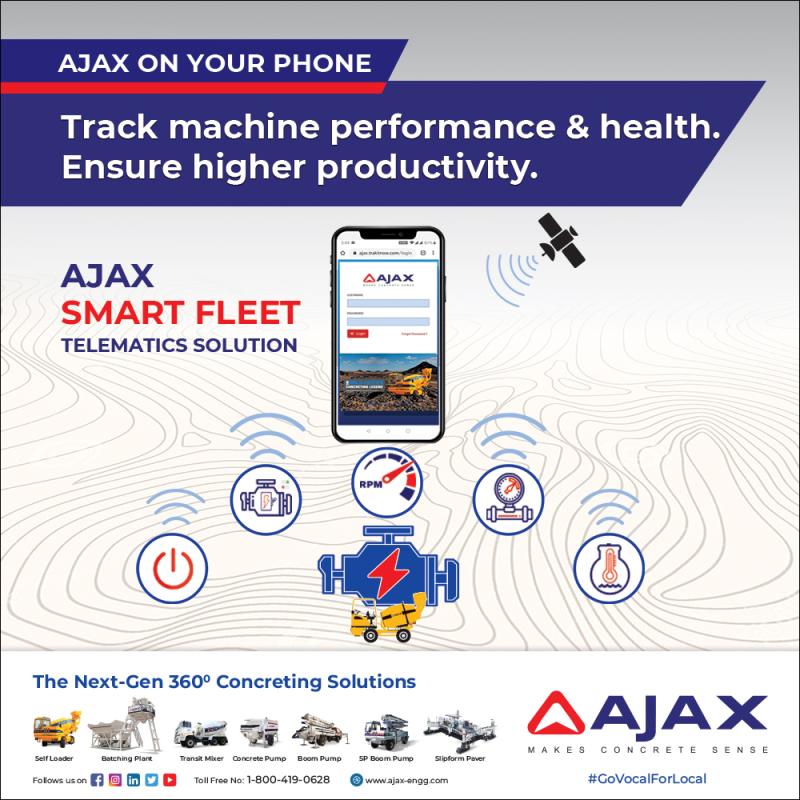

Even during the pandemic peak period, AJAX was in constant touch with its customer base via Digital platforms & virtual conferences. Eventually, AJAX has always strived to emerge as a complete Next-Gen ‘360° concreting solutions provider’ to CE Industry.