Arch bridge as it consists of horizontal thrust developed is restrained by the abutments provided at each end of the bridge. It is curve-shaped or arch-shaped in which the flexuous support spans the gap and serves as a support for the loads on top of the opening. This definition omits an outline of what variety of structural component, an instant, and axial force component, makes up the arch.

Its main structure is composed of arches or reinforced arches. Arch bridges are very economical and advantageous if the horizontal reaction force caused by the loading of vertical loads is effectively applied and if they are properly designed to reduce sectional forces of members. Arch bridges are used for long-span bridges after suspension and cable-stayed bridges.

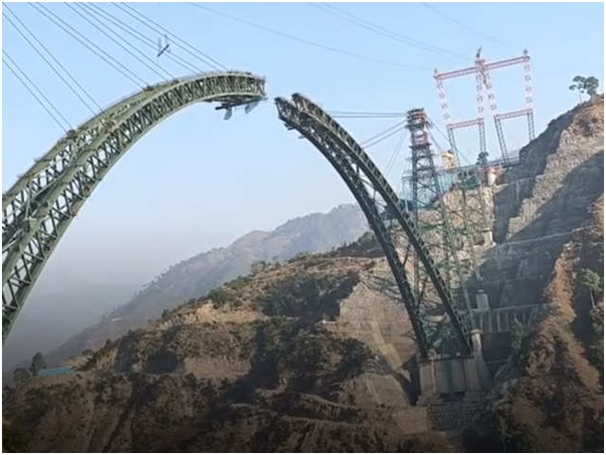

The bridge is shaped as an upward convex curved arch to sustain the vertical loads. A simple arch bridge works by transferring its weight and other loads partially into a horizontal thrust restrained by the strong abutments at either side. The arch rib needs to carry bending moment, shear force, and axial force in real service conditions.

The main components of arch bridges;

- Arch rib- The arch rib is the main structural member of the arch and is responsible for carrying the different loads generated in the structure. The arch ribs are commonly built using reinforced concrete or steel, but new innovative materials have been used for the arch ribs, including concrete-filled steel tubular, high-performance concrete, steel concrete composites, etc. The arch rib can be built as a truss, a box girder, a plate girder, or as a hollow section, depending on its usage.

- Abutments/Supports- The abutments/supports are one of the most important components of arch bridges because most of the loads carried by the arch rib are transmitted into the abutments. Therefore, the abutments must be heavy and large enough to carry the horizontal thrust from the arch. Reinforced concrete and steel are common materials used for the abutments, but new materials like cellular reinforced concrete and mass concrete are also used

- Hangers and Spandrels- The deck can be supported by spandrels on top of the arch rib suspended by vertical hangers. For deck arch bridges, solid spandrel walls can be placed on top of the arch rib to support the bridge deck. The fill on the walls are mostly made out of masonry or concrete. However, modern bridges use a different approach by adding vertical columns made out of steel or concrete that directly support the deck of the bridge.For through arch bridges, the deck of the bridge is suspended by hangers, which are loaded in tension.

Different types of arch bridge

Deck Arch Bridge

In this type of bridge, the deck that has a structure that directly supports the traffic loads is found on top of the crown of the arch. This type of bridge comprises an arch where the deck is completely above the arch. The area between the arch and the deck is known as the spandrel. If the spandrel is solid, usually the case in a masonry or stone arch bridge, the bridge is called a closed-spandrel deck arch bridge. If the deck is supported by a number of vertical columns rising from the arch, the bridge is known as an open-spandrel deck arch bridge.

Through Arch Bridge

In this bridge type, the upper deck is found at the spring line of the arch. It is also known as the half-through arch bridge. For this type of arch bridge reinforced concrete or steel material is used. It has an arch whose base is at or below the deck, but whose top rises above it, so the deck passes through the arch. The central part of the deck is supported by the arch via suspension cables or tie bars, as with a tied-arch bridge. The ends of the bridge may be supported from below, as with a deck arch bridge. Any part supported from arch below may have spandrels that are closed or open.

Moment Tied Arch Bridge

This type of bridge includes the floor beams connected to a tie to form an affiliation between the arch and the tie.

Pinned‐Pinned Concrete Arch Bridge

This type of bridge consists of roller supports which permit the linear motion at the side of rotation. It can resist and permit rotation for even tiny low moments. The friction between the two connecting members can also resist some moments. Roller support permits linear motion at the side of rotation.

Bowstring Arch Bridge

This type of bridge essentially consists of tension ties between two opposite ends of the arch. The tension ties are responsible for carrying the axial loads and the unsymmetrical flexure carried by the arch.

Corbel arch Bridge

These bridges are created by parturition sequential layers of masonry or stone with every having with success larger cantilevers. It is a masonry, or stone, bridge where each successively higher course cantilevers slightly more than the previous course. The corbel arch does not produce thrust, or outward pressure at the bottom of the arch, and is not considered a true arch. It is more stable than a true arch because it does not have this thrust. The disadvantage is that this type of arch is not suitable for large spans.

Aqueducts and canal viaducts

These series of arched structures were however not solely in one layer just like the normal bridge, with many layers that might reach spectacular heights.

Conclusion

Arch bridge’s biggest advantage is that it can be fixed, hinged or tied at the supports. The introduction of those new materials permits arch bridges to be longer with lower spans. Most modern arch bridges are made from reinforced concrete. This type of bridge is suitable where a temporary centering may be erected to support the forms, reinforcing steel, and uncured concrete. When the concrete is sufficiently set the forms and falseworks are then removed. It is also possible to construct a reinforced concrete arch from precast concrete, where the arch is built in two halves which are then leaned against each other.