With the popularity of new energy vehicles (EVs)and renewable energy, Zambia’s long-neglected copper mines have once again attracted attention.

Zambia possesses one of the world’s highest-grade deposits of copper and is ranked the seventh largest copper producer in the world.

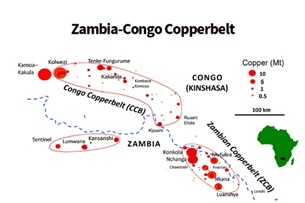

Copper mine distribution in Zambia

Zambia has proven copper reserves of 1.2 billion tons, with an average grade of 2.5%. The copper ores are rich in reserves and are shallow and easy to mine.

Most of the copper deposits in Zambia are mostly concentrated on the copper belt, the Zambia-Congo copper belt. This copper belt is located in northern Zambia. The main industry in the area is copper mining.

The Zambia-Congo Copperbelt is the world’s largest sedimentary copper deposit. It is 220 kilometers long and 65 kilometers wide, and contains 25% of the world’s copper reserves.

The copper belt is distributed in parallel along the Kafue River.On the west side, there are the Lumwana copper deposit (one of the world’s largest undeveloped copper deposits), Kansanshi Copper Mine, Konkola Copper Mine, Nchanga Copper Mine (the world’s fourth-largest open-pit copper mine), etc.On the east side, there are Bwana Mkubwa and Mufulira copper mines near Ndola.

Copper ore price

Copper prices have continued to surge as the global economic recovery strengthens, hitting new annual highs. Demand is also bullish, helped by government stimulus spending on infrastructure, especially in China, the world’s largest copper importer.

In addition, the world is turning to clean energy solutions. The promotion of Electric vehicles and green energy relies heavily on copper ores. It is forested that copper consumption will grow at an annual rate of about 2% in the next 10 years.

Copper ore crushing and screening process

The newly mined copper ore needs to be crushedinto a certain particle size to meet the feeding size requirements of subsequent grinding operations.

The supplier of ore processing equipment Ftmmachinery divides the copper ore crushing process into three parts: coarse crushing and screening, medium crushing, and fine crushing.

1. Coarse crushing and screening

Large blocks of copper ore are fed into a jaw crusher or mobile crushing station by a vibrating feeder for coarse crushing.

Jaw Crusher

Ftmmachinery Jaw Crusher is an ideal crusher for copper ore coarse crushing.

1. The deep crushing chamber can be used for crushing the copper mine without a dead zone, thus increasing the crushing efficiency of the copper mine.

2. Finite element analysis (FEA) technology can effectively improve the crushing strength of the crusher and expand the crushing range of copper ore.

3. The discharging size can be controlled by adjusting the wedge.

4. The floor area of the equipment is effectively reduced due to the reasonable design. It is convenient for customers to operate and maintain in production.

Vibrating screen

The crushed copper ore is screened by a vibrating screen. The qualified copper ore is discharged through a belt conveyor, while the unqualified ore returns for crushing again.

“Ftmmachinery Vibrating Screen is small and light, so it is easy to install. It not only has a large screening capacity but also consumes less energy.” says Steven,Ftmmachinery’s product manager.

2. Medium crushing

After coarse crushing and screening, the copper ore is sent to a single-cylinder hydraulic cone crusher for medium crushing.

Single cylinder hydraulic cone crusher

1. In the case of iron-passing, the cone crusher can hydraulically lift the top and automatically discharge the material.

2. All parts can be disassembled and maintained from the top or side, without disassembling the frame and fastening bolts.

3. The crushed product is in the shape of a cube with a low content of elongated and flaky particles.

4. The output size can be adjusted by hydraulic pressure, which only needs to be controlled by a buttonwith high adjustment controllability.

5.When the material with super-crushing pressureentersthe crushing chamber, the pressure regulating system will automatically start to perform pressure relief protection, and the discharge port will be automatically enlarged to protect the equipment.

3. Fine crushing

The copper ore after medium crushing enters a multi-cylinder hydraulic cone crusher for fine crushing. Finally, copper ore below 12 mm can be obtained.

Multi-cylinder hydraulic cone crusher

1. The crusher adopts a high-strength integral casting frame, with long service life and high reliability.

2. The discharge port can be adjusted by a hydraulic motor, which can realize the remote, accurate and continuous adjustment of the discharge opening size.

3.The high-efficiency lamination crushing improves the crushing efficiency and reduces the wear of vulnerable parts.

4. No filler is required for the installation of the lining board, so its replacement is low faster and cost-saving.

5. The equipment adopts multiple protections of labyrinth type and spherical floating seal, making the seal more reliable and dustproof.

6. The transmission system adopts spiral bevel gear transmission, which has a strong bearing capacity, stable transmission and low noise.

7. Adopt automatic PLC intelligent control and integrated hydraulic lubrication system.

Conclusion

Zambian copper production is expected to increase in the futureand Zambia’s major miners are also optimistic about the copper mine prospects. Ftmmachinery crushing and screening machines are specially designed for copper crushing