In structural engineering, a prefabricated sheet is designed by a manufacturer using a predetermined inventory of raw materials and manufacturing methods that can efficiently satisfy a wide range of structural and aesthetic design requirements. Using prefabricated sheets on your structures will allow you to realize profits sooner. Prefabricated increases safety for individuals who are on site. Panels are built in our factory, trained install teams are deployed with the essential skills to get the job done. Taking trades and equipment offsite and being able to assemble the components in a weather controlled zone are ways to make the job site safer. In order to accurately design a pre-engineered building, engineers consider the clear span between bearing points, bay spacing, roof slope, live loads, dead loads, collateral loads, wind uplift, deflection criteria, internal crane system and maximum practical size and weight of fabricated members.

Advantages of prefabricated sheets

The design stage is one of the most important aspects because a well-planned and well-designed project can produce tremendous cost saving benefits. Since the panels are built in advance in factory, cost savings can be found in a reduction of materials and labour on site as well as a decreased project schedule. Its advantages are-

- Reduce project schedules dramatically through the rapid installation

- Installation process will allow you to have a reduction of labour on site

- The prefabrication method takes far lesser time

- Easily dismantled and relocated

- Several quality tests are performed before it rollout

- Significantly reduces the demand for raw materials, minimizes expended energy and decreases time overall

- Occurs in a controlled manufacturing environment and follows specified standards

- High in quality, durable and economical.

- Lighter in weight, easy to move and highly Insulated

Different types of prefabricated sheets

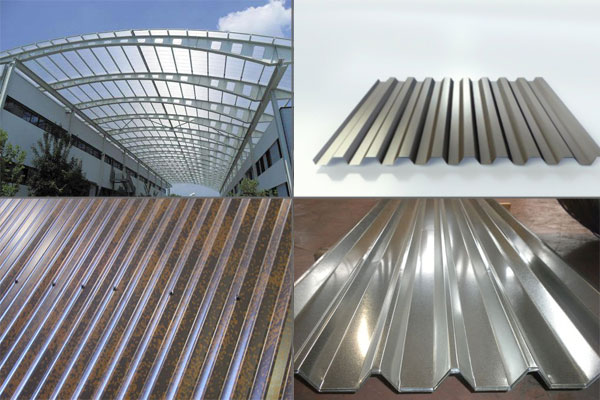

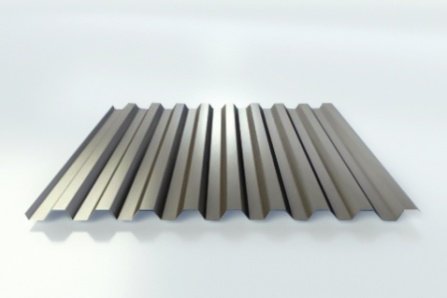

Corrugated sheets

Corrugated is highly durable and it is because of its shape. These sheets require the support strips to stabilize the material since the screws for fastening do go through the peak of the ribs. The curvature of the ribs and valleys prevents the screws from sealing adequately in the valleys. Because of the special corrugated shape, flimsy and lightweight metals like aluminum can also be equipped to undergo decades of weather beating.

Polycarbonate sheets

Polycarbonate sheets are available in a variety of qualities and thicknesses. They are much lighter in weight, yet durable, and resistant to breakage and cracks. They can be easily handled and can be fixed with the help of screws and support rods, or can be easily welded. Also, these sheets can be easily cut with the help of sharp-edged scissors and circular saws without the need for any additional tools and machinery. Polycarbonate roofing sheets being so strong and flexible helps the structures it is used to be more creatively designed. One of the most beneficial features of polycarbonate is that it lets in maximum sunlight while keeping out the harmful UV radiation.

Corrugated polycarbonate sheets

Corrugated polycarbonate sheets are available in a range of choices for light transmission and possess fire-resistant properties. These roofing sheets are manufactured with precise specifications to find an apt use in industrial roof illumination and daylight cladding. The use of corrugated polycarbonate roofing sheets is greatly beneficial in enhancing daylight harvesting.

Metal sheets

Metal sheets are a popular option as they come with great insulating properties. They are made of Zinc, Aluminium, Copper and Tin. Metal roofing provides many advantages, including the ability to withstand nearly any type of weather condition. Metal roofing comes in many different colors and finishes including the look of natural cedar shakes or stone. It has greater fire resistance and the ability to withstand a storm without damage.

Cladding metal sheets

Cladding metal sheet acts as a covering building material with a ‘protective layer’ to provide several practical and aesthetic advantages. They are composed of aluminum or steel. These types of roofing sheets shield the internal building materials from the harsh elements and increase the mechanical stability of the structure.

Plastic sheets

Plastic sheets are light in weight, making them easy to carry, transport, and install. They are durable and cost-effective as compared to metal sheets. These sheets are easy to clean and are resistant to chemicals and corrosion.

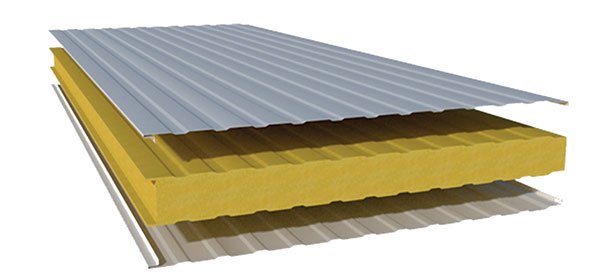

Sandwich panels sheets

Sandwich panels sheets can be called composite panels or structural insulating panels (SIP). It consists of two layers of a rigid material bonded on either side of a lightweight core. The three components function as a composite together; that is, the combination of the component characteristics results in better performance than would be possible if they were working individually.

Conclusion

The foremost characteristic of prefabricated sheet is that each component can be manufactured separately and then transported to the site of construction, where it is fabricated together to form a structure. This flexibility of assembling and disassembling different parts of the structure provides space for innumerable opportunities.

Image Source: isopan.com, arunplasto.in, tuflite.com, georgantas.gr, sbed.cardiff.ac.uk, gutta.com, exportersindia.com