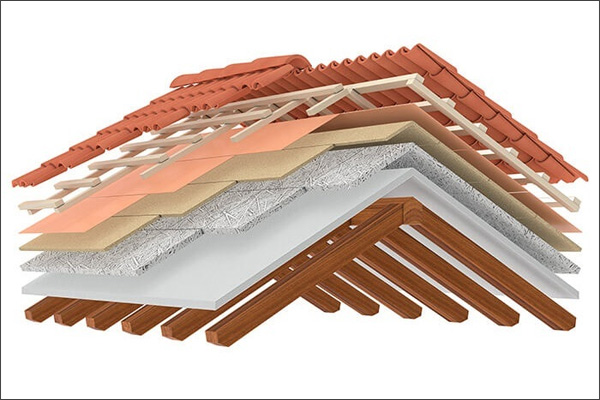

Roof insulation method to prevent heat penetration from the outside environment to inside of the building. The method provides temperature stability and prevents unwanted noise penetration. The importance of thermal insulation has increased recently mainly due to changing insulation standards worldwide, which put higher demands on the thermal resistance of building structures to reduce energy loss for heating or cooling. Insulation materials should have not only high thermal characteristics but also sufficient mechanical properties to be able to withstand loads. Wise insulation choices result in successful roof systems that perform over the long term, while poor choices can be detrimental to roof performance.

Advantages of Roof Insulation

Reducing energy costs is one of the top reasons for reassessing the insulation in buildings. Whether building a new home, or renovating your current one, the selection of your insulation system warrants some serious attention. Adding insulation can offer you a lifetime of energy savings while improving the energy efficiency and comfort to your home. It provides several advantages.

- It provides high thermal performance

- Gives good mechanical strength

- It is resistant to solar radiation

- Act as a barrier for air, wind, and moisture

- Prevent vapor transmission by applying exterior and interior insulation

- Lessens your carbon footprint

- Prevents the growth of molds

Types of Roof Insulation

Blanket Insulation or Matting Insulation – comes in foil-backed rolls or rafters, and are held in place using timber battens between the rafters or joists. This is made of glass wool or mineral but sometimes these are also made from plastic fibers and natural fibers.

Foam Boards Insulation – a great alternative to the very common fiberglass batt insulation that is in most of our homes. It has a higher R-Value per inch of thickness, it’s resistant to moisture and is easy to work with. Common foam boards are made of polystyrene, polyisocyanurate, and polyurethane.

Radiant Barrier – it reflects heat radiation, preventing transfer from one side of the barrier to another due to a reflective, low emittance surface. The radiant barrier may be one or two sided. One sided radiant barrier may be attached to insulating materials, such as polyisocyanurate, rigid foam, bubble insulation, or oriented strand board.

Blown-in Insulation – it fills between existing wall studs and ceiling joists quickly and easily. Blown-in ican also seal small gaps and spaces as it settles, filling these sneaky spots where cold air would otherwise come in.

Sprayed-Foam and Foamed-In-Place Insulation – Liquid foam insulation method in which materials can be sprayed, foamed-in-place, injected, or poured. Foam-in-place insulation can be blown into walls, on attic surfaces, or under floors to insulate and reduce air leakage. Some installations can yield a higher R-value than traditional batt insulation for the same thickness and can fill even the smallest cavities, creating an effective air barrier.

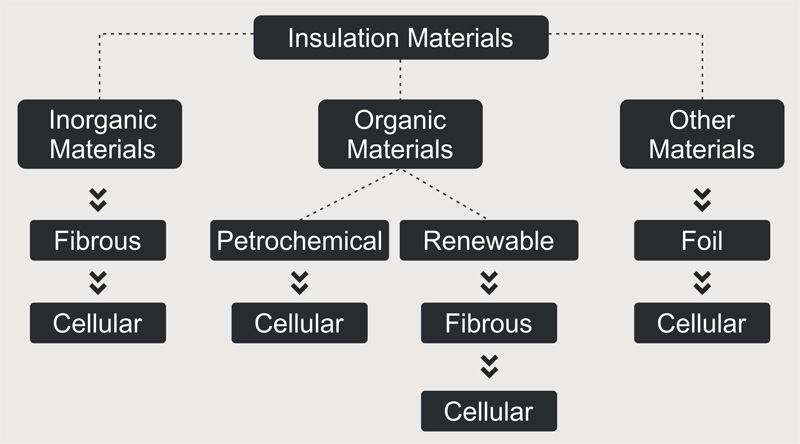

Types of roof insulation materials

There are different types of materials which are used for different types of roof insulation as per project requirements.

There are different types of roof insulation materials used as per project requirements, each of them is explained below.

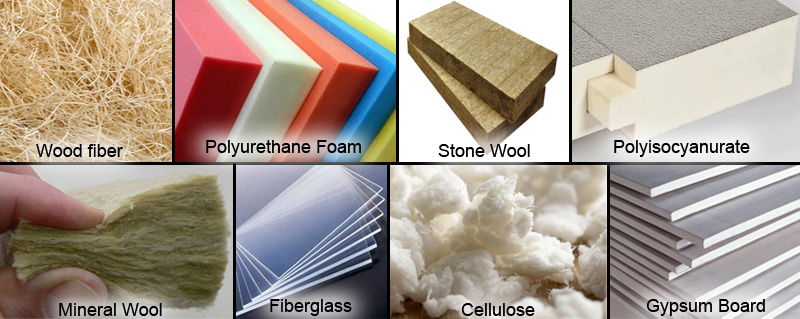

Wood fiber – an organic insulation board composed of wood, cane, or vegetable fibers mixed with fillers and binders. The insulation can be asphalt impregnated or asphalt coated to enhance moisture resistance.

Polyurethane Foam – a thermal insulation board produced in a chemical process from rigid polyurethane (PU) foam combined with an isocyanurate catalyst. This is a very universal and efficient solution for all kinds of exposed roofs.

Mineral Wool – manufactured from recycled glass or rock wool which is a type of insulation made from basalt. Mineral wool can be purchased in batts or as a loose material.

Stone Wool – a type of mineral wool insulation produced from basalt stone fibers. It is one of the most common solutions for exposed mechanically fastened roofs, especially where very high fire resistance is required.

Polyisocyanurate – a closed-cell foam plastic insulating core sandwiched between organic or inorganic felt facers, glass-fiber mat facers, or glass-fiber-reinforced aluminum foil facers.

Fiberglass – consists of extremely fine glass fibers. It is commonly used in two different types of insulation, which are batts and rolls, and loose-fill. It is also available as rigid boards and duct insulation.

Cellulose – an eco-friendly insulation material composed of 75-85% recycled paper fiber, usually post-consumer waste newsprint. The other 15% is a fire retardant such as boric acid or ammonium sulphate. Because of the compactness of the material, cellulose contains next to no oxygen within it.

Spray polyurethane foam – made by mixing and reacting chemicals to create foam. The mixing and reacting materials react very quickly, expanding on contact to create foam that insulates, air seals and provides a moisture barrier.

Cellular glass – composed of crushed glass combined with a foaming agent. The components are mixed, placed in a mold, and heated, which melts the glass and decomposes the foaming agent.

Gypsum board – a non-structural, non-combustible, water-resistant, treated gypsum core panel. The board is available with a proprietary, non-asphaltic coating on one side to enhance roof-membrane adhesion.

Polystyrene – a transparent thermoplastic material is commonly used to make foam board or beadboard insulation, concrete block insulation, and a type of loose-fill insulation consisting of small beads of polystyrene.

Polyisocyanurate – a thermosetting type of plastic, closed-cell foam that contains a low-conductivity, hydrochlorofluorocarbon-free gas in its cells. Polyisocyanurate insulation is available as a liquid, sprayed foam, and rigid foam board. It can also be made into laminated insulation panels with a variety of facings.

Perlite – composed of inorganic, expanded siliceous volcanic glass, perlite combined with organic fibers and binders. The top surface of the insulation board features an asphalt coating or a proprietary coating formulated to limit adhesive.

Glass rock and mineral wool – made primarily using glass or rock that has been melted down at temperatures well over 1,000°C and spun into fine strands of wool. A binding agent is also added to help hold the strands together.

Natural Fiber – few natural fibers including cotton, sheep’s wool, straw, and hemp–are used as insulation materials.

Conclusion

While some insulation products lend themselves better to the do-it-yourself, it is generally recommended that a professional or certified insulation contractor perform the insulation work. As the consumer, however, you need to be informed about the types of insulation material available as discussed above.