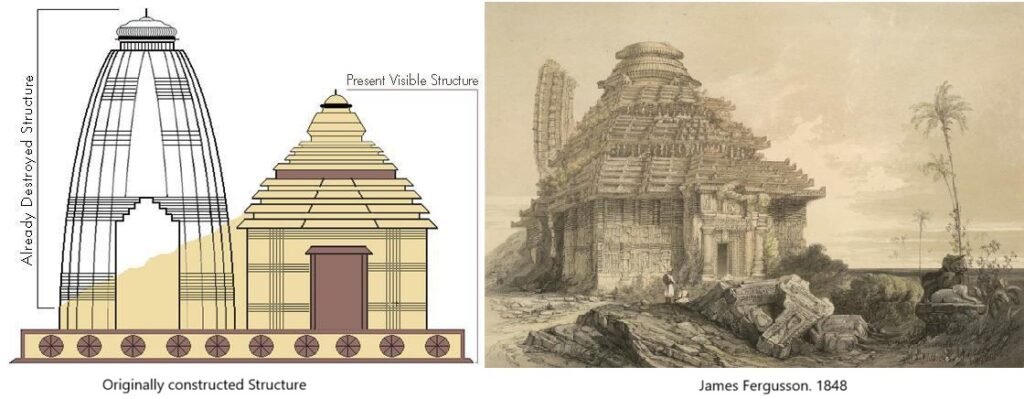

The Sun Temple at Konark, located in Odisha, stands among India’s most celebrated UNESCO World Heritage Monuments. Constructed in the 13th century (c. 1250 CE) during the reign of King Narasimhadeva I of the Eastern Ganga dynasty, the temple represents the pinnacle of Kalinga architectural achievement and medieval Indian engineering.

Conceived as a colossal stone chariot dedicated to Surya, the Sun God, the temple was originally adorned with twenty-four intricately carved wheels and seven sculpted horses, symbolising the cosmic passage of time and the movement of the sun across the heavens. European historians later referred to the monument as the “Black Pagoda”, a reference to its dark khondalite stone and its historical prominence as a navigational landmark along the Odisha coastline.

While the main sanctum (Vimana) collapsed several centuries ago, the Jagamohana (assembly hall) remains the most prominent surviving structure and the principal symbol of Konark’s global heritage value. Surrounded by legend, speculation, and historical theory, the monument continues to stand as a testament to India’s medieval architectural genius and structural ingenuity.

Early Documentation and Colonial-Era Understanding

The first systematic architectural documentation of the Konark Sun Temple was undertaken by James Fergusson in 1848. His studies laid the foundation for future conservation understanding and formal structural interpretation of the monument.

By the late nineteenth century, British engineers and archaeologists began to identify growing structural vulnerabilities within the Jagamohana. Concerns centred on the stability of its massive masonry walls, the internal construction system, and the long-term durability of the materials under coastal environmental stress.

Material Vulnerability and Structural Distress

The temple is constructed primarily of khondalite stone masonry, a metamorphic rock that, while strong in compression, is highly susceptible to environmental degradation. Konark’s coastal location exposed the structure to multiple long-term stress factors:

- Salt-laden winds

- High atmospheric humidity

- Cyclonic weather conditions

- Accelerated coastal weathering

By the late nineteenth and early twentieth centuries, stone fragments from the interior of the Jagamohana began to dislodge and fall, triggering serious concerns about progressive structural failure and the risk of partial or total collapse.

The British Sand-Filling Intervention (c. 1900)

Faced with increasing instability and lacking modern structural engineering solutions, British and Indian engineers implemented a major conservation intervention around 1900.

Key Measures Implemented

- All entrances to the Jagamohana were sealed with thick masonry retaining walls

- The entire internal void was filled with sand sourced from the nearby Chandrabhaga River

- Sand was compacted laterally and vertically, introduced through an opening in the roof up to the crown level

- The intervention was formally documented through Archaeological Survey of India (ASI) drawings dated 1903

- A stone plaque installed in 1903, still visible today, records this historic intervention

Purpose and Long-Term Consequences

The sand fill functioned as an internal buttress, stabilising the structure against lateral movement and wall failure. While structurally effective, the intervention created long-term consequences:

- Complete loss of access to the Jagamohana interior for over a century

- Permanent dependence on the sand mass as a structural support system

Both colonial-era ASI authorities and post-Independence Indian archaeologists meticulously documented this intervention, creating a continuous institutional record that remains available for scientific reference.

Post-Independence Investigations and Scientific Debate

From the 1950s onward, the Archaeological Survey of India (ASI), under the Ministry of Culture, Government of India, initiated periodic assessments to determine whether the sand fill should be retained or removed.

Earlier Investigations

These studies included:

- Boroscope inspections

- Limited internal probing

- Structural evaluations by the Central Building Research Institute (CBRI)

CBRI ultimately recommended retaining — and even increasing — the sand fill, citing the high probability of structural collapse if the internal support system were disturbed. Over time, however, the sand experienced settlement, leading to the formation of a void near the crown of the Jagamohana.

Renewed Scientific Approach (2020–2023)

With advances in non-destructive testing (NDT), LiDAR scanning, digital documentation, and finite-element structural modelling, ASI revisited the question of sand removal.

Between 2020 and 2023, two major scientific conferences were organised, involving ASI, IIT Madras, and other multidisciplinary experts. The discussions focused on unresolved technical questions:

- What lateral pressure does the sand exert on the masonry walls?

- Are the induced shear forces within safe structural limits?

- What is the actual wall thickness and internal masonry configuration?

- Can sand removal be undertaken safely, and if so, through what sequence and methodology?

Given the monument’s global significance and sustained visitor interest, reopening the Jagamohana interior to the public was identified as a potential long-term objective, subject to structural safety.

Pilot Core Drilling: Objectives and Methodology

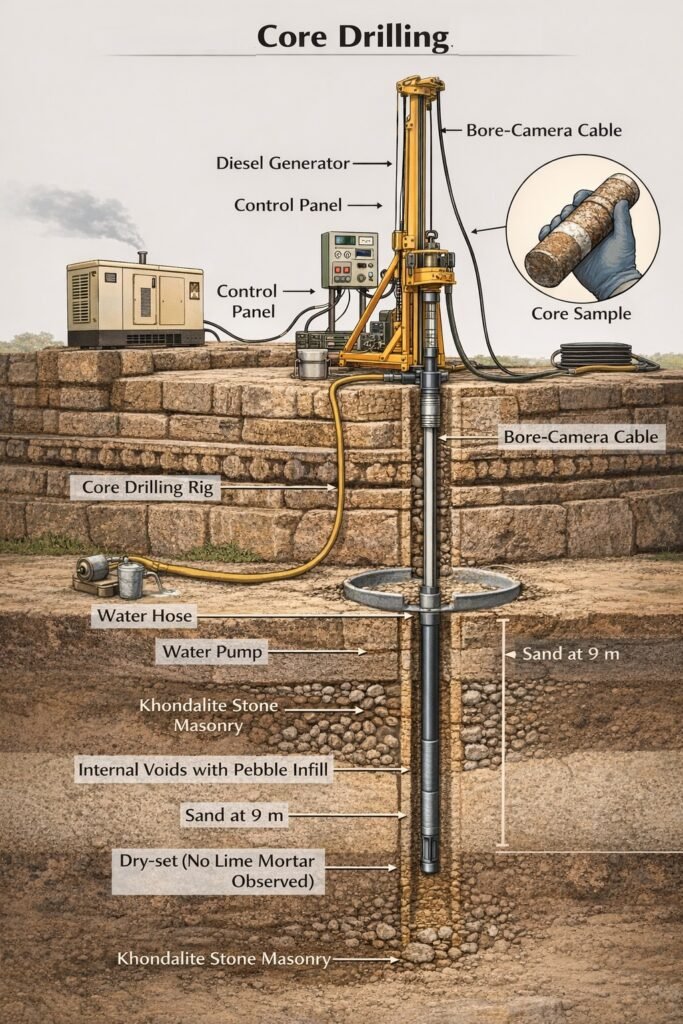

To obtain direct physical evidence, ASI and IIT Madras engaged Advanced Construction Technologies (P) Ltd (ACT), Chennai, led by Er. Mohan Ramanathan, to execute two vibration-free horizontal pilot core drillings within the Jagamohana.

Technical Specifications

- Core diameter: 160 mm

- Elevation: Approximately 15 m above ground level

- Location: Between the 1st and 2nd Peeda levels

- Expected wall thickness: ~10.0 m

- Equipment: Diamond core drilling system by Cedima GmbH (Germany)

Specially designed diamond bits were fabricated to address the abrasive nature of khondalite stone. The drill string configuration ensured:

- Maximum core recovery

- Precise horizontal alignment

- Zero percussive force

Vibration levels were continuously monitored by IIT Madras and found to be negligible in all three axes throughout the operation.

Objectives of the Drilling Exercise

The pilot drilling programme was undertaken to:

- Recover intact masonry cores

- Verify actual wall thickness at two elevations

- Extract sand samples for geotechnical testing

- Identify internal voids and construction techniques

- Generate accurate input data for structural modelling and sand-removal planning

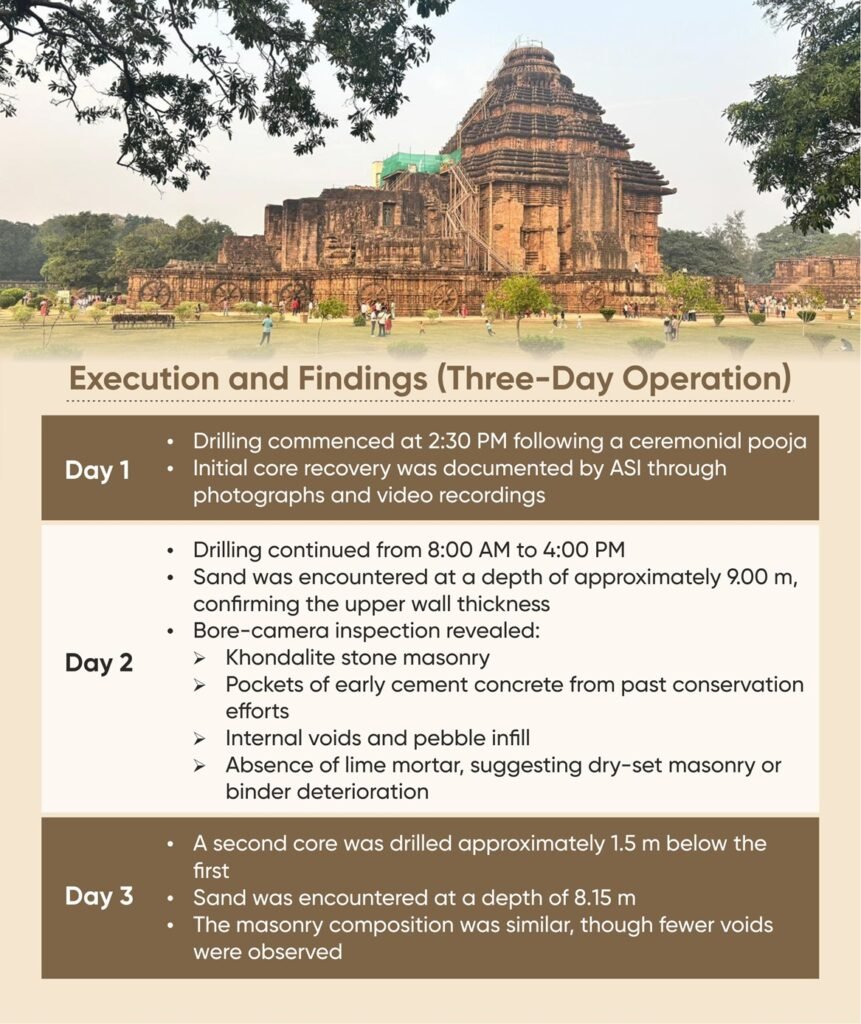

Significance of the Findings

For the first time in over 125 years, ASI now possesses direct physical confirmation of:

- Variation in Jagamohana wall thickness

- Internal void distribution and stone arrangement

- Condition of the sand–masonry interface

These findings enable:

- Accurate structural and finite-element modelling

- Determination of safe load thresholds

- Informed decision-making regarding controlled sand removal, if feasible

The data will play a central role in defining future conservation methodology aimed at safely reopening the Jagamohana interior while ensuring long-term structural stability.

Way Forward

The Konark Sun Temple remains a masterpiece conceived to endure centuries of sun, wind, and time. The recent ASI-led scientific investigations mark a historic milestone in Indian heritage conservation—one that carefully balances public access with engineering responsibility. The future now rests on evidence-based conservation, not assumption.

Acknowledgements

Advanced Construction Technologies (P) Ltd (ACT) gratefully acknowledged the contribution of M/s Abcon Concrete Surgeons (P) Ltd, Bengaluru. Abcon Concrete Surgeons provided specialised expertise in vibration-free drilling and controlled structural intervention, ensuring safe data extraction while preserving the monument’s structural integrity.

About Abcon Concrete Surgeons

Abcon Concrete Surgeons specialises in controlled dismantling, repair and retrofitting, and advanced waterproofing of RCC structures and civil engineering projects. Recognised as pioneers of Concrete Surgery in India, the company introduced diamond cutting technology to the country in 1992.

Their expertise lies in executing safe dismantling, repair, and retrofitting operations while preserving original structural behaviour and visual authenticity. With deep site experience and strong structural engineering knowledge, the company delivers precise, reliable, and minimally disruptive solutions using modern machinery and state-of-the-art techniques, ensuring safety, efficiency, and minimal downtime.

About the Archaeological Survey of India (ASI)

The Archaeological Survey of India (ASI), under the Ministry of Culture, Government of India, is the nation’s premier authority for archaeological research, excavation, and monument conservation. Headed by a Director General and supported by a multidisciplinary cadre of archaeologists, engineers, architects, scientists, and conservation professionals, ASI is responsible for the protection, documentation, and management of more than 3,650 centrally protected monuments and heritage sites across India.

Its mandate spans excavation, scientific research, conservation engineering, heritage policy, and public engagement, positioning ASI as one of the largest and most comprehensive heritage management institutions in the world.