This article introduces the methodology for durability design of concrete repairs for infrastructures affected by deterioration in mid-life. A change of design approach is recommended, from the conventional “prescriptive approach” practiced by current design standards to performance-based approach” which considers the actual ageing process through probabilistic treatment. Corrosion of steel reinforcement is considered as the most critical process and subject to performance-based design. The target design-life and durability limit states are attributed to concrete elements according to their desired maintenance free life. This article is based on experience of the author in dealing with durability assessment of infrastructures.

1.Motivation

Signicant amount of national funds are invested worldwide in the construction of infrastructure required to support society’s needs. In India it was forecasted that an investment of about Rs. 65 lakh crores in infrastructure was required for the 12th five year plan [Planning Commission]. Such high initial cost of infrastructure justies the importance of durability for such facilities. However existing infrastructure is undergoing deterioration faster than predicted, because the mechanism of degradation was not understood well at the time of construction and was not taken into account in the planning [Faroz and Ghosh, 2017]. As a result infrastructures such as bridges have degraded well before their expected service life is reached. As a result extensive repairs are needed for such infrastructures. In U.S., the annual cost for repair, maintenance and strengthening is estimated between $18 and $21 billion [Emmons and Sordyl, 2006]. Similar estimates can be expected for our country. Additionally, hindrance to the usability of facilities because of repair works cause signifcant revenue loss.

Corrosion of reinforcement steel is the leading cause of deterioration of reinforced concrete structures. Figure 1 shows visual of corrosion a affected bridges. Corrosion is conditioned on the uncertainty associated with the concrete construction, e.g. environmental exposure, early-age cracking, unintended lower concrete cover, accidental use of saline water for concrete mixing and/or curing. Joshi et al. [2018] highlights an example where a reinforced concrete bridge started corroding within two years of its inauguration because saline water was used for its curing. Such structures needs to be repaired by total concrete recasting of the covercrete which is economically expensive. Even after repairs are completed, questions still remain in the conscience of the Asset owner:

How long will the repairs last?

How long before the next repair is due?

This is because premature failure of repaired concrete structure as well as performance of the majority of repaired concrete structures affects many countries. A, CON REP NET study found out that only 75% of repairs survive 5 years, 25% of repairs survive 10 years and only 5% survive 25 years [Vimmr, 2004].

This article introduces the aspect of the performance based service life design of repaired concrete structures, with an aim of ensuring a maintenance free life. Such approach is part of Infrastructure Risk Management, which allows better utilisation of available resources [Faroz, 2018b]. This article is based on experience of the author in dealing with durability assessment of infrastructures [Faroz, 2018a,c].

2. Repair Through Concrete Recasting

This technique involves full/partial depth replacement of the contaminated concrete. The concrete can be contaminated by chlorides or may be carbonated, which promote corrosion initiation. Figure 2 shows schematically various methods of repair by recasting.

3. Concrete Durability

Concrete durability problems arise from the aggressiveness of the environment to which the structure is exposed. The chloride-induced corrosion is the most critical processes for durability design. The main reasons for such durability problems are the interconnected porous nature of the hydrated cement paste and the heterogeneity of concrete properties. Better quality control in the selection of materials and processes on site can control the problems related to the concrete system.

In the construction industry, durability is expected to be achieved through strength. But there is no simple or unique relationship between strength and any of the durability parameters. The key to concrete durability is the achievement of a “designed concrete pore structure”. The simple way towards this goal is by specifying the concrete accurately for its intended purpose. The specification should address different aspects such as intended service-life, quantifiable description regarding serviceability requirement and failure, acceptable level of risk and possible extent of maintenance.

3.1. Conventional durability aspect

Conventionally, the durability design of a concrete structure for a target working life is achieved using a “prescriptive (deemed-to-satisfy) approach”. This approach is followed by most design codes in use (IS 456:2000, IRC 112:2011, IRS CBC:1997). The provisions include limits of:

- Minimum cement content,

- Maximum water cement (w/c) ratio

- Minimum grade of concrete

- Nominal concrete cover

Following these rules the designer could “assume” that the structure would achieve an acceptable long, but unspecified service life. However, the fulfilment of a particular service-life, if all of these prescription are satisfied, cannot be quantified using this approach. In other word, “if all requirements are satisfied, what will be the achieved service-life?”. Thus this approach cannot be used to achieve a desired life of repairs. The “Performance Based Durability Design” is useful for achieving this objective.

4. Performance Based Durability Design

The performance-based approach involves modelling the real ageing process of structural materials under environmental actions and employs mathematical models to evaluate the required properties and structural dimensions for expected design lives through probabilistic treatments. These methods allow the uncertainty associated with all levels of corrosion process to be incorporated into the analysis, leading to a robust and informed design. The performance-based approach is an “engineered approach” to durability design.

4.1. Design Life and Durability Limit State

The asset owner desires a long working life for the infrastructure, which is usually 100 years. However due to unexpected deterioration due to corrosion in an intermediate stage of the life, the design service life of the repairs can be the residual time upto 100 years.

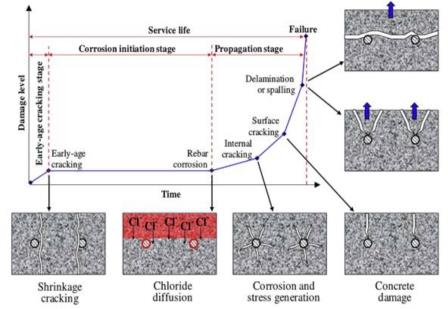

Durability Limit States (DLS) are needed for quantitative durability design using the performance-based approach. These are the minimum acceptable performance levels for different durability processes. The stages in life of a corroding concrete element is shown in Figure 3 for visualising various DLS. From this Figure 3 it is seen that once the chlorides reach the rebar level and accumulate in sufficient quantity, corrosion commences. Further propogation of corrosion leads to cracking of concrete cover and ultimately leading to spalling or delamination. For a “maintenance free” repair it is advised to adopt the limit state of corrosion initiation.

4.2. Design Methodology

Considering structural design of durability for corrosion processes, the design factors are concrete cover quality (diffusivity), concrete cover thickness, and crack control criteria. The concrete cover quality and thickness are designed through the durability models with the target service lives and appropriate DLS adopted. For the performance design procedure, the concrete surface is supposed to be exposed directly to aggressive agents (Cl ). The model-based design follows a reliability analysis format with a target probability of failure (PT ), depending on the life desired (TL) for the repair.

4.3. Design Model

The design model for chloride-induced corrosion is adapted from the analytical model of dilusion. With the DLS specified as the corrosion initiation state, the design equation can be written as,

G = Cth – C(Cs, xd, Dc, TL) (1)

C(:) is the chloride concentration function in concrete. This model has four governing random parameters:

- Threshold chloride concentration (Cth)

- Concrete surface chloride concentration (Cs)

- Chloride diffusion coefficient of concrete (Dc)

- Concrete cover thickness (xd)

The objective being to obtain cover thickness (xd) and speci cations of the concrete such as the chloride diffusion coefficient of concrete (Dc) for the speci ed design life of repair (TL) subject to

P (G < 0)= PT (2)

The four random parameters have significant dispersion for a given exposure condition, and their statistical nature must be taken into account to guarantee a large enough safety margin for the durability design. Towards this aim, the design is performed by a full probabilistic scheme using directly the statistical properties of the parameters.

4.4. Testing of Parameters

The statistical properties of model parameters are analysed on the basis of the long-term in-place structural investigations and exposure tests in vicinity of the proposed project. It is advised to identify these parameters and must be included in the feasibility investigation for the project. The investigation comprises of environmental data extracted from site investigation for atmospheric temperature, humidity, and air-borne chloride content and wind speed. Further, the evaluation of chloride profiles of structures in the vicinity of the proposed project or similar projects elsewhere must be incorporated. This investigation helps to statistically characterise the diffusive property of concrete and evaluate the distribution of surface chloride concentration. Furthermore migration tests are adopted to investigate the concrete to be used in repairs. Since the concrete cover is the only structural parameter in the design equation, correct specification of concrete cover thickness is the central issue for durability design. The statistical properties of concrete cover thickness are important for correct estimation of reliability with respect to the design equation, and are related closely to the construction methods and practice. Statistical analysis based on the data of achieved cover thickness of similar concrete infrastructures must be investigated.

5. Closure

There is massive capital investment on infrastructure in our country. To safeguard these investments and prolong life of costly repairs and renovation, it is prudent to design the properties of concrete cover (its penetrability and thickness). This technical article adopts the performance-based design for the durability design. This article highlights important steps involved in the durability design for to be repaired concrete components.

References

- D. Cusson, Z. Lounis, and L. Daigle. Benefits of internal curing on service life and life-cycle cost of high-performance concrete bridge decks – A case study. Cement & Concrete Composites, 32:339-350, 2010.

- P. H. Emmons and D. J. Sordyl. The State of the Concrete Repair Industry, and a Vision for its Future. Concrete Repair Bulletin, pages 7-14, 2006.

- S. A. Faroz. Performance Based Durability Design of Bridges for 120 Years. Indian Society of Structural Engineers (ISSE) Journal, 20(3):10-15, 2018a.

- S. A. Faroz. Infrastructure Risk Management – Towards an Exciting Future of Bridge Management. The Masterbuilder, 20(7):124-128, 2018b.

- S. A. Faroz. Durability Design Methodology of Metro Rail Bridges for 120 Years. Metro Rail News, 2:26-31, 2018c.

- S. A. Faroz and S. Ghosh. Falling Short but not Falling Down: Challenges and Solution for the Service-Life Estimation of Gradually Degrading Bridges. The Masterbuilder, 19 (7):144-148, 2017.

- M. Joshi, M. Yadav, and S. Gaonkar. Investigation and Retrofitting of RCC Deck Suffering from Accelerated Corrosion. The Masterbuilder, 20(2):150-152, 2018.

- Planning Commission. Infrastructure funding requirements and its sources over the implementation period of the twelfth five year plan (2012-2017). http://planningcommission.nic.in. Last accessed: September, 2018.

- D. Vimmr. Future performance-discussion on industry response to owners’ aspirations. In CON REP NET Network Newsletter No. 4, pages 5-9. 2004.