Metal foam panels are lightweight sandwich structures with a porous metal foam core placed between two solid metal sheets. The foam core contains many gas-filled voids, which make the panels extremely light while still providing good strength. These voids may be open-cell (connected) or closed-cell (sealed). Open-cell foams allow air or fluids to pass through, making them useful for filtration, sound absorption, and cooling. Closed-cell foams trap gas inside each cell, offering better strength and thermal insulation by reducing heat transfer.

The metals used for both the foam and the face sheets can include aluminium, steel, titanium, or other alloys. Aluminium is most commonly chosen because it is lightweight, corrosion-resistant, and easy to work with. The final product is a stiff, multifunctional panel that engineers use in many applications by combining the metal foam core with strong outer sheets.

Advantages of Metal Foam Panels

- Lightweight and strong at the same time – helps to lessen the structural load and makes the building design more simple.

- Ability to absorb a large portion of energy – can be used without a problem in the production of the most-resistant-to-impacts façades, barriers and protective zones.

- Excellent thermal insulation – leads to building energy efficiency and less HVAC demand.

- Sound-absorbing capability – contributes to the reduction of noise that comes from the walls, partitions, and can/machine enclosures.

- Fire-proof – the metal skins that are non-combustible make the buildings safer.

- Flexible design – can be used in various thicknesses, profiles, and finishing for the façades, the roofs, and the interiors of the buildings.

- Strong and protective- the product is corrosion resistant and can withstand environmental changes.

- Environmentally friendly – the use of recyclable materials, energy needed for transport is lower and the carbon footprint is reduced.

- Time-saving and hassle-free installation – lightweight components that are prefabricated help in reducing labour and equipment requirements.

Applications of Metal Foam Panels in Constriction

1. Structural Applications

- Light and durable walls, floors, and roofs

- Non-structural walls in modular and prefabricated buildings

2. Thermal Insulation

- Exterior walls and building cladding

- Roofs and ceiling panels

- Cooling rooms or temperature-controlled facilities

3. Acoustic Applications

- Soundproofing walls and partitions

- Ceilings in offices, concert halls, or industrial buildings

4. Fire-Resistant Applications

- Fire-walled partitions

- Fire doors and protective panels

- Cap or cover for extra fire safety

5. Safety & Impact Protection

- Protective walls around industrial sites

- Structures that are blast-resistant or earthquake-resistant

- Security measures for vital infrastructure

6. Flooring Systems

- Industrial platforms and mezzanine floors

- Lightweight temporary floors for construction sites

7. Façade & Aesthetic Applications

- Architectural cladding

- Decorative panels for modern building exteriors

8. Sustainable & Green Construction

- Environmentally friendly buildings utilizing recyclable metal foams

- Energy-efficient retrofitting projects

9. Roofing Systems

- Industrial warehouses and commercial roofs

- Use of insulation, sound absorption, and lightweight support

10. Seismic-Resistant Structures

- Buildings located in areas with frequent earthquakes

- Structures that need energy absorption and vibration damping

Types of Metal Foam Panels

Metal foam panels may be categorized according to their foam, framework, or even the target utilization. Comprehending these kinds is absolutely necessary when figuring out which panel to use for a certain work.

1. Based on Foam Structure:

Open-cell foam panels: The pores in the core are connected, thus the structure resembles a sponge. Such panels find their uses in places where there is a necessity for airflow, heat exchange, filtration, or sound absorption. They are a little less stiff than closed-cell ones but gain through thermal management and acoustic applications.

Closed-cell foam panels: The pores are separate, thus each one is a small pocket of gas. These panels are very stiff and structurally strong and at the same time able to provide thermal insulation. They are utilized in the building envelopes, refrigerated facilities, and areas where there is a need for the fire resistance to be increased.

2. Based on Base Metal:

Aluminum foam panels: The aluminum foam panels are a very light material and at the same time resistant to corrosion. They are very much suitable for applications in the construction, automotive, and aerospace sectors. The popularity of aluminum foam panels stems from their easy fabrication and recyclability.

Steel foam panels: They are heavier than aluminum, but their strength is very high. Are generally found in the industrial safety barriers, the regions that require impact protection, and heavy structural applications areas.

Titanium foam panels: Being extremely resistant to corrosion and biocompatible, titanium panels find their applications in the aerospace sector, marine industry, and biomedical devices such as bone scaffolds.

3. Based on Panel Configuration:

Single-face panels: These types of panels consist of one metal face sheet only, while the other side which is the foam is left unexposed. Primarily they are put to use in the decorative and the acoustic fields.

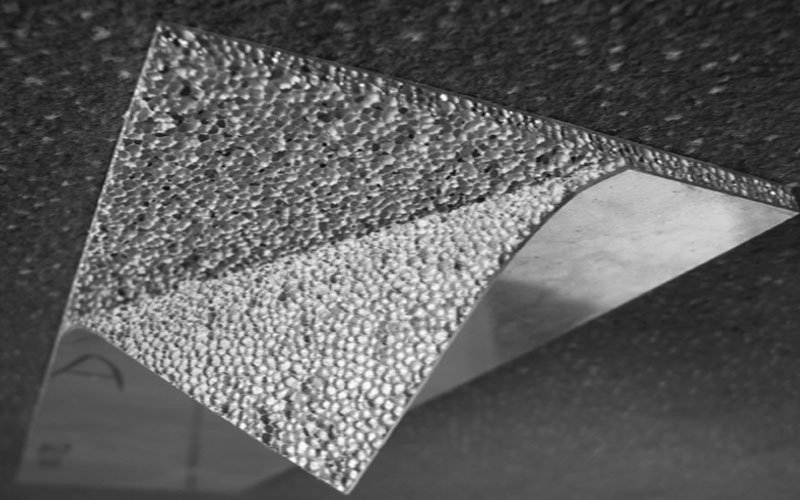

Sandwich panels: The prevailing kind of panels, having metal sheets on both sides and a foam core in between. They give a very good combination of strength, thermal insulation, and energy absorption.

Multi-layer panels: Those are the types of panels which have several alternating layers of metal and foam, thus allowing for enhanced structural performance, better fire resistance, or improved thermal control.

4. Based on Functionality:

Thermal insulation panels: Their primary role is that of energy efficiency. These panels are endowed with a high R-value. Thus they are put to use in the cold storage facilities, industrial refrigeration, and energy-efficient buildings.

Acoustic panels: They are designed to absorb sound. The primary areas of use for these panels are noise abatement in the industrial, urban, and transportation sectors.

Impact-resistant panels: Have a design which allows them to absorb energy and thus be able to provide the necessary protection

Challenges and Considerations

Regardless of the great number of great metal foam panel features, this product still has some drawbacks. The process of their production is complicated and, for this reason, expensive, especially in cases when there is a need for a very accurate control of pore size and density. The variation of the foam properties can result in differing mechanical and thermal performances. In addition, the way in which these panels are joined and repaired should be done in such a way that the overall structural strength as well as the insulation are not interrupted. At last, while metals can be recycled, the method of separating the foam from the face sheets for recycling may be difficult depending on the bonding method.

Future Directions

Innovations in metal foam panels are not settling but still continue to find ways to enhance their usage and broaden their applications. Upcoming trends include introducing panels with customized pore structures for given thermal, acoustic, or mechanical needs, implanting on advanced materials such as microlattices or graphene foams, and making more eco-friendly manufacturing processes. Metal foam panels will, furthermore, be allowed to have an even bigger share of clean building design, modular construction, and advanced transportation systems, where their conglomeration of lightweight, insulating, and structural properties gives the most exceptional advantages.

Conclusion

Metal foam panels are an advanced, multifunctional material that combines strength, lightness, and insulation in a single product. Their unique combination of properties—lightweight structure, energy absorption, thermal and acoustic insulation, fire resistance, and design versatility—makes them valuable in a wide range of industries, from construction to aerospace and transportation. While manufacturing challenges and costs remain considerations, ongoing research and innovation are expanding their capabilities and making them increasingly accessible. As industries strive for sustainability, energy efficiency, and high-performance solutions, metal foam panels are poised to become a cornerstone of modern engineering and construction design.