IBMS (Indian Bridge Management System) was initiated by the Ministry of Road, Transport and Highways (MORTH) in 2015 initially for a 3-year time frame. By December 2019, all the field consultants’ contracts were closed on as is where is basis and no further steps have been taken to continue with this initiative. The work is incomplete and needs further action.

India does not have any legislation to force safety of the bridges and so it is left to the government of the day to push for sustainability of the Bridge Management Programs which is an effective tool to ensure safety of the bridges.

During the period from June 2015 till October 2019, when the field consultants were working on the field, various shortcomings of the project were noticed

- Inadequate training to the inventory and inspection engineers.

- The client’s official did not have p codes to rely on for commissioning the tests to be carried out on bridges to confirm or reject the type of distress.

- There was no legislation in place in India which mandated the need for inspection of bridges leading to rehabilitation intervention.

- There are no codes and guidelines for activities within IBMS.

This last article in the series on IBMS deals with the need to establish a formal institution for bridge management in India to sustain and derive benefits from the development of IBMS.

LEARNING FROM IMPLEMENTATION OF IBMS

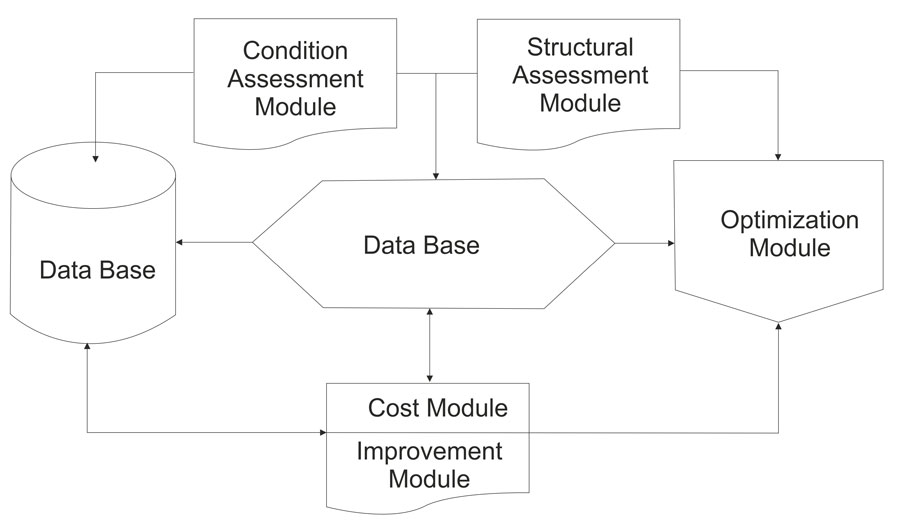

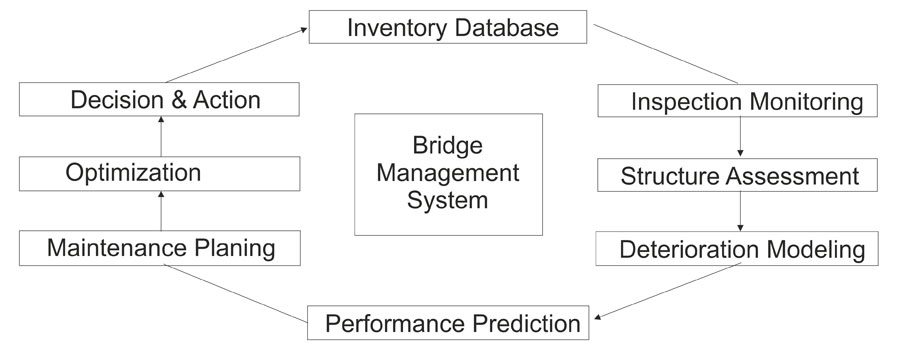

From June till October 2015, development of IBMS was underway. During this period, the concept document was discussed within the Ministry and bilaterally with our development team. The basic structure of IBMS was evolved by us and put forward to the Ministry for acceptance. Series of meetings took place and based on the deliberations and the discussions; the software team was mandated to implement the modification essential in the software. The procedure for implementing inventory and inspection modules were discussed and the process to start testing was left to a later date. Repair and rehabilitation intervention were to be undertaken by respective organizations responsible for maintenance of the bridges.

During implementation of inventory and inspection modules the need to have trained manpower was seriously felt. Basic training for operation of software was imparted to over 300 field engineers. This was a 6 to 8 hours training in various procedures and steps essential to move seamlessly within the IBMS software during field operations. Training did not cover the basic or intricate engineering skills required by bridge inspection teams. This resulted in multiple shortcomings in data collection and data authenticity. Many times, the submitted data did not match with photographic submission or there would be a clash of information within the database.

Post completion of one cycle of inventory and subsequent inspection cycle, a list of bridges was identified for testing. The officials within the department were not comfortable initiating the testing as the previous experience of testing and the conclusions drawn from this exercise was not encouraging. More reliability was accorded to information submitted by the field officers of the various departments responsible for the bridge maintenance. This created a decision paralysis and, in the process, testing was sidelined. Second cycle of inspection was started and subsequently a third cycle of inventory and inspection was undertaken. The entire process of testing was totally sidelined and only inventory and inspection were repeated.

The maintenance authorities did not have sufficient budgetary support to undertake large volumes of distress management. In place specifications were for cosmetic rectification of visible symptoms rather than to rectify and address the cause of defects. This led to allowing the bridge to deteriorate further, till a time when it can be declared critical and recommended for replacement. During 5 years of implementation of IBMS, no major rehabilitation program was initiated. Absence of compulsion arising from legislations which mandate timeline for undertaking remedial intervention resulted in the continued decision paralysis.

During the entire process of inventory and inspection module implementation it was also realized that proper codes for conducting the inventory and inspection do not exist. Absence of codes for selection and conducting of NDT created a major problem. Need for detailed specifications for undertaking remedial intervention was seriously felt. We have 15 documented specifications or guidelines for remedial procedures. An effort to put in place specifications for about 80 odd remedial procedures did not yield any concrete result. Major shortfall in documentation, codes and specifications created an inertia.

During these times, the Minister sent a letter to all Public Works Departments of all state governments to adopt this system on state highways and major district roads to ensure IBMS covers the major portion of Indian road system.

Various state governments are groping in the dark while formulating the RFP and work scope for implementing IBMS. Various presentations made by our team and the officers of the ministry in successive Indian Road Congress provided sketchy guidelines to officers of the Public Work department of all state governments and yielded no concrete guidelines on the scope to be adopted for implementation of IBMS in states for state highways and major district roads. Some Municipal authorities too tried to implement BMS but could not move ahead due to paucity of clear vision as to what needs to be done.

SOLUTION FOR FUTURE

Based on the experience of implementation of the first phase of IBMS it was realised that certain major changes and strengthening of the implementation protocol was essential. Some of the major steps essential in rectification of the scenario include: –

- Creating and writing all required codes, guidelines and specifications for various activities within IBMS. This requires exhaustive paperwork and compilation of new codes, documents, guidelines, specifications as none exists today. Unless this exercise is undertaken by institutional bodies like IRC/ IIBE/ ICI, nothing can be achieved. Presently IRC is formulating a modified IRC SP 35 and 40 for inclusion of information about BMS.

- Training civil engineers to undertake the task of Bridge inventory and inspection. The science of Bridge inspection today is more complex from what existed 10 years ago. Today the bridge inspector has to define the cause of distress rather than just identify the distress. In spite of this need, most tenders floated for bridge inspections seek experience from consultants in the area of bridge inspection and maintenance. It is assumed that an engineer with previous experience of bridge inspection can carry out the inspection and identify the cause of distress under IBMS. No formal training exists for bridge inspectors. The engineers who were working on the IBMS project also have stressed time and again the need for such training and proper documentation.

- Training client’s engineers in the Bridge Management system is essential. Owners of bridges need to understand the goals of BMS rather than just restrict to inventory and inspection of their network. Inventory and inspection are the basic modules of data capture and the real task of BMS begins post this data capture. The science of accessing the risk involved, the skills to select optimization options, analysis of collected data to derive the ranking and priority to be accorded to an individual bridge on a network, the decision to rehabilitate or replace based on technical logic and similar decisions are all very complex situations which the owners engineers need to master and derive from IBMS. This expertise cannot be made available overnight but will have to be cultivated by training and having a dedicated team handling such situations, if one is to get the benefit and achieve efficiency from IBMS.

- Ensuring proper budgetary support for Bridge maintenance and management. Clients have to understand that NO CIVIL ENGINEERING STRUCTURE LASTS FOREVER and regular maintenance is required to ensure uninterrupted usage of the bridges during its service life. Such maintenance needs proper budgetary support and the same is essential regularly.

- Having an accreditation system for all personnel involved in IBMS. Only training to inspect engineers or client’s engineers will not be sufficient. We have over 170,000 bridges and culverts on national highways and probably three to four times that number on the state highways. To maintain such a humongous inventory efficiently, we shall need over 1000 trained bridge inspection engineers and bridge rehabilitation experts. To ensure that these inspection and rehabilitation engineers have a high level of training and expertise, it is essential to have a National accreditation system to grade and categorise all personnel working on IBMS. All engineering personals working on IBMS shall have to undergo regular upgrade/ refresher courses and testing to check the level of expertise. All this can form part of the accreditation system.

- Setting up a core group of engineers from all stakeholders (Bridge owners, consultants, rehabilitation contractors, raw material manufacturing companies) to formulate the future development and research into Bridge Management. As multiple systems may evolve due to divergent needs of multiple owners, it is essential to have a common minimum platform configuration for all such systems. It is also essential to define the future needs of the system and the research which still needs to be undertaken to have a better understanding of the behaviour of the bridges under varied geographical and environmental conditions.

INSTITUTIONAL FRAMEWORK FOR IBMS:

The owners of the bridges (central government and state government) need to come together with all stakeholders involved in implementation of IBMS to form an independent organization which will regulate and formulate the appropriate process to implement IBMS in the country.

Most of the suggested actions are easy to implement through such an organization. This organization could act as a Center of excellence for IBMS with a pool of experts dedicated to further enhancement in IBMS. All formulation of the codes, guidelines, specifications, documents essential for the seamless implementation of IBMS can be published by this organization. The organization could formulate the syllabus essential to train various levels of engineers essential and then provide an accreditation mechanism for them to register and work on the system. Regular courses could be conducted to appraise the various state government officers about the innovations and details of development happening in IBMS, thereby ensuring that they are able to extract the maximum benefit from the system.

Each state network is unique and would need that special modification in the system. This organization could provide required manpower to any government department to start the process of implementation of IBMS.

This organization will help, assist and regulate the entire process of developing and implementing IBMS on various road networks. It can give focus to the needs of research and act as a nodal point for such actions.

CONCLUSION

Much has been achieved by development and implementation of IBMS on the national network. Data collected through 6 repeat cycles is a valuable national asset. Experience and knowledge garnered by the engineers of the department and consultants involved in implementation of IBMS is national wealth. All this cannot be allowed to be lost with time. However, to be able to implement IBMS more effectively, one has to overcome the shortcomings of the previous project. Initiating the formation of a dedicated Institute for IBMS would go a long way in ensuring sustenance of the system and wealth of knowledge secured in the first phase of implementing IBMS.

Any system of asset management provides benefits over prolonged application of the system and to ensure this is done professionally, an institutional framework would be essential.

About the author:

The article is authored by SACHIDANAND JOSHI, Emeritus Chair—IBMS @ IDDC Engineers Pvt. Ltd.

All of the author’s career has been devoted to the Rehabilitation of structures. He has been a team leader to over 2000 inspection, repair and rehabilitation projects. Having seen the various causes of distress so closely and the extent of damage and loss that is caused by ZERO maintenance of various structures, he decided to devote his energy to conceptualize a system that can avoid this scenario. From that urge to minimize distress, came his focus on Asset Management Program.

SACHIDANAND JOSHI is presently working passionately to implement Asset Management Programs in various facades of the Civil Engineering industry in India. The author has ha flair to conceptualize projects and get the team to complete the micro-planning.