In the field of civil engineering, safeguarding the integrity and durability of structures stands as a fundamental objective. However, recent revelations from prominent structural engineers Marsh and Frangopol have brought to light a critical challenge- the rapid deterioration of structures due to inadequate consideration of degradation mechanisms during their construction. This revelation underscores the urgent need to address the vulnerabilities of civil assets and prioritize structural reinforcement measures.

The challenging question client always asks

After structural strengthening, every time the client asks this one particular question to the consultant or the contractor, “What is the life extension of my asset after strengthening”. This question gives goose bumps to the consultant or the contractor. Their answer is usually one of the following: “10 to 20 years” or “Don’t worry I am there” or “We have rehabilitated 300 structures and nothing has happened so far“. Such responses don’t really provide confidence to the asset owner. One of our clients even went on to say that ‘the contractor does not even have confidence in his own work as he does not say a very specific life extension or even the lifetime calculations to support his claim’. Moreover because of this the client does not really know what is the actual life extended of their asset and the time of next repair.

How we overcome this challenge?

We felt that this is a grey area which if we are able to solve we can unlock a new market. To solve this issue, we developed the technology called Target Life Rehabilitation (T.L.R.) design. This technology was developed during the PhD of Dr. Sharvil at IIT Bombay and only provided by our company IRM. In this technology the following steps are involved:

- First perform the Remaining Life Analysis (R.L.A.) of the asset. R.L.A. involves estimation of the deterioration of the load capacity in terms of structural reliability index (or equivalent failure probability) over each passing year, under the expected deterioration, to arrive at the end of useful life. The end of life is the time when the actual probability of failure (actual reliability index) of the structure crosses below the acceptable probability or acceptable target reliability index.

- Ask the client how much life extension they want. Based on R.L.A. the remaining useful life may be sufficient as per their requirement or it may be short of what they expect.

- Based on the difference of remaining useful life and expected life, we provide a strengthening scheme which will precisely satisfy the life required.

What is the USP of T.L.R.

- The advantage of T.L.R. is that we are neither under strengthening nor over strengthening, but optimised strengthening is possible, which saves client’s cost.

- Calculations of life time are provided to the client to demonstrate how we claim that the extended life satisfies the requirement of the client.

- In case when the client has a budget constraint, T.L.R. can quantify how much life can be extended with the available limited budget.

Target Life Rehabilitation (T.L.R.) scheme is devised, wherein customized solutions are implemented to extend the structures lifespan and specific repair life is presented to the client as per their requirement. This approach ensures that the structural strengthening efforts are aligned with the client’s expectations and the structural integrity is maintained for the desired duration. To know more how you can extend the life of your projects for very specific years with minimum cost you can write to us at IRMS365@gmail.com or call +91 9970564547.

Case Study: Reinforced Concrete Chimney

In a crude oil refinery plant, the structures cannot be put out of service frequently. A chimney is one such important component. Disruption of the chimney due its failure causes a hazardous working environment and interruption of the business operation and supply chain.

A reinforced concrete chimney was constructed circa 1983 in the project crude oil refinery. At the time of its investigation during the year 2021-2022 it was already 38 years of age. The client expected that the chimney had degraded due to its long operation and they had doubt and uncertainty about its remaining safe useful life. A shutdown (due to sudden structural failure of the chimney) is economically crippling for the client. The loss due to above mentioned shutdown of the chimney is expected to be Rs 6 Cr per day. In event of such failure, the plant would be shut for more than 60 days, which translates to a loss of more than Rs 360 Cr. Moreover the chimney was constructed with a lot of investment, as such it would be advantageous to extract maximum utility from the chimney without making costly interventions. To this end the client wanted to ensure safety, at the same time wanted to extract any possible utility from the chimney and to extend its use up to year 2034.

The chimney is located in a marine/coastal and industrial environment. The identified deteriorating factors for the reinforced concrete component over the service life of the chimney are chloride & carbonation induced corrosion, global warming, sulphate attack, reduction of concrete strength. All these effects are analysed for the project. To this end, the project began with conducting a Remaining Life Analysis (R.L.A.) of the chimney to extract and evaluate its safe useful life with an acceptable probability or acceptable target reliability index. R.L.A. involves estimation of the deterioration of the load capacity in terms of structural reliability index (or equivalent failure probability) over each passing year, under the expected deterioration, to arrive at the end of useful life. The end of life is the time when the actual probability of failure (actual reliability index) of the structure crosses below the acceptable probability or acceptable target reliability index. The limit state function for collapse against flexure is expressed as

𝐺(𝑧,𝑡)=𝑀𝑟(𝑧,𝑡)−𝑀𝑇

where 𝑀𝑟 is the moment of resistance of the chimney at a section at height 𝑧 and time 𝑡, 𝑀𝑇 total maximum external moment. Similar limit states were created for shear, axial and deflection, which are not included in this article for conciseness. The probability of failure for the limit state is

𝑃𝑓=∫ 𝐹𝑀𝑟(𝜔)×𝑓𝑀𝑇(𝜔)𝑑𝜔

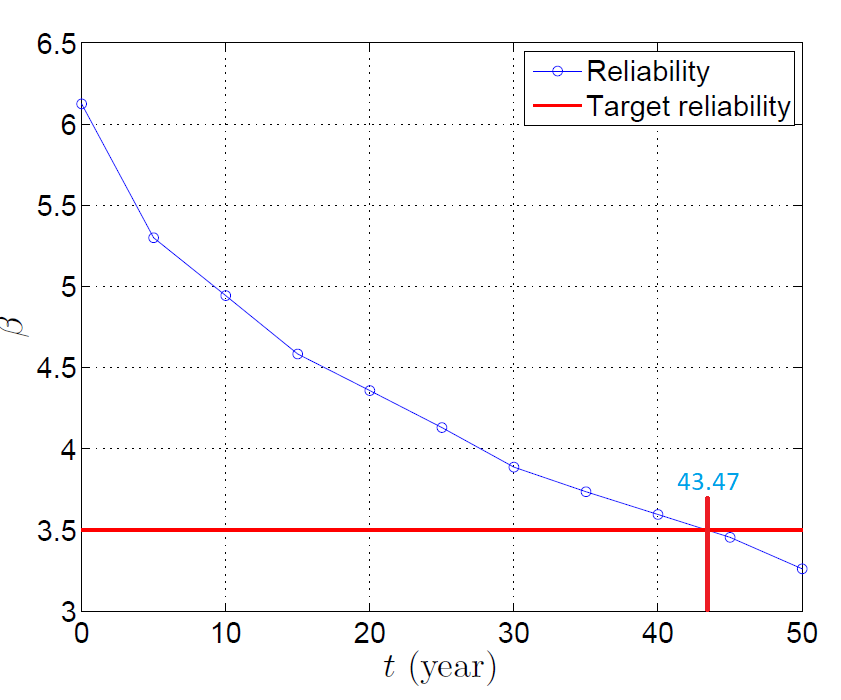

in which 𝐹𝑀𝑟 = the cumulative distribution function (CDF) of moment capacity and 𝑓𝑀𝑇 = the PDF of 𝑀𝑇. The probability is expressed in terms of reliability index (𝛽): 𝑃𝑓= (−𝛽), where 𝛷 is the cumulative distribution function of the standardised Gaussian distribution. Due to the deterioration caused by corrosion and other factors, the reliability index will decrease with time. The end of service life is termed as the time when the actual reliability index of the structure crosses below the acceptable target reliability index. A target reliability of 3.5 is considered. The service-life is terminated if the actual reliability falls below this value. This value is in tune with target reliability provided by EN 1990 and CICIND. Details of data collection, SHM, NDT and data processing are not shown in this article for conciseness. The data collected is used to update the deterioration model of the chimney through Bayesian/machine learning.

Performing the reliability analysis using the Rackwitz-Fiessler method, the reliability profile is obtained, see Fig. 1. Based on this the total useful life of the chimney is evaluated as 43.47 years in flexure. It is seen from Fig. 1, that the failure point in the business cycle is available to the asset owner proactively which will help them in decision making. Similar plots were also obtained for shear, axial and deflection limit states. The present age is 38 years, thus the remaining useful life is 43 – 38 = 5 years.

Figure 1: Flexure reliability profile of the chimney and the forecasted useful life

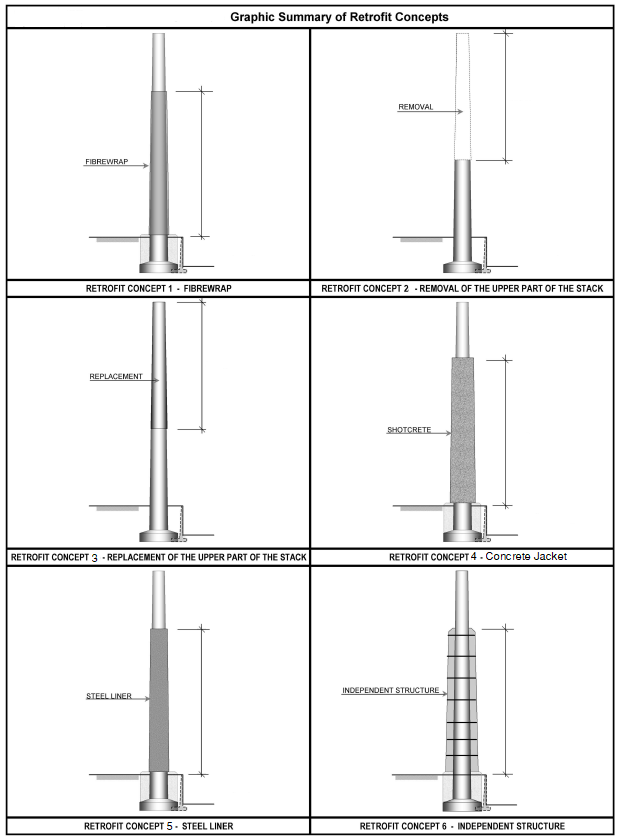

From the vantage point of the year 2021-2022 the chimney still has a remaining useful life of 5 more years. With respect to the year 2034 (up to which the client wants to use the chimney) the chimney requires more life of 12 years. Thus rehabilitation design is required for only; 12 – 5 = 7 years. The loads to be considered for strengthening design are dead load, live load, seismic load, wind loads and corrosion hazard. For the lateral loads like seismic load and wind loads, the hazard modification factors are based on equal probabilities of non-exceedance within different remaining lifespans. The details are lengthy and hence not included here. For corrosion hazard, the concrete and reinforcement properties are designed so as to ensure a corrosion free life. The outcome of T.L.R. is to produce strengthening specifications, longevity calculation of the scheme, specifications of quality indicators and bill of quantity. Six strengthening options were explored, see Fig 2:

- FRP wrapping

- Reducing height of chimney

- Replace reduced height with steel shell

- Concrete jacketing

- Steel liner

- Stiffening with steel plates

Figure 2: Graphical Summary of Retrofit Options

Out of the above, options 2, 3 were discarded. The rest of the schemes were designed using Target Life Rehabilitation (T.L.R.) to achieve a target life of 7 years. Now it remains to decide which option to be used. The decision was based on the cost comparison. Since all options were providing a life of precisely 7 years, it was decided that the final scheme for implementation can be decided based on minimum cost. The following table provides cost comparisons for the options. The option 4 was selected as it provided the least cost.

| Options | 1 | 4 | 5 | 6 |

| Cost ratio w.r.t. option 4 | 1.05 | 1.00 | 1.46 | 1.07 |

Tangible benefits to the client

- Cost of replacement and reconstruction was 2.75 times the strengthening option 4, leading to a saving of 1.75 times.

- Replacement of stack would require a downtime of 60 days, while T.L.R. was performed on a running unit, saving 35 days of unit operations (25 days were planned shutdown)

- Potential saving of Rs 210 Cr (= 35 days x Rs 6 Cr per day)

Conclusion

Industries involved in the business of energy, refining, mining, etc. cannot have an interruption of their operations. Any interruption leads to losses running in billions of rupees. Conventional structural assessment and strengthening is unable to forecast the performance of the structure and thus keeps the asset owner in the dark. This increases the uncertainty and amplifies the risk for such business, which can potentially lead to loss of their revenue. This paper provides an engineered strategy for the asset owners for proactively evaluating the remaining life of their assets using R.L.A., thereby eliminating surprises of sudden distress and preventing collapse; and technology to extend life of their assets for a very specific years post strengthening via T.L.R. saving billions of rupees and peace of mind. The cost of not adopting R.L.A. + T.L.R. for the asset owner is i) owning the risk responsibility, ii) incurring unnecessary or excessive repairs and iii) no peace of mind.

About Authors

Dr. Sharvil Alex Faroz is the founder of IRM, the company has roots in IIT Bombay. He holds PhD in structural engineering from IIT Bombay and affiliated to esteemed institutions such as IEI, IIBE, ISSE, ICE and SRESA. During his PhD, Dr. Sharvil deliberated with various civil asset owners and understood their challenges specifically regarding all the life cycle issues of such assets which they face. Through this insight, his PhD focused on creating an applicable technology for evaluating the Remaining Useful Life of civil structures which help clients with decision making on Longevity and Rehabilitation. The company is based on this technology. IRM is helping clients to massively reduce the Risks and minimise the Operation & Maintenance cost of their civil structures and extending their service life. These assets include commercial buildings, bridges, refinery chimneys and more. The company is also actively involved in R&D to make new technologies available to clients at minimum cost. The company has grown 7X since its inception.

Saurabh Pawade is a structural engineer at Infrastructure Risk Management (IRM). With a Bachelor’s degree in Civil Engineering and ongoing post-graduation in Structural Engineering. Proficient in software like Staad Pro, Etabs, and AutoCAD, he combines technical prowess with effective communication skills, seeking challenging opportunities to further his career and contribute to organizational growth.