Mini excavators are tracked or wheeled vehicles with an approximate operating weight from 0.7 to 8.5 tonnes. It generally includes a standard backfill blade and features an independent boom swing. In recent years, hydraulic excavator capabilities have expanded far beyond excavation tasks. With the advent of hydraulic-powered attachments such as a tilt rotator, a breaker, a grapple, or an auger, the excavator is frequently used in many applications other than excavation.

Advantages and attachments of a mini excavators

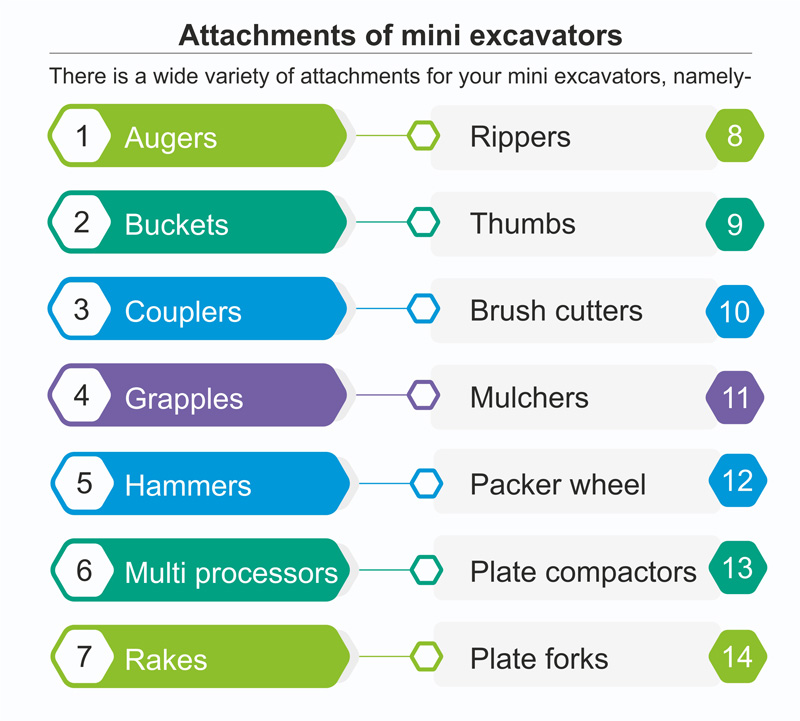

One of the primary reasons why many contractors and builders prefer hiring mini excavators as opposed to full-sized ones is because these machines can easily get into small space. These smaller excavators for hire can be transported easily and efficiently. It has become very popular in the construction, industry, housing and infrastructure sectors. This is due to their practicality, high performance, reliability, and excellent business values. One of the major draws of mini excavators is that you can use them for a slew of different tasks. The sheer number of possible attachments and the light frame are what make the mini excavator such a versatile machine.

Technological development in mini-excavators models

Full-rotation mini excavators

The newest mini excavator models feature a full-rotation (FR) design. This enables to dig offset to the right or left without needing to reposition the machine, and it allows more of the counterweight to remain in line with the center of the machine for greater stability. An available cab provides an automotive-styled interior equipped with optional air conditioner, defrost, windshield wiper and washer, skylight with sunshade, Bluetooth radio, and a high back suspension seat with headrest.

Ultra short tail swing excavators

Mini excavators are now designed to perform a wide range of functions with ease. Its sculpted form and wide open covers look aesthetic and enhance serviceability. The machine’s performance hydraulic pilot levers enhance the operational efficiency of the machine. This machine is extremely versatile and ably meets the needs of different customer sites.

Mini excavators with an adjustable boom

Newer hybrid model mini excavators are ideal for use in tight spaces and applications such as general and residential construction, landscaping, and utility work. These mini excavators provide parallel, unobstructed operation near obstacles, tree lines, and foundations thanks to their zero, short-tail, or conventional swing design and independent center swing boom that can be offset left or right within an operating range. The machine features an adjustable boom with the ability to offset left or right to work closer to buildings and obstacles.

Mini excavators with the main boom with top-mounted lift ram

Modern models are now designed specifically with the rental and contractor segments in mind. Toughness is personified by the full-width solid cast 173kg counterweight that provides maximum protection for the rear of the machine. The heavy-duty strong H frame undercarriage provides rigid support and an open design allowing spoil to fall readily through to the ground preventing excessive componentry wear and minimal cleaning time. For ultimate rigidity, the extending (from 980-1,330mm) undercarriage beams are constructed from a 25mm solid steel plate. The high tensile four-plate boom and dipper design provide maximum strength and durability. The 1,800mm main boom with top-mounted lift ram provides maximum protection for the hydraulic cylinder components.

Mini excavators with no rear overhang

New models are coming for e 4- or 5-metric ton class. Thee comes with the Z stands for zero tail, with no rear overhang, which ranges from 800-kilogram to 15-metric tonne excavators, to include two powerful machines that are suitable for a wide variety of applications. High performance, compact dimensions, comfortable operation: these are the demands being put on excavators of this class. The powerful drive allows customers to deploy the machines for demanding tasks as well. The wide-opening covers make access to all service points easier, which results in less downtime and thus cost savings.

Mini excavators with 3.5 tonnes lifting capacity

The new models with 3.5t mini excavators provide high levels of productivity. The short tail swing makes this machine ideal for working in confined spaces. The bucket forces and digging depth are among the best on the market for improved productivity. The hydraulic offset of the boom makes it possible to work alongside a wall. User-friendly fingertip controls enable the most delicate work to be done quickly and precisely. A quality machine providing high levels of operator comfort and all-round visibility.

Fully electric mini excavators

The new fully electric mini excavator can put in a typical full day’s shift for a mini excavator on a single charge. The new fully electric mini excavator includes three or four lithium-ion battery packs providing a 15-20kWh storage capacity, a load-sensing hydraulic system delivering powerful digging performance, a sophisticated battery management system ensuring full-shift availability. A convenient onboard charger with capability for both 110V (12-hour recharge) and 230V (8-hour charge) comes as standard. The fast charge option, allowing a full charge in under 2 hours, is also available.

1-tonne electric mini-excavators

Combining zero emissions, low noise, and a width of just 71 cm, the new E10e battery-powered, zero tail swing (ZTS) mini-excavator can easily pass through standard doors and in and out of lifts, making it ideal for indoor applications such as demolition and basement construction. When doing indoor work such as demolition and digging out basements, there are very specific requirements. Until now, there has been no standard OEM solution for such work – many jobs had to be worked on manually with less effective tools or with aftermarket conversions providing third party machine adjustments.

Mini excavators with a remote monitoring system

Mini excavators with Remote monitoring system aids owners to check the operational status of their machine at any time and to prevent theft. Other information is also displayed in the system, including engine performance, heat, and other irregularities. An alert will be sent to the user when it is time for maintenance, making it easy for users to care for their equipment and keep track of maintenance schedules, especially those operating several excavators.

Conclusion

Mini excavators are gaining ground in many emerging markets. It will certainly witness growth in the long run but progress in this industry is directly related to demand from the construction industry which is further bifurcated into two i.e. real estate and infrastructure industries. And, with smart cities in the pipeline, increasing infrastructural investment in road construction and housing projects will ensure the growth of the mini excavator market.

Image Source: khl.com, komatsu.eu, cat.com, jcbcea.com.au, kobelco-usa.com, deere.com, volvoce.com,